Lithium ion battery cathode material pulp and preparation method thereof

A lithium-ion battery and negative electrode material technology, applied in the direction of electrode manufacturing, battery electrodes, secondary batteries, etc., can solve the problems of long time for slurry preparation, affecting the performance of making batteries, and low efficiency of equipment use, so as to improve the two Sub-agglomeration phenomenon, overcoming the formation of negative electrode slurry particles, and improving the effect of equipment utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

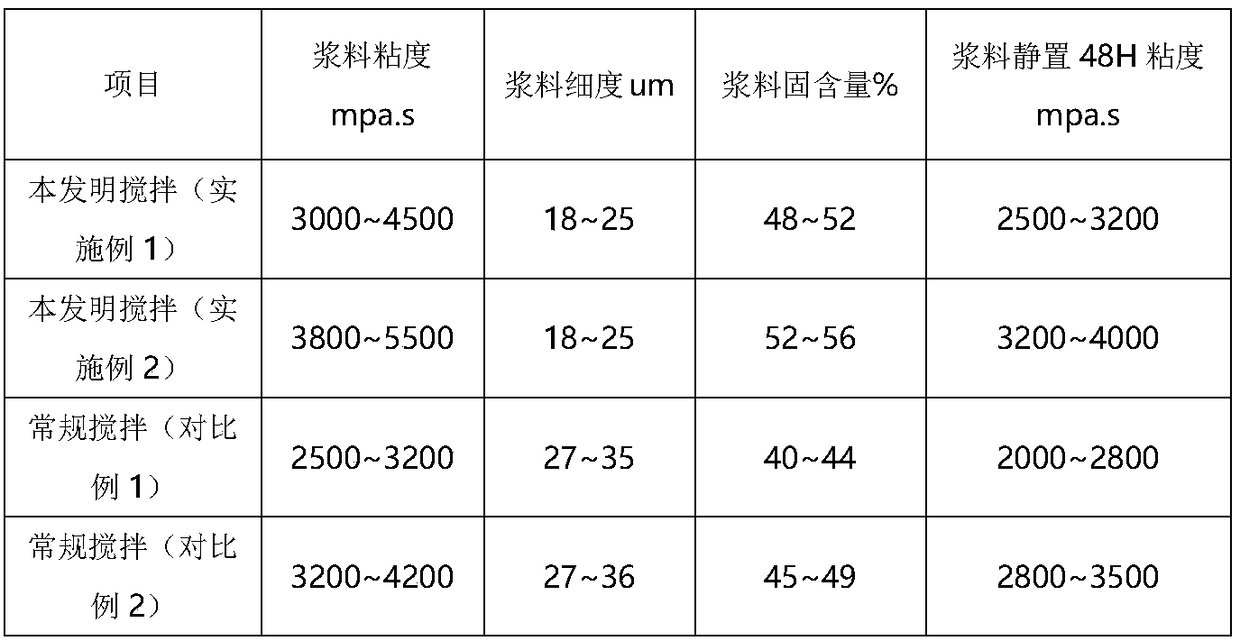

Embodiment 1

[0031] Use 30L double planetary stirring (high kneading stirring, the highest stirring parameters: stirring 25 rpm; dispersing 2100 rpm).

[0032] Negative electrode material formula (relative to negative electrode active material mass proportion): artificial graphite: 90.5%, conductive carbon black: 3.8%, CMC (sodium carboxymethyl cellulose): 2.2%, SBR (styrene-butadiene rubber): 3.5%, deionized Water: 100%.

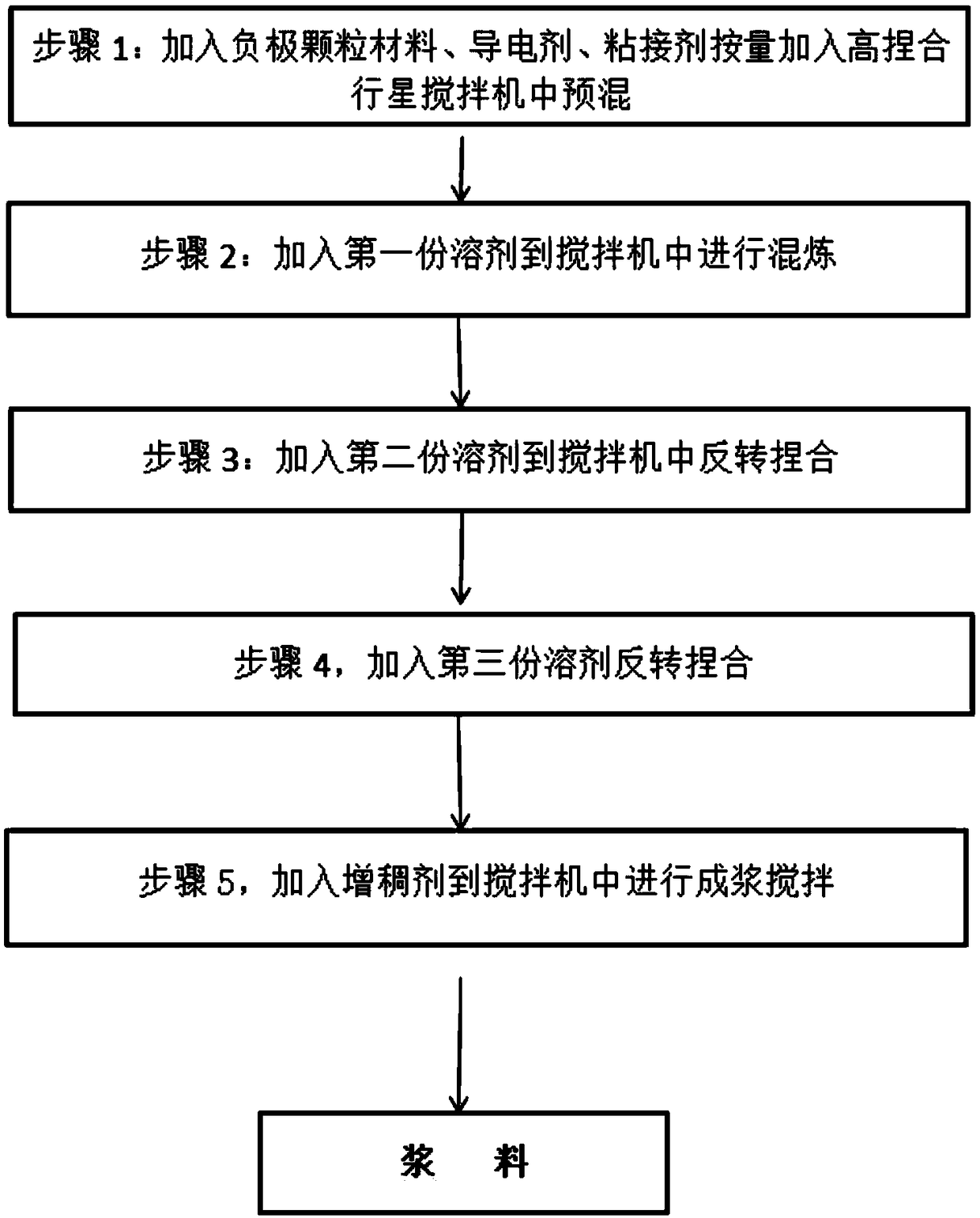

[0033] Such as figure 1 As shown, the negative electrode material preparation steps are as follows:

[0034] Step 1: Add artificial graphite, conductive carbon black, and CMC into the mixer for pre-mixing for 10 minutes. Stirring method: forward rotation, stirring speed revolution: 10r / min, dispersion: 0 rpm;

[0035] Step 2: Add deionized water equivalent to 30% of the total amount of negative electrode active materials into the mixer for initial mixing and stirring for 20 minutes. When stirring, set the temperature at 30°C to 40°C, and cool it with cooling water whe...

Embodiment 2

[0041] Use 30L double planetary stirring (high kneading stirring, the highest stirring parameters: stirring 25 rpm; dispersing 2100 rpm).

[0042] Negative electrode formula: artificial graphite: 97%, conductive agent 1%, CMC (sodium carboxymethyl cellulose): 1.0%, SBR (styrene-butadiene rubber): 1.0%; deionized water: 90%

[0043] Step 1: Add artificial graphite, conductive agent, and CMC into the mixer and pre-mix for 10 minutes. Stirring method: forward rotation, stirring speed revolution: 6r / min, dispersion: 0 rpm;

[0044] Step 2: Add 35% deionized water into the mixer for initial mixing and stirring for 20 minutes. When stirring, set the temperature at 30°C to 40°C, and cool down with cooling water when the temperature exceeds 40°C. Stirring method: forward rotation, stirring speed revolution: 15r / min, dispersion: 0 turns;

[0045]Step 3: Add 30% deionized water into the blender and stir for 30 minutes. When stirring, set the temperature at 30°C to 40°C. If the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com