Softening process for industrial raw water

An industrial, raw water technology, applied in water softening and other directions, can solve the problems of large process area, large water content, low process efficiency, etc., and achieve the effects of wide process conditions, slow grain growth, and simple process operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

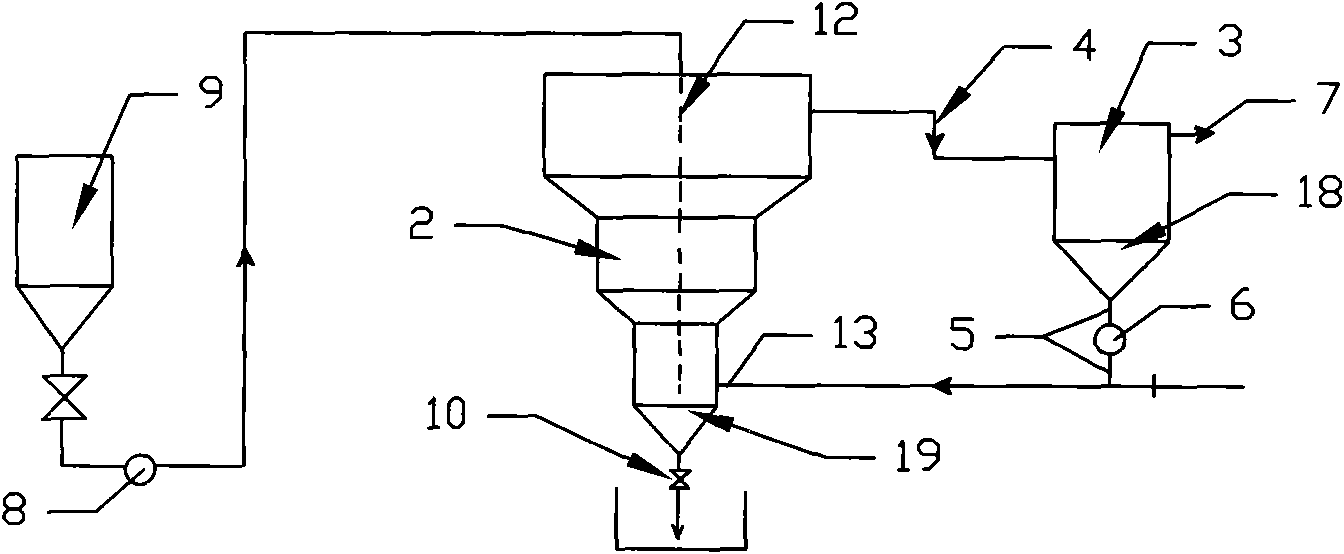

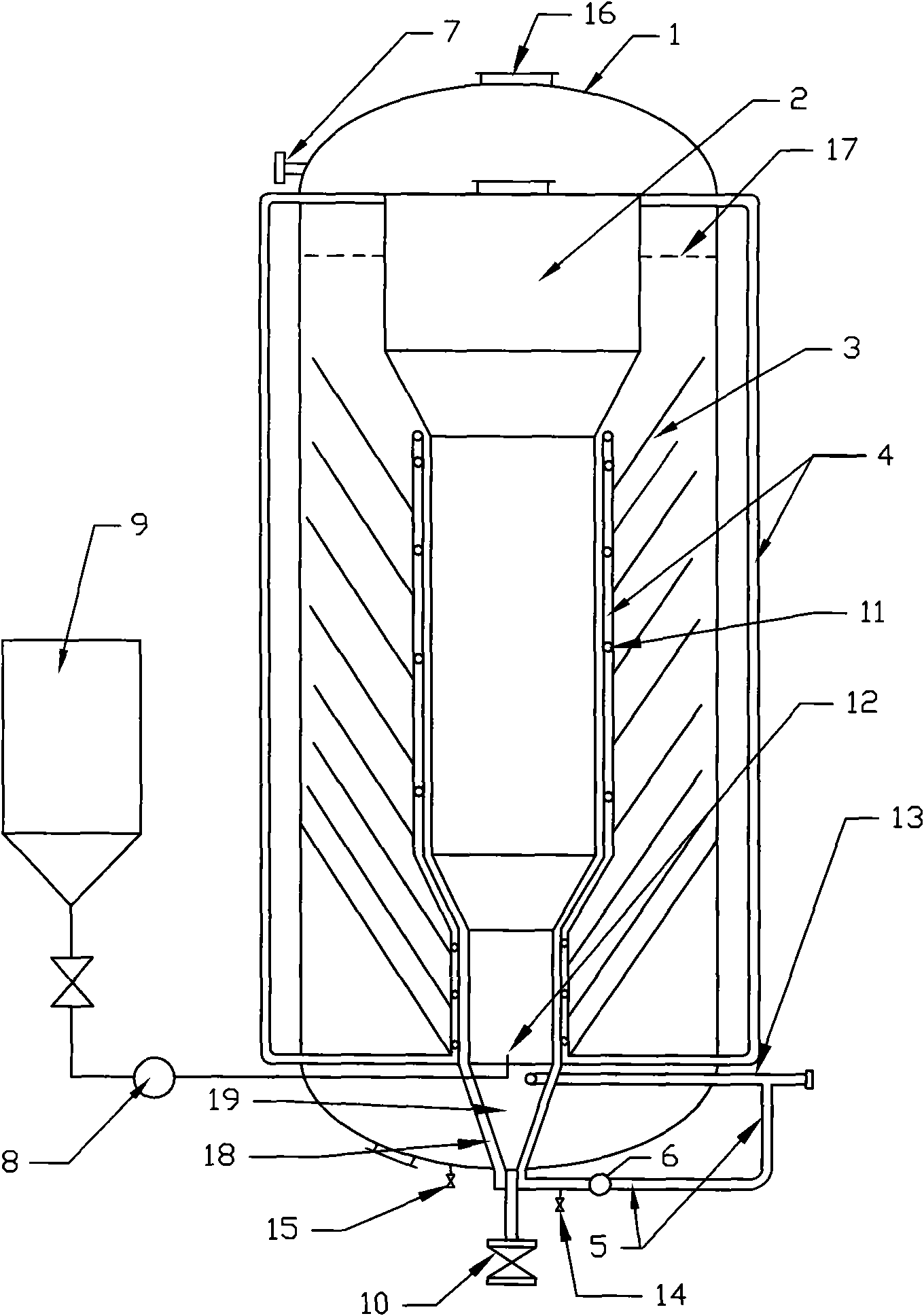

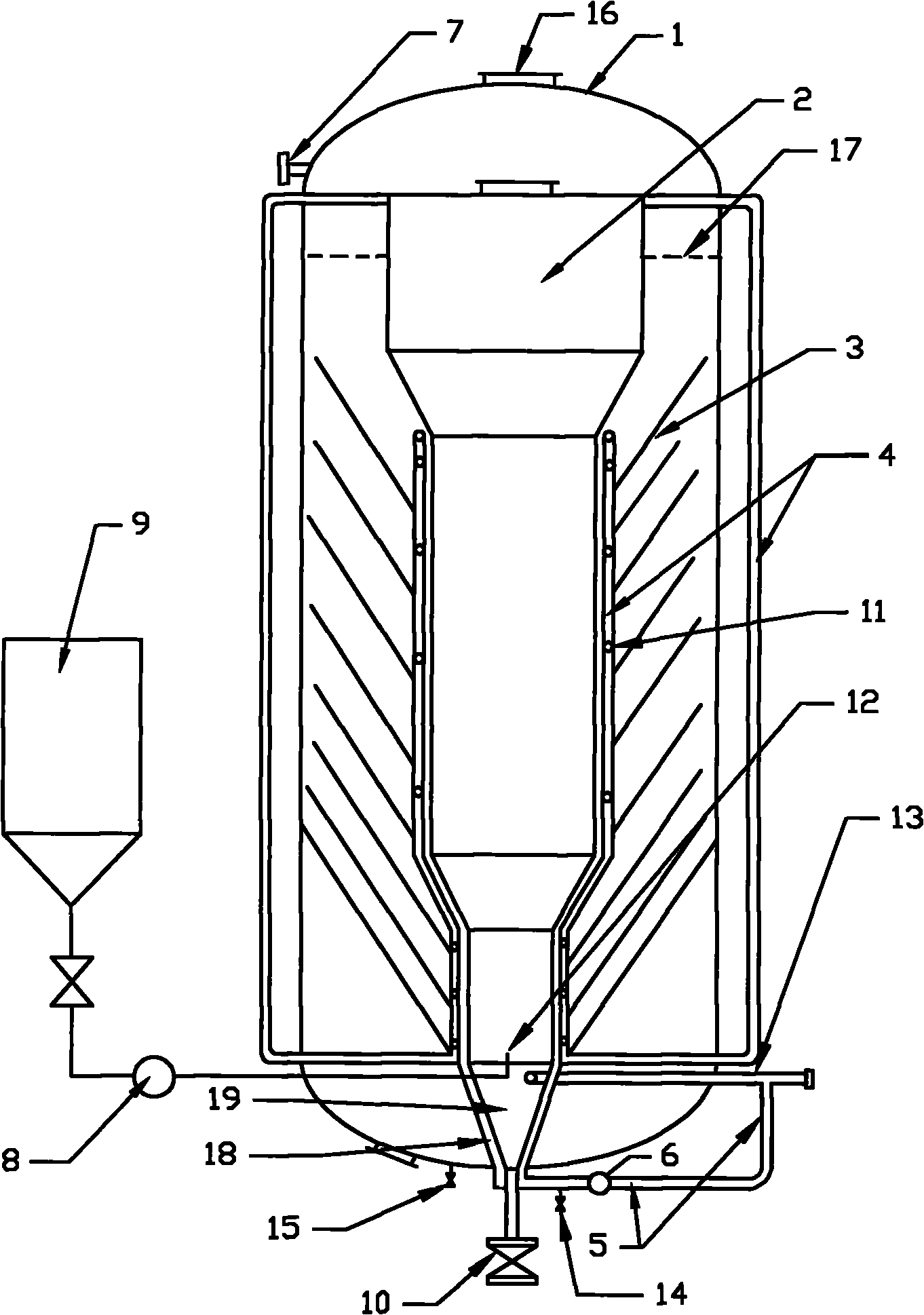

Embodiment 1

[0018] The schematic diagram of the specific implementation is as follows figure 2 : the main body of the cyclone clarifier (2) is placed in the tank body (1); the main body of the cyclone clarifier (2) is composed of three sections of successively increased cylinders and two sections of truncated cone tubes, and the lower part is provided with There is an offset water inlet pipe (13), its upper part is connected to the water delivery pipe (4), and its bottom is provided with a sand discharge valve (10) and a conical inner sand collection bucket (19). The external sand bucket (18) is covered with a certain gap, and the external sand bucket (18) is connected with the sedimentation device (3); a sedimentation device ( 3), the settling device (3) is made up of conical inclined plates; the lower opening between each pair of inclined plates is provided with an annular water distribution pipe (11) connected to the water delivery pipeline (4), and the outer side of the annular water...

Embodiment 2

[0027] The schematic diagram of the specific implementation is as follows figure 2 : the main body of the cyclone clarifier (2) is placed in the tank body (1); the main body of the cyclone clarifier (2) is composed of three sections of successively increased cylinders and two sections of truncated cone tubes, and the lower part is provided with There is an offset water inlet pipe (13), its upper part is connected to the water delivery pipe (4), and its bottom is provided with a sand discharge valve (10) and a conical inner sand collection bucket (19). The external sand bucket (18) is covered with a certain gap, and the external sand bucket (18) is connected with the sedimentation device (3); a sedimentation device ( 3), the settling device (3) is made up of conical inclined plates; the lower opening between each pair of inclined plates is provided with an annular water distribution pipe (11) connected to the water delivery pipeline (4), and the outer side of the annular water...

Embodiment 3

[0036] The schematic diagram of the specific implementation is as follows figure 2 : the main body of the cyclone clarifier (2) is placed in the tank body (1); the main body of the cyclone clarifier (2) is composed of three sections of successively increased cylinders and two sections of truncated cone tubes, and the lower part is provided with There is an offset water inlet pipe (13), its upper part is connected to the water delivery pipe (4), and its bottom is provided with a sand discharge valve (10) and a conical inner sand collection bucket (19). The external sand bucket (18) is covered with a certain gap, and the external sand bucket (18) is connected with the sedimentation device (3); a sedimentation device ( 3), the settling device (3) is made up of conical inclined plates; the lower opening between each pair of inclined plates is provided with an annular water distribution pipe (11) connected to the water delivery pipeline (4), and the outer side of the annular water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com