Spur gear extrusion concave die

The technology of spur gear and concave die is applied to the extrusion die of spur gear extrusion. In the field, the effect of reducing the influence of friction and easy forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

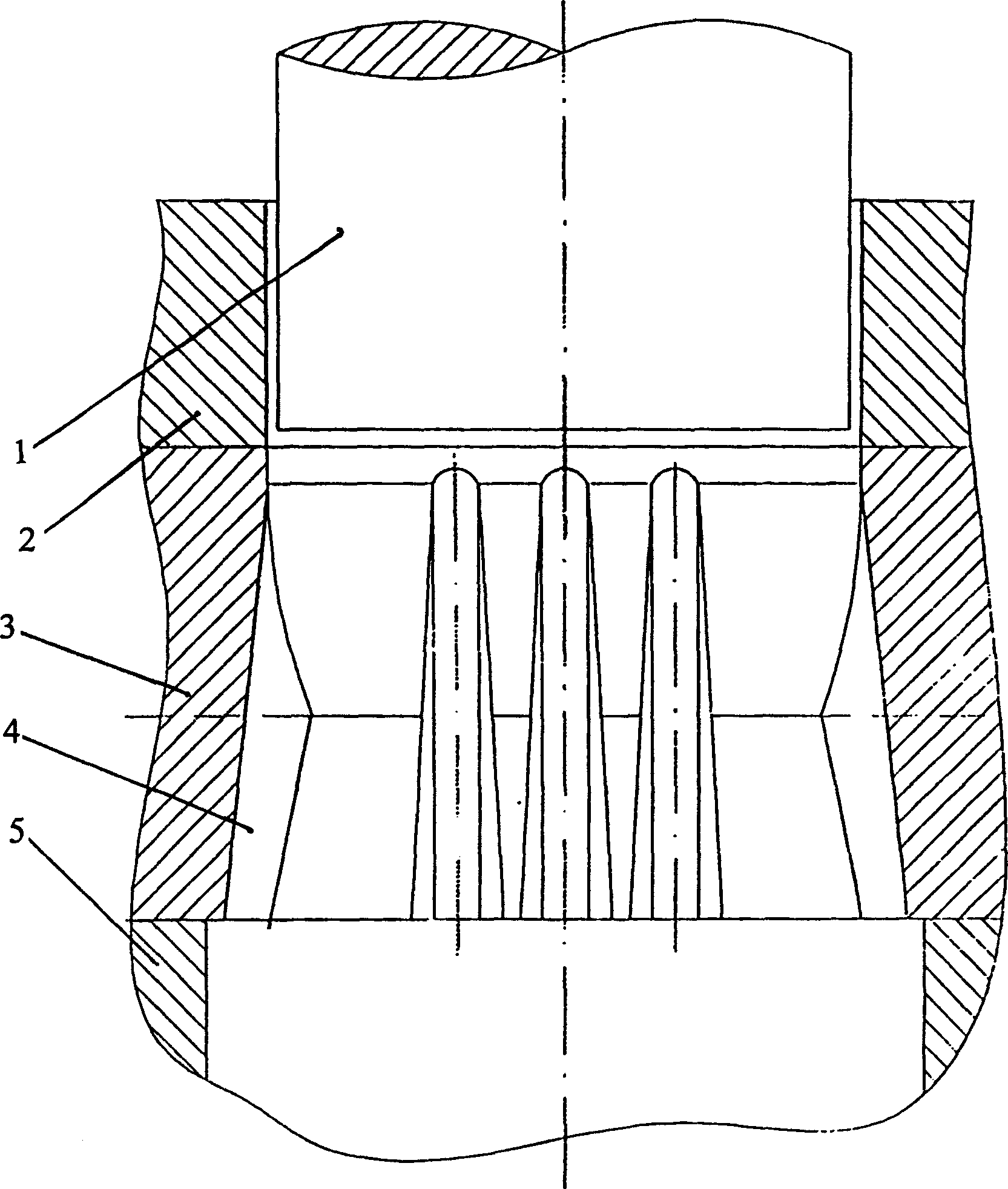

[0020] See attached figure 1 , The die in this embodiment is from the blank inlet to the formed metal outlet, followed by the guide section 2, the forming section 3, the support section 4 and the die backing plate 5. In the guide section 2 of the die, the diameter of the die entrance should be larger than the diameter of the pitch circle of the forming gear and smaller than the diameter of the addendum circle of the forming gear, and the diameter of the blank should be set accordingly. The unilateral gap between the punch 1 and the guide section 2 of the concave mold is not more than 0.15mm. In order to make the support more effective, the forming section 3 and the support section 4 should be designed as an integral structure.

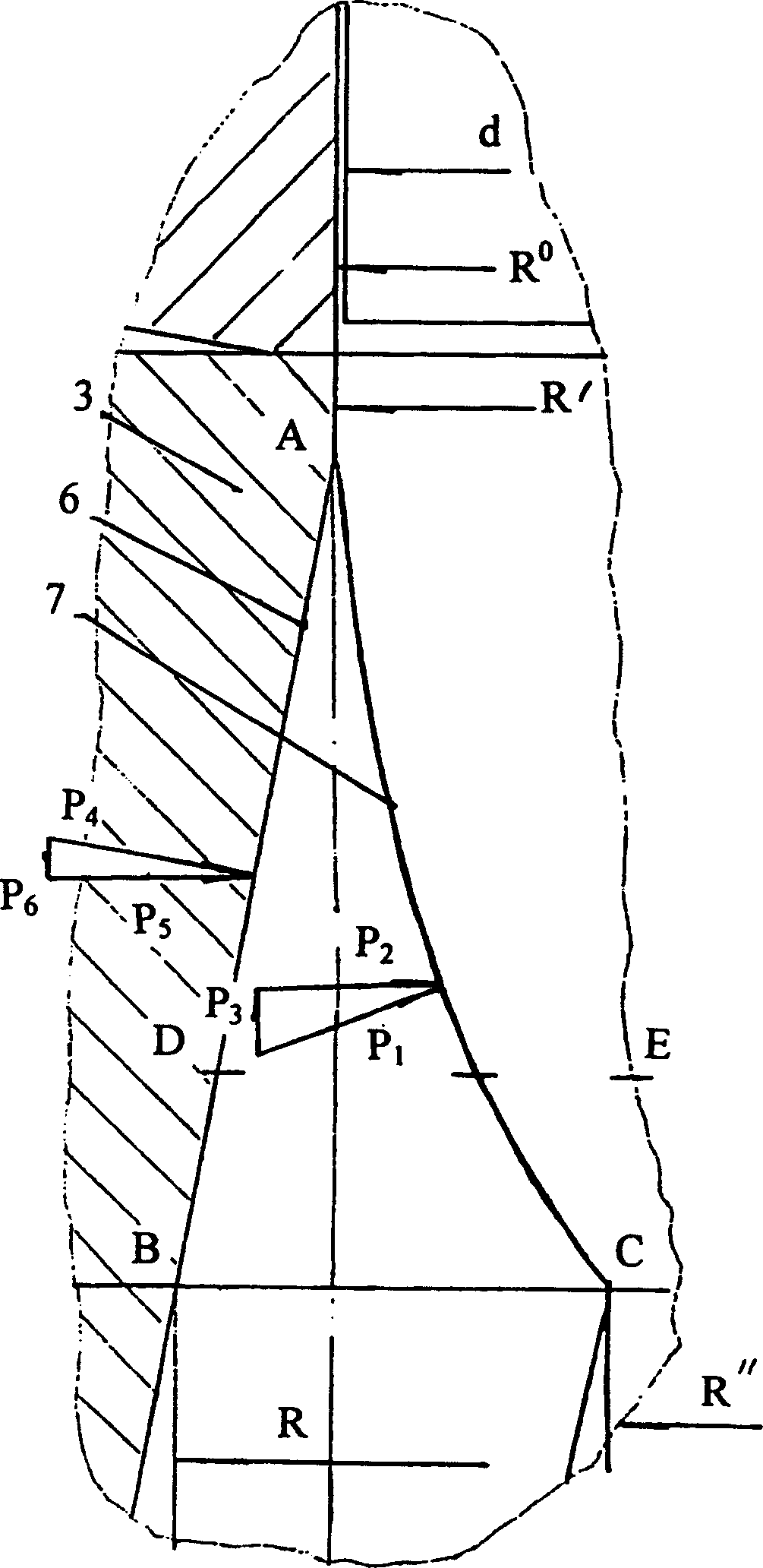

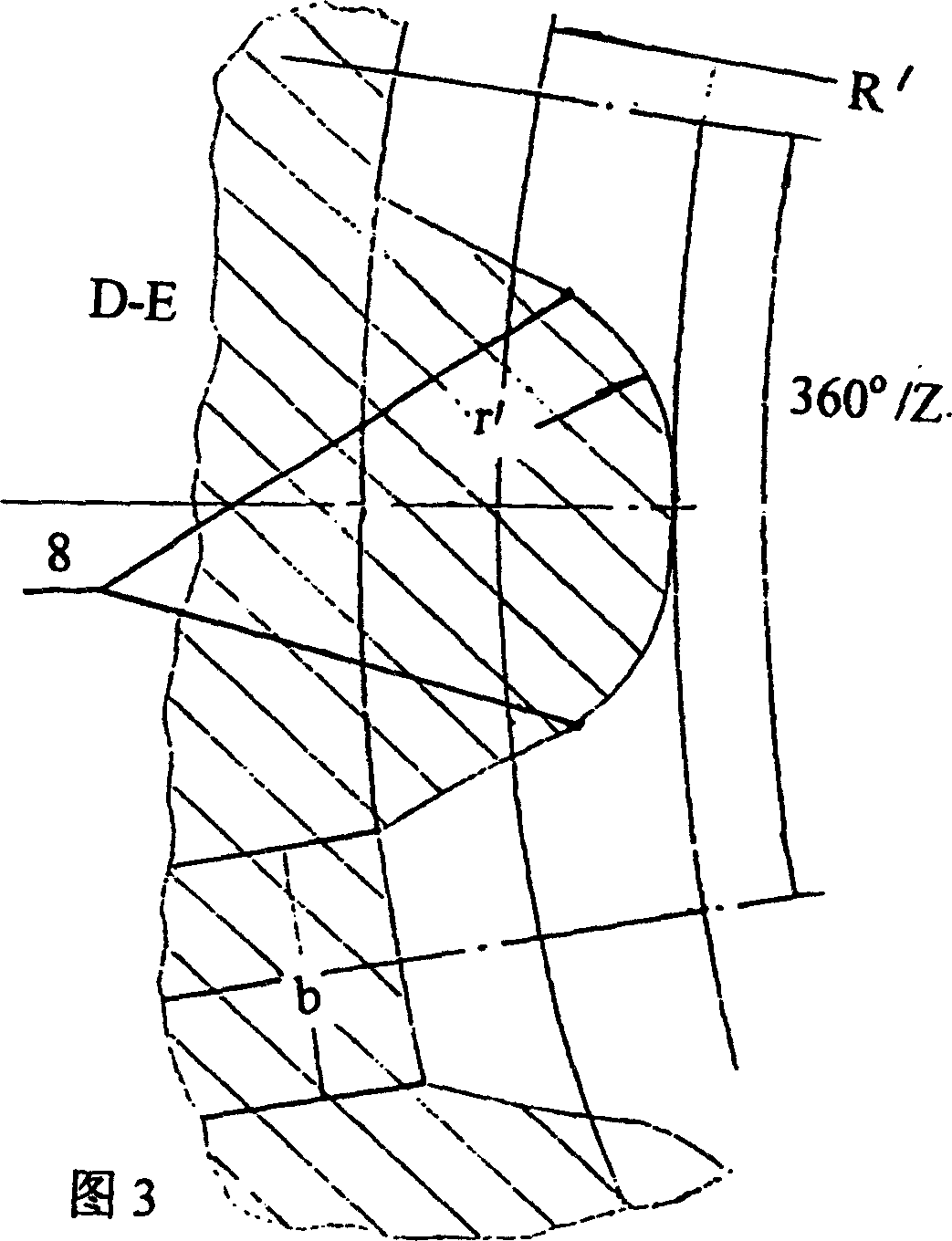

[0021] figure 2 As shown, the end of the die forming section 3 (the B-C section is shown in the figure), the geometric shape and size of the inter-tooth gap are consistent with the tooth profile of the formed gear plane projection. Including the roo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com