A device and method for reducing wrinkling of pipe fittings during compression by using axial electromagnetic tension

An electromagnetic tension, axial technology, applied in the field of metal processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

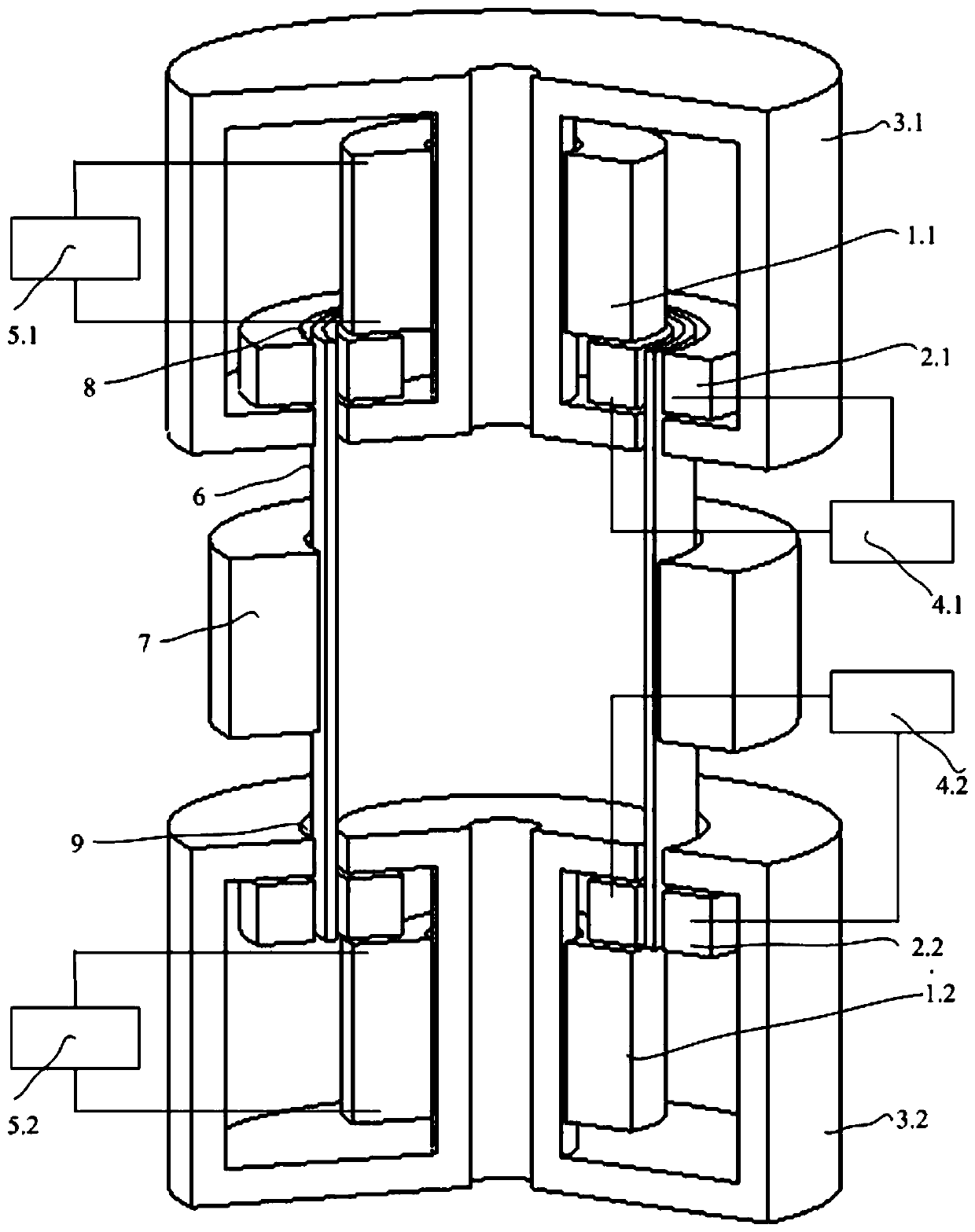

[0041] Such as figure 1 As shown, a device that uses axial electromagnetic tension to reduce wrinkling of pipe fittings during compression, including:

[0042] A pulse force coil 7 for providing forming force to the metal pipe 6 to be formed;

[0043] The first annular yoke 3.1 located at the upper end of the metal pipe to be formed 6, the second annular yoke 3.2 located at the lower end of the metal pipe 6 to be formed;

[0044] The cross section of the first and second ring yokes is a rectangular frame with a gap, the gap of the first ring yoke 3.1 is set in the middle of the lower side of the rectangular frame, and the gap of the second ring yoke 3.2 is set in the rectangular frame The upper middle part of the type; the first and second annular yokes are used to form a constant magnetic field magnetic circuit;

[0045] The cavity of the first annular yoke 3.1 is provided with a first constant magnetic field coil 1.1, and the cavity of the second annular yoke 3.2 is provid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com