Integrated sour gas treating process

A treatment process and tail gas treatment technology, which is applied in the preparation/purification of hydrogen sulfide and sulfur, can solve the problems of secondary pollution, large consumption of lye, etc., achieve high sulfur recovery rate, low energy consumption, and flexible process operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

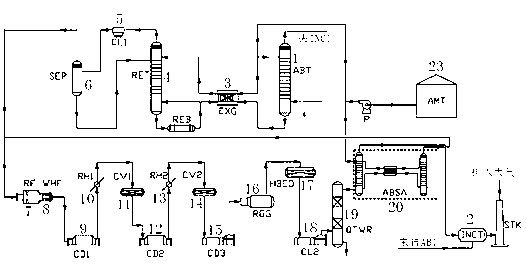

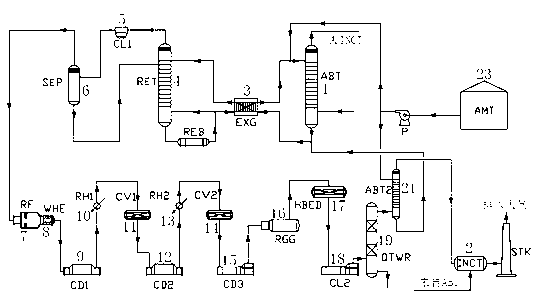

[0022] Such as Figure 1 to Figure 4 As shown, the devices involved in the process of the present invention include: absorption tower (ABT) 1, incineration device (INCT) 2, lean-rich liquid heat exchanger (EXG) 3, regeneration tower (RET) 4, condenser (CL1) 5 , Reflux tank (SEP) 6, combustion furnace (RF) 7, waste heat boiler (WHE) 8, primary condenser (CD1) 9, primary reheater (RH1) 10, primary reactor (CV1) 11, Secondary condenser (CD2) 12, secondary reheater (RH2) 13, secondary reactor (CV2) 14, final condenser (CD3) 15, online combustion furnace (RGG) 16, hydrogenation reduction reactor (HBED) 17. Precooler (CL2) 18. Quenching tower (QTWR) 19. Small acid gas concentration device (ABSA) 20. Amine absorption tower (ABT2) 21. Compressor (CMP) 22. Storage tank ( AMT) 23 et al.

[0023] The purpose of the present invention is to produce low concentration H for natural gas deep desulfurization and decarburization process 2 S sour gas working condition, specially developed sou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com