Control method for solving scheduling of operating workshops under complex production environment based on improved genetic algorithm

An improved genetic algorithm and job shop technology, applied in the field of job shop scheduling control, can solve problems such as poor practicability, poor reliability, and poor accuracy of job shop scheduling technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be further described below in conjunction with the accompanying drawings.

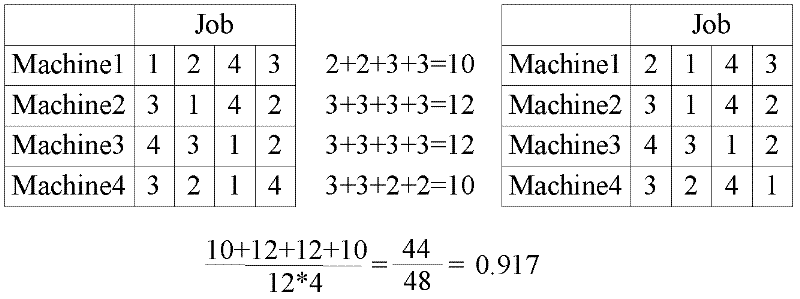

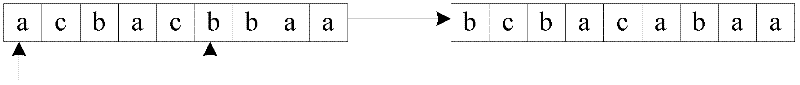

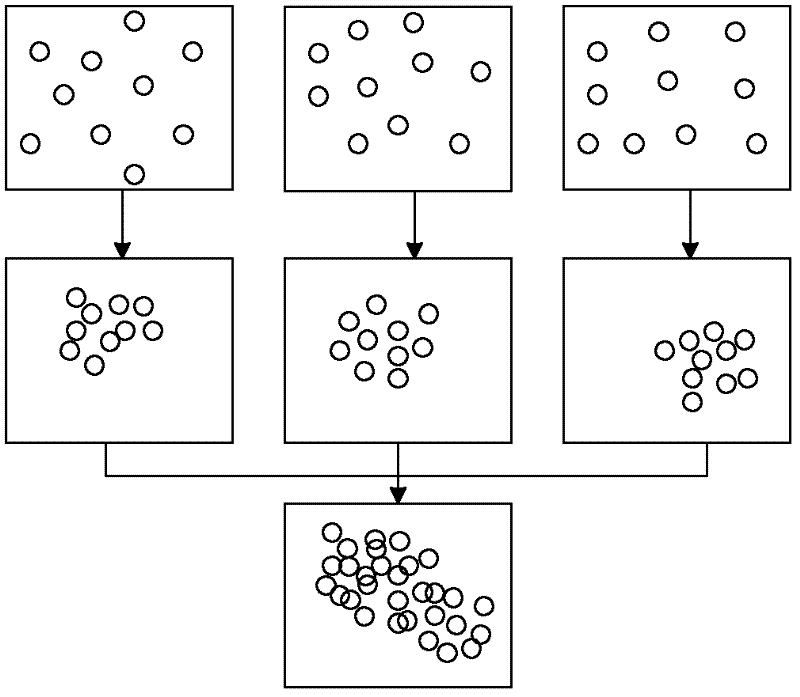

[0073] refer to Figure 1 to Figure 4 , a method based on an improved genetic algorithm to solve the job shop scheduling control method in a complex production environment, the control method includes the following steps:

[0074] 1. Determine the objective function of fuzzy parameter job shop scheduling

[0075] In order to more closely reflect the situation that job shop scheduling maximizes customer satisfaction and customers have different satisfaction levels for different products, a job shop scheduling model with fuzzy parameters is proposed to maximize all product satisfaction and maximize minimum satisfaction as The objective function is

[0076] z 1 = Σ i = 1 n w i AI ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com