Cutting force automatic control main shaft reliability test device and test method

A technology of automatic control device and test device, which is applied in the direction of measuring device, testing of mechanical components, testing of machine/structural components, etc., which can solve problems such as expensive equipment manufacturing costs, inability to accurately simulate the real working conditions of the spindle, and complex control methods , to achieve the effect of verifying the reliability of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0125] The spindle reliability test device and method of the present invention are mainly composed of two parts, namely the spindle reliability test device part and the spindle reliability test method part.

[0126] 1. Spindle reliability test device part

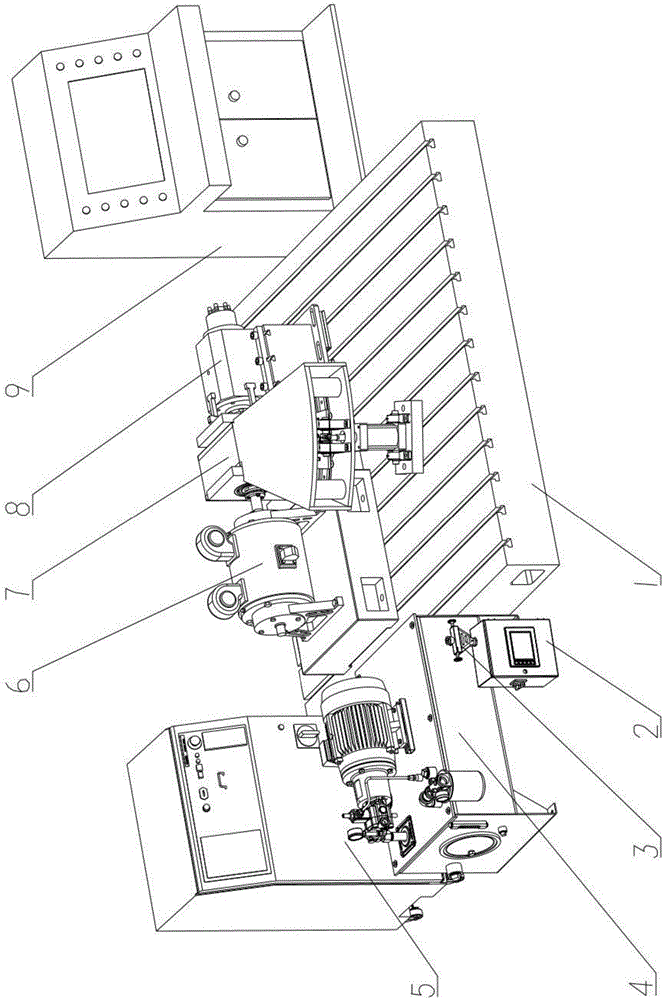

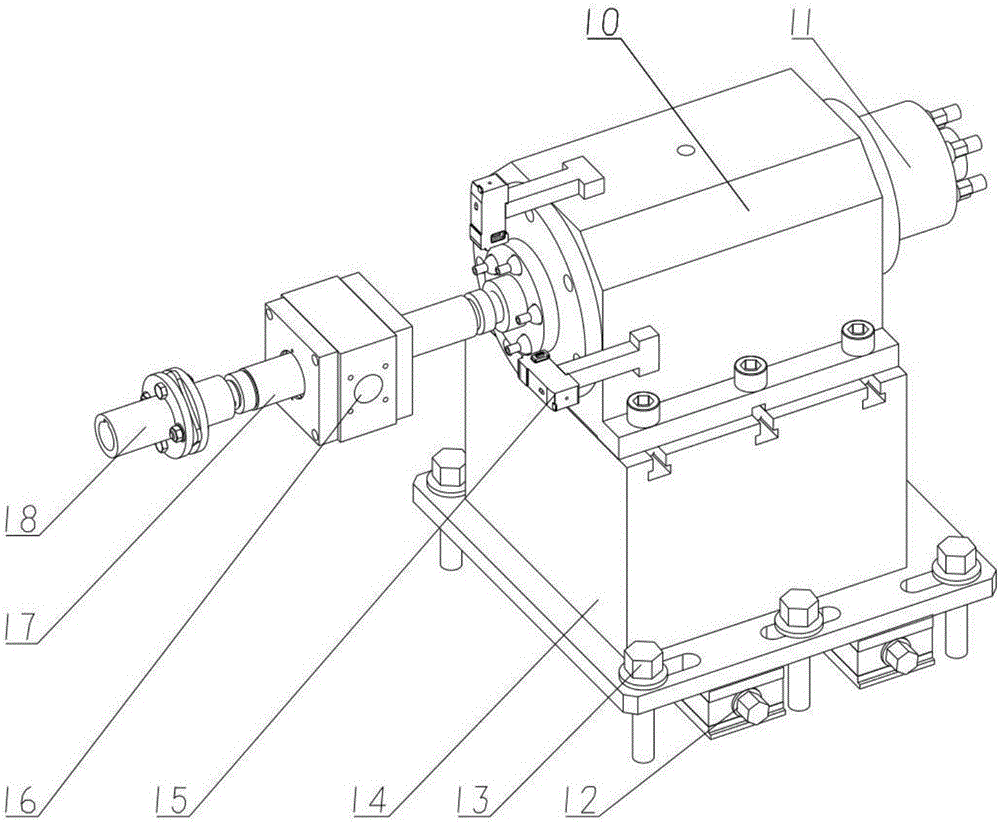

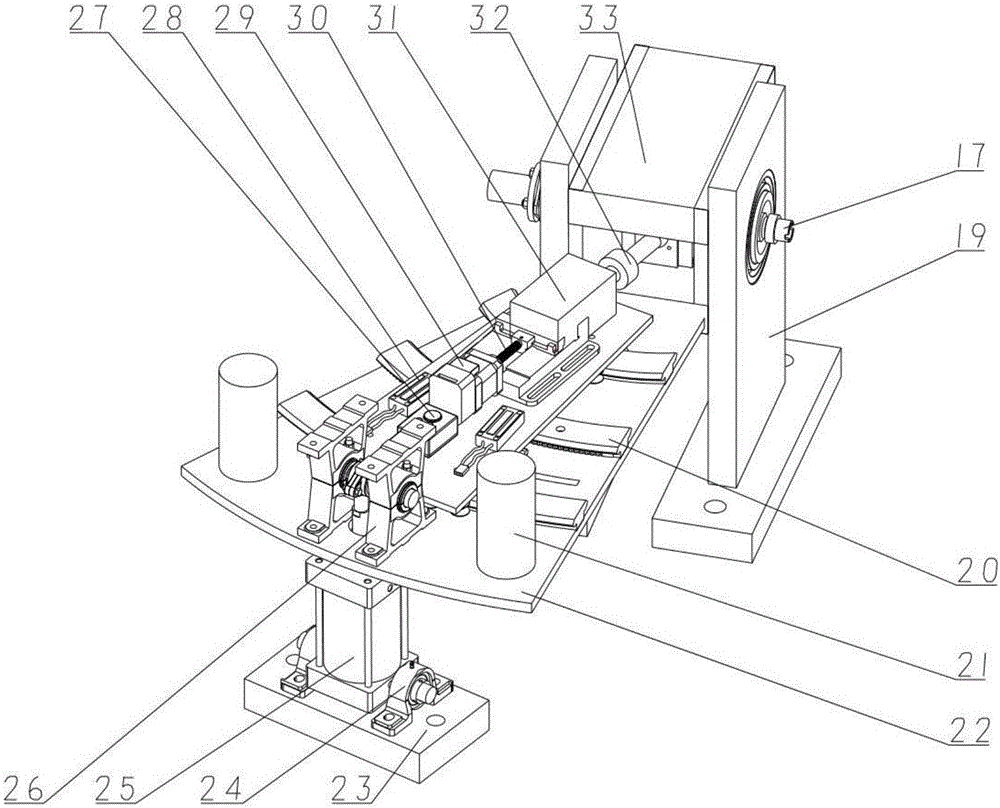

[0127] The spindle reliability test device described in the patent of the present invention is composed of five modules: spindle mounting table 8, cutting force automatic control device 7, cutting torque loading device, state monitoring equipment and auxiliary equipment.

[0128] refer to figure 1 , the composition structure of the spindle reliability test device includes a horizontal iron 1, an oil-air lubrication controller 2, a flow sensor 3, a hydraulic station 4, a cooling control cabinet 5, an electric dynamometer 6, an automatic cutting force control device 7, and a spindle installation Taiwan 8, industrial computer 9. Wherein the electric dynamometer 6, the cutting force automatic control device 7, and the main sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com