Early fault determining method for bearing

A technology of early failure and determination method, which is applied in the direction of mechanical bearing testing, measuring devices, instruments, etc., can solve problems such as difficult to detect early failure of bearings, avoid technical problems of fluctuation changes, improve accuracy, realize extraction and accurate early warning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Preferred embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and are used together with the embodiments of the present invention to explain the principles of the present invention.

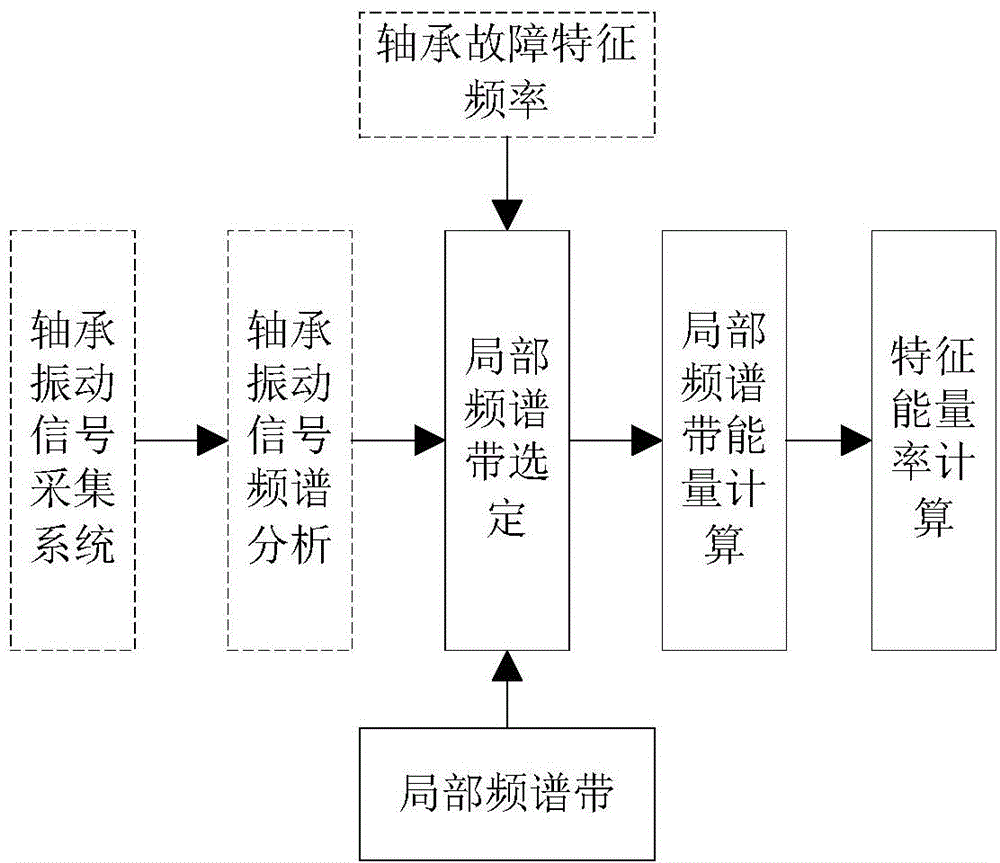

[0051] figure 1 A bearing early fault determination device is shown, which includes a local frequency band determination device, a local frequency band selection device, and a local frequency band energy calculation device.

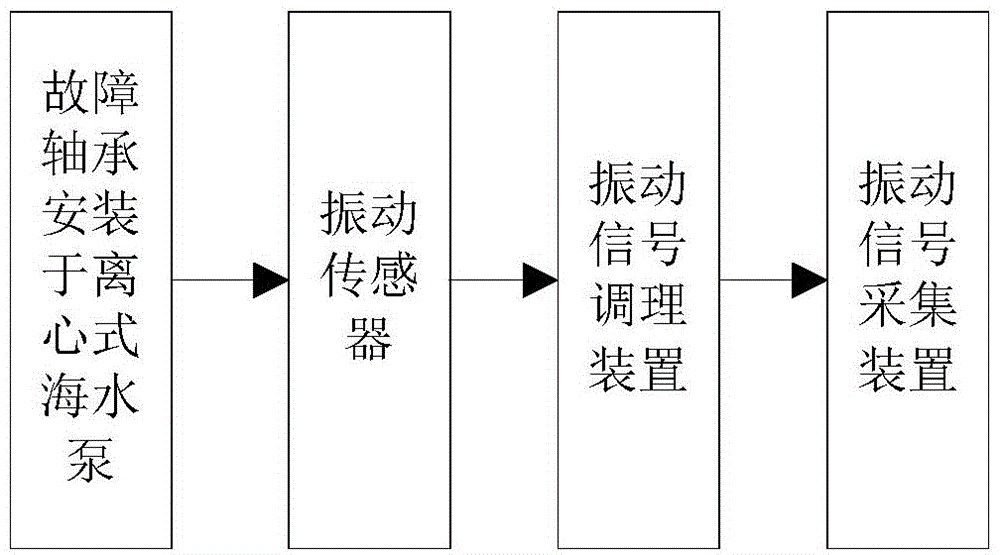

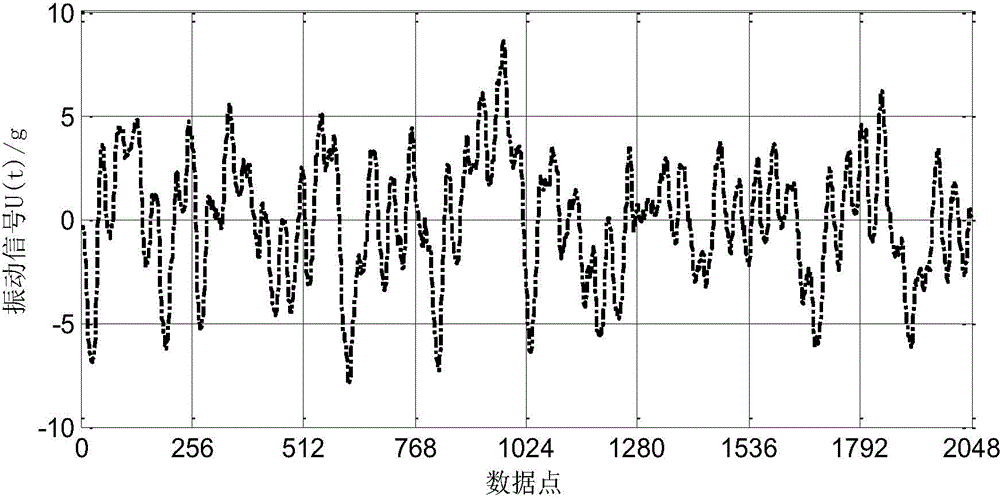

[0052] The bearing early fault determination device is connected with the bearing vibration signal acquisition system through the bearing vibration signal spectrum analysis device. The bearing vibration signal acquisition system is installed in rotating mechanical equipment such as marine centrifugal pumps to obtain vibration signals from bearing parts to form bearing vibration signals. The bearing vibration signal spectrum analy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com