Continuous esterification production method for plasticizer

A production method and technology for plasticizers, which are applied in chemical instruments and methods, organic chemistry, carboxylate preparation, etc., can solve the problems of inability to achieve large-scale production, large fluctuations in product quality, and restriction of plasticizer output. Shorten production time, stable product quality, and save manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

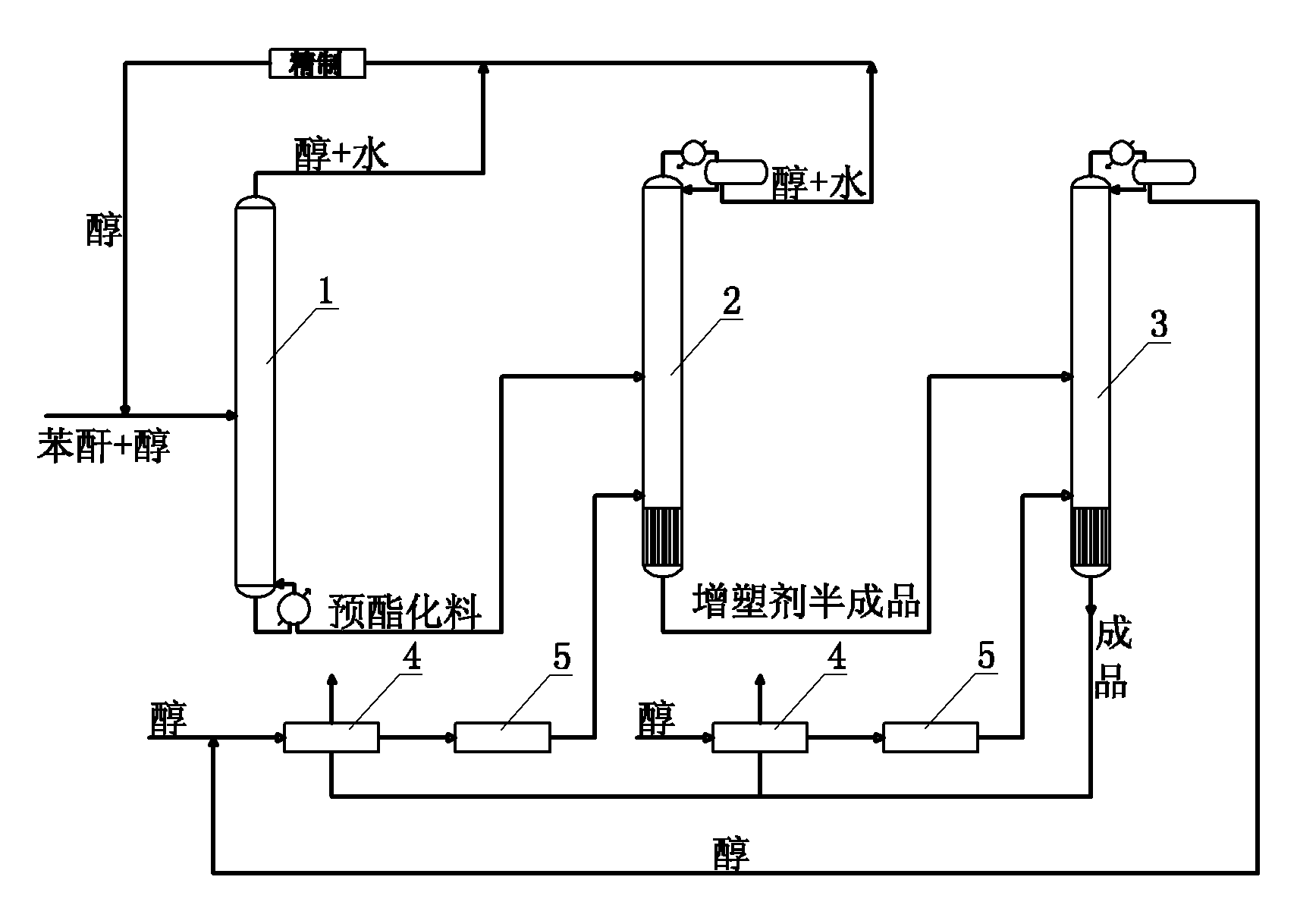

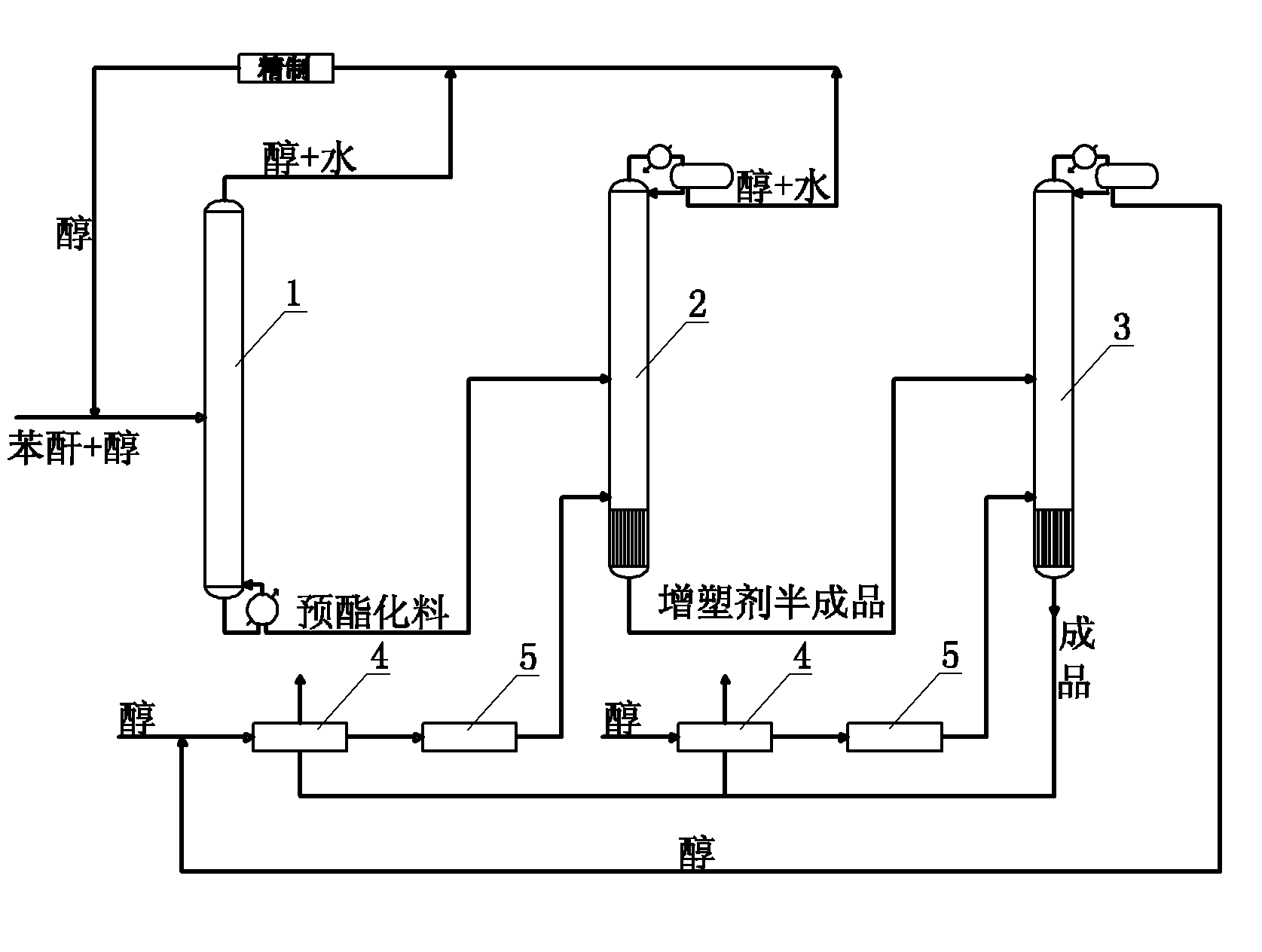

[0032] Mix phthalic anhydride and octanol at a molar ratio of 1:2.7, raise the temperature to 180°C, separate and remove the generated water from the top of the pre-esterification kettle 1, and obtain the pre-esterification material; preheat the octanol through the preheater 4 to 150°C, and then heated to 200°C by the heater 5 to obtain superheated octanol gas; the pre-esterification material is continuously entered from the middle and upper part of the first-stage continuous esterification reactor 2, and the superheated octanol gas is obtained from the first-stage continuous esterification reaction The upper end of the reboiler at the lower part of the device 2 enters, and the superheated octanol gas upwardly reacts with the pre-esterified material entering from the upper part on the catalyst reaction bed. The catalyst is ferric chloride, and the amount of catalyst added is 6wt% of the amount of phthalic anhydride , the bottom temperature of the primary continuous esterificati...

Embodiment 2

[0034]Mix phthalic anhydride and sec-octanol at a molar ratio of 1:2.8, raise the temperature to 170°C, separate and remove the generated water from the top of the pre-esterification kettle 1, and obtain the pre-esterification material; pass the sec-octanol through the preheater 4 first Preheated to 145°C, and then heated to 210°C by heater 5 to obtain superheated 2-octanol gas; the pre-esterified material is continuously fed from the middle and upper part of the first-stage continuous esterification reactor 2, and the superheated 2-octanol gas is fed from the first-stage The upper end of the reboiler in the lower part of the continuous esterification reactor 2 enters, and the superheated 2-octanol gas goes up and the pre-esterified material entering from the upper part undergoes a countercurrent reaction on the catalyst reaction bed. The catalyst is stannous oxide, and the amount of catalyst added is phthalic anhydride 8wt% of the amount, control the bottom temperature of the ...

Embodiment 3

[0036] Mix phthalic anhydride and n-butanol at a molar ratio of 1:2.5, raise the temperature to 150°C, separate and remove the generated water from the top of the pre-esterification kettle 1 to obtain the pre-esterification material; pass the n-butanol through the preheater 4 first Preheated to 130°C, and then heated to 200°C by heater 5 to obtain superheated n-butanol gas; the pre-esterification material is continuously entered from the middle and upper part of the first-stage continuous esterification reactor 2, and the superheated n-butanol gas is fed from the first-stage The upper end of the reboiler at the lower part of the continuous esterification reactor 2 enters, and the superheated n-butanol gas upwardly reacts with the pre-esterification material entering from the upper part on the catalyst reaction bed. The catalyst is titanium dioxide, and the amount of the catalyst added is phthalic anhydride. 5wt%, control the bottom temperature of the primary continuous esterifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com