Production process full-period intelligent workshop system based on digital twinning technology and solving method

A production process, full-cycle technology, applied in general control systems, control/regulation systems, program control, etc., can solve problems such as difficult data to guide the physical production line, lack of real-time production data, and inability to consider production lines, so as to reduce the difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the objects, technical solutions, and advantages of the present invention more clear, the technical solutions in the embodiments in the embodiments of the present invention will be described in contemplation in conjunction with the embodiments and drawings of the present invention.

[0040] The present invention provides a digital twin-oriented, digitally-oriented, intelligent production process, full-cycle smart workshop system, realizing the design plan for the full life cycle of the production line, the mid-flexible synchronization and the later feedback control, thereby improving the production line The operational efficiency reduces safety accidents and economic losses due to equipment failures.

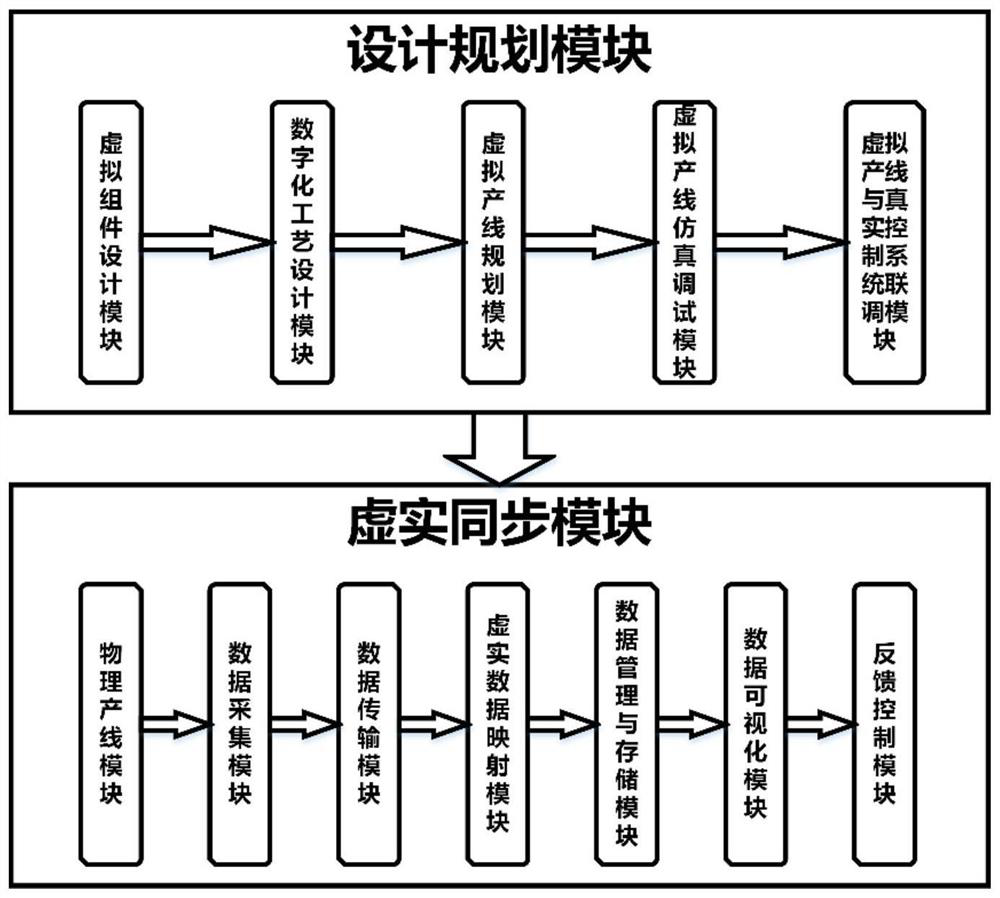

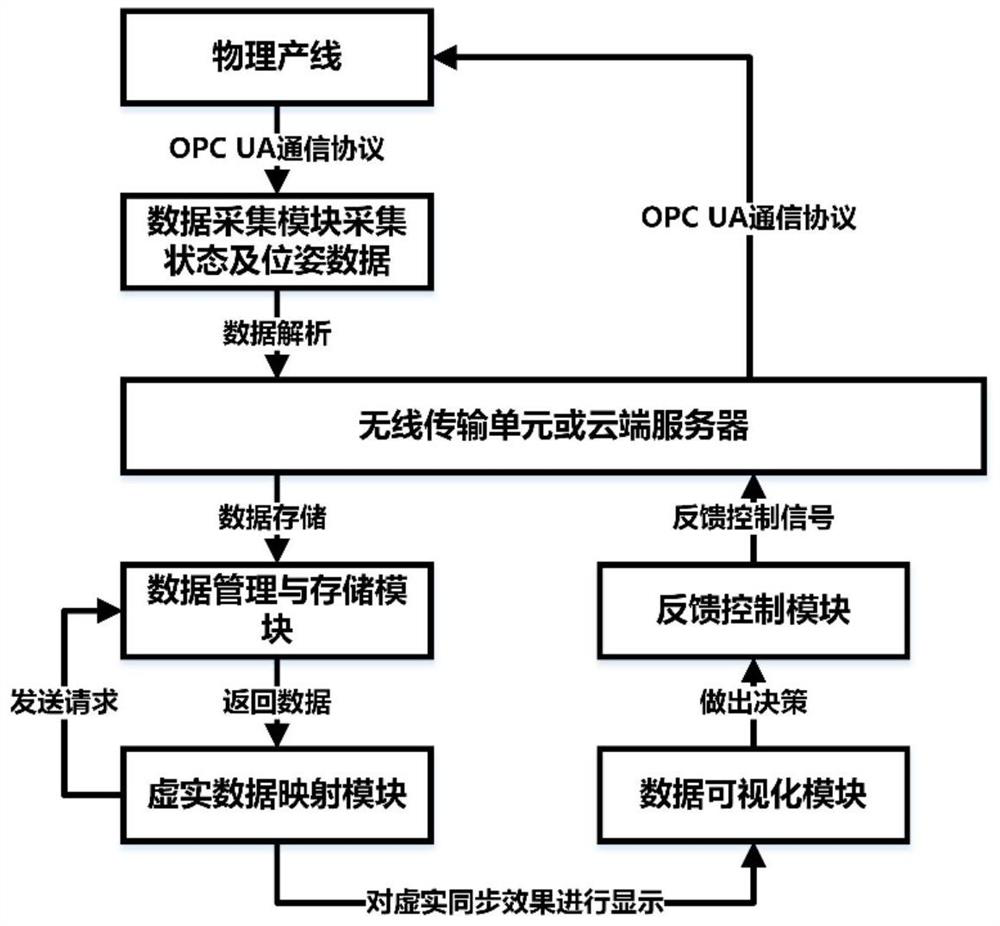

[0041] A full cycle smart workshop system based on digital twin technology, which mainly includes two major modules: design planning module and virtual real synchronization module.

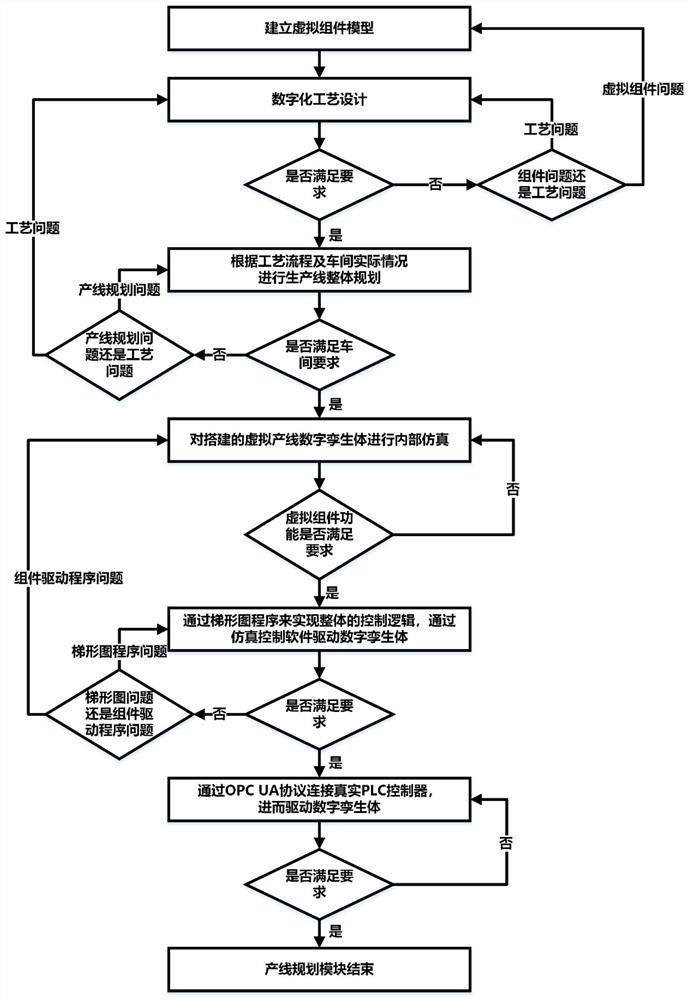

[0042] The design planning module, first designing the virtual components re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com