Method for detecting contact pressure between conductive slip ring and conductive brush wire

A contact pressure, conductive slip ring technology, applied in force/torque/work measuring instruments, measuring devices, instruments, etc., can solve the problems of not finding, not collecting data, detecting the contact pressure of conductive slip ring brush wire, etc. Reliable Intuitive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

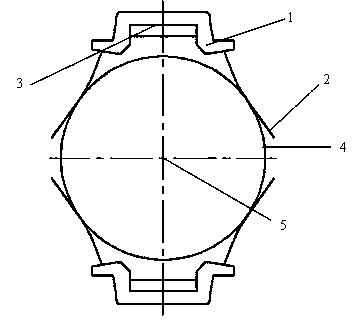

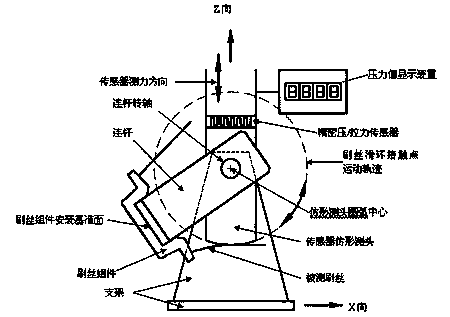

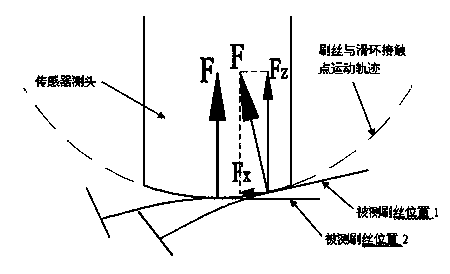

[0018] The working principle of the conductive slip ring-brush combination is shown in figure 1 The brush wire 2 is installed on the brush wire assembly 1, which is fixed on the brush wire assembly installation reference surface 3 of the outer cylinder of the slip ring assembly; the conductive slip ring 4 is installed in the center of the outer cylinder through a bearing, and can rotate around the center of rotation of the slip ring. There is a certain deflection when the brush wire is in contact with the conductive slip ring, so that there is a contact pressure between the brush wire and the conductive slip ring and conducts electricity. The brush wire is connected with the electric circuit of the fixed equipment, and the conductive slip ring is connected with the electric circuit of the rotating equipment, so as to realize the continuous electric transmission from the fixed equipment to the rotating equipment.

[0019] Here, the specific implementation of this patent will be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com