Coke oven flue gas multi-pollutant dry purification device and process

A technology for coke oven flue gas and purification device, which is applied to chemical instruments and methods, steam generation methods using heat carriers, lighting and heating equipment, etc. and other problems to achieve the effect of avoiding wear, reliable process operation and preventing poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

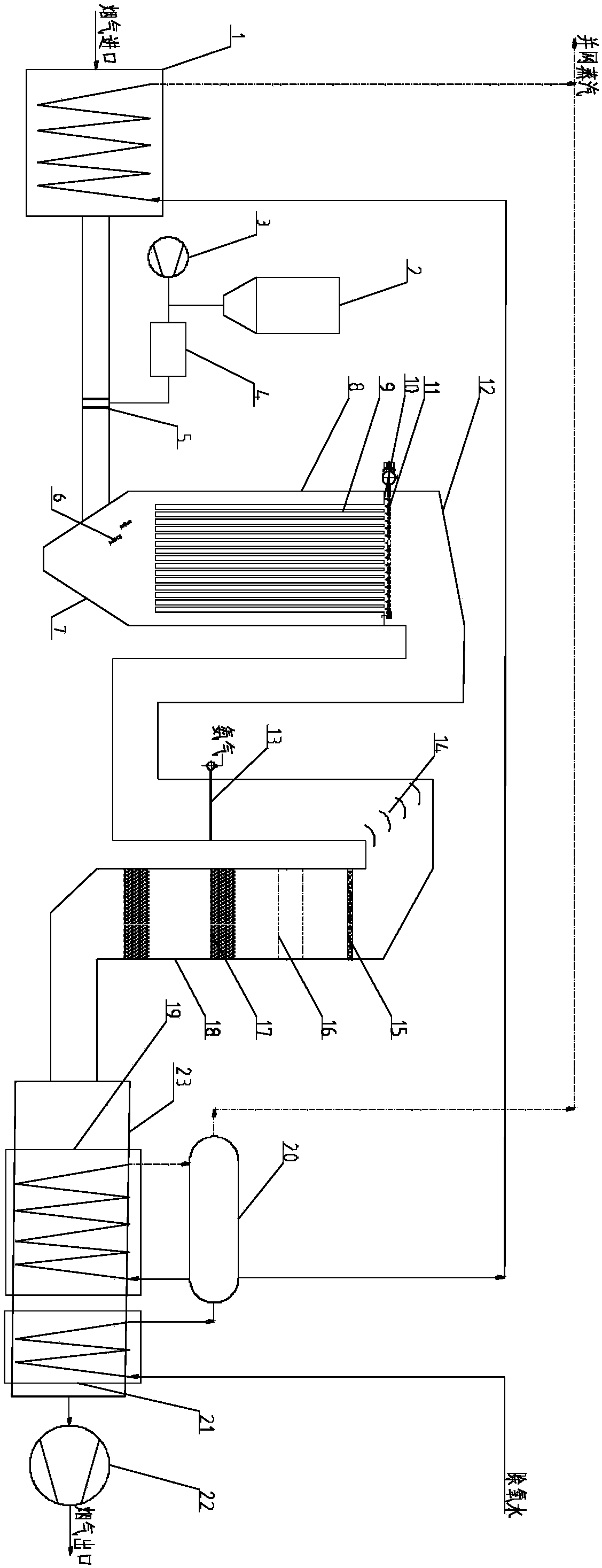

[0026] In order to set forth the specific implementation steps of the present invention more vividly, it will be further described as follows in conjunction with the accompanying drawings:

[0027] With reference to the accompanying drawings, a coke oven flue gas multi-pollutant dry-type purification device of the present invention includes an evaporator I1, a desulfurizing agent feeding and grinding conveying system, a desulfurizing agent dosing device 5, a bag filter, and a medium-low temperature SCR denitrification reaction device 18, waste heat boiler 23 and induced draft fan 22, the evaporator I1 is a heat pipe evaporator, and a coil is installed in the heat pipe evaporator, and the desulfurizer dosing device 5 is arranged between the outlet of the evaporator I1 and the cloth bag Between the inlets of the dust collector, the desulfurizing agent dosing device 5 is connected with the desulfurizing agent grinding and conveying system. The desulfurizing agent grinding and conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com