Precipitating and desalting high-salt wastewater recycling process

A high-salt wastewater and process technology, applied in the direction of flocculation/sedimentation water/sewage treatment, water pollutants, multi-stage water treatment, etc., can solve problems such as interference with chloride ion removal, limited operation effect, and chemical consumption, etc., to achieve process operation Stable and reliable, low operating cost, and reduced corrosiveness of effluent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

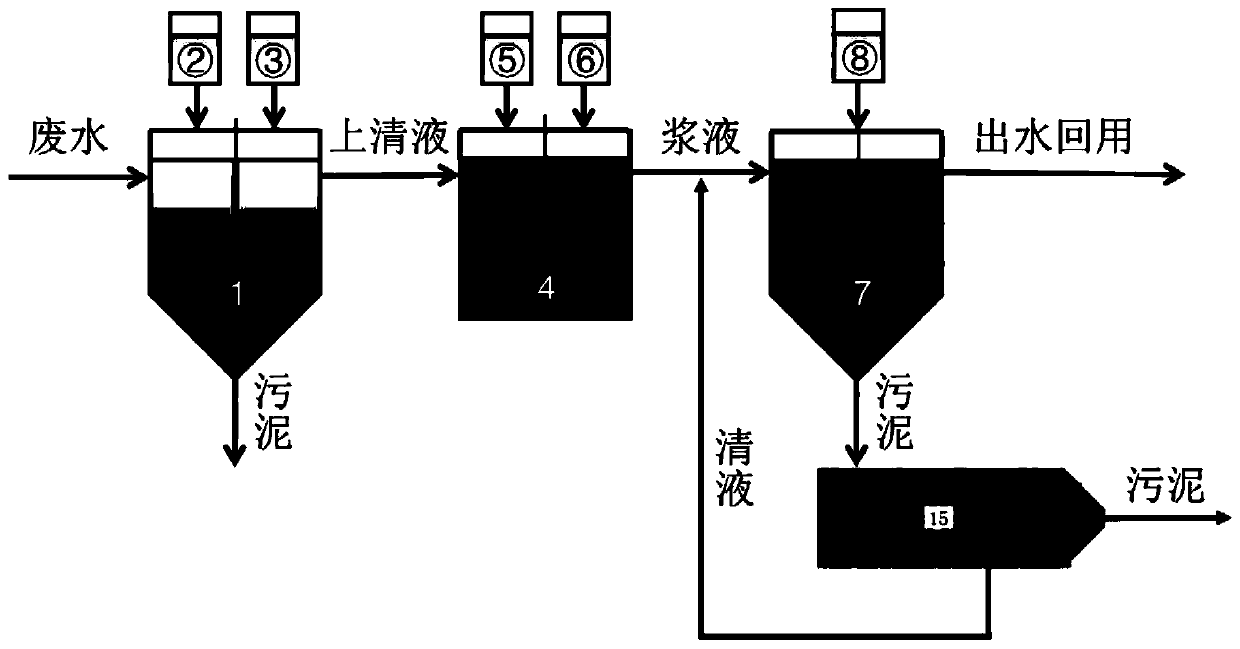

[0059] In this example, the wastewater to be treated is the flue gas desulfurization wastewater of an inland thermal power plant. figure 1 As shown in the process flow, the equipment involved includes a preliminary desulfurization tank 1, a deep desalination tank 4, a sedimentation tank 7, and a dehydrator 15 connected in series, wherein the preliminary desulfurization tank 1 is connected to the first dosing tank 2 and the first flocculation dosing Box 3, deep desalination tank 4 is connected to the second dosing tank 5 and the third dosing tank 6, the sedimentation tank 7 is connected to the second flocculation dosing tank 8, and the clear liquid outlet of the dehydrator 15 is connected to the slurry in the sedimentation tank 7 through the return pipe Entrance.

[0060] The specific treatment process of using the above system to treat wastewater is as follows: the pretreated desulfurization wastewater is passed into the preliminary desulfurization tank 1, and the agent A is a...

Embodiment 2

[0064] The nanofiltration concentrated solution of a waste incineration plant contains 5071 mg / L of sulfate radicals and 6794 mg / L of chloride ions. The content is 3270mg / L of chloride ion, using figure 1 Process flow shown. The specific treatment process is as follows: the pretreated smoke washing wastewater is passed into the preliminary sulfur removal tank 1, and the agent A is added through the first chemical dosing box 2 (the agent A is calcium hydroxide, and its dosage is the mole of sulfate radical in water. Concentration 10 times) make it react to generate calcium sulfate precipitation, add flocculant A through the first flocculation dosing box 3 simultaneously to improve sedimentation performance (flocculant A is FeSO4 , the dosage is 5g / L); the hydraulic retention time in the primary desulfurization tank 1 is 2h. The precipitate obtained from the solid-liquid separation in the preliminary desulfurization tank 1 is comprehensively utilized as gypsum after subsequent ...

Embodiment 3

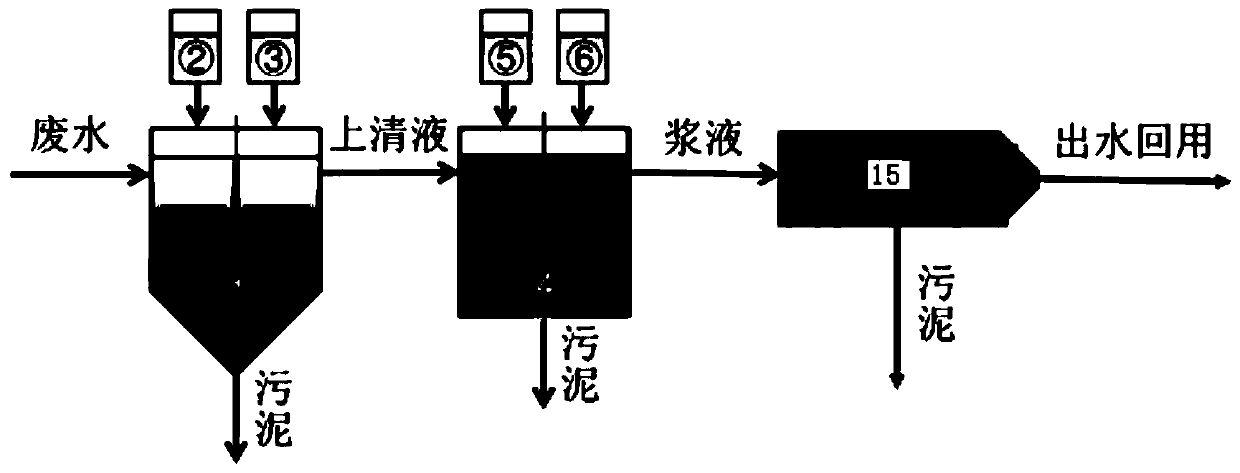

[0067] In this example, the waste water to be treated is the flue gas desulfurization waste water of a Linhai thermal power plant. image 3 The process flow shown, the equipment involved includes a preliminary desulfurization tank 1, a deep desalination tank 4, and a dehydrator 15 connected in series, wherein the preliminary desulfurization tank 1 is connected to the first dosing tank 2 and the first flocculation dosing tank 3, and the depth is The desalination pond 4 is connected with the second medicine adding box 5 and the third medicine adding box 6 .

[0068] The specific treatment process is as follows: the pretreated desulfurization wastewater is passed into the preliminary desulfurization tank 1, and the agent A is added through the first chemical dosing box 2 to make it react to form calcium sulfate precipitation, and at the same time, it is injected through the first flocculation chemical dosing box 3 Add flocculant A to improve the sedimentation performance; the hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com