Apparatus for performing binding processing on sheets and post-processing apparatus provided with the same

A post-processing device and technology of processing device, which are applied in thin material processing, stack receiving device, transportation and packaging, etc., can solve problems such as sheet falling off, achieve the effect of simple structure and avoid cluttered posture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

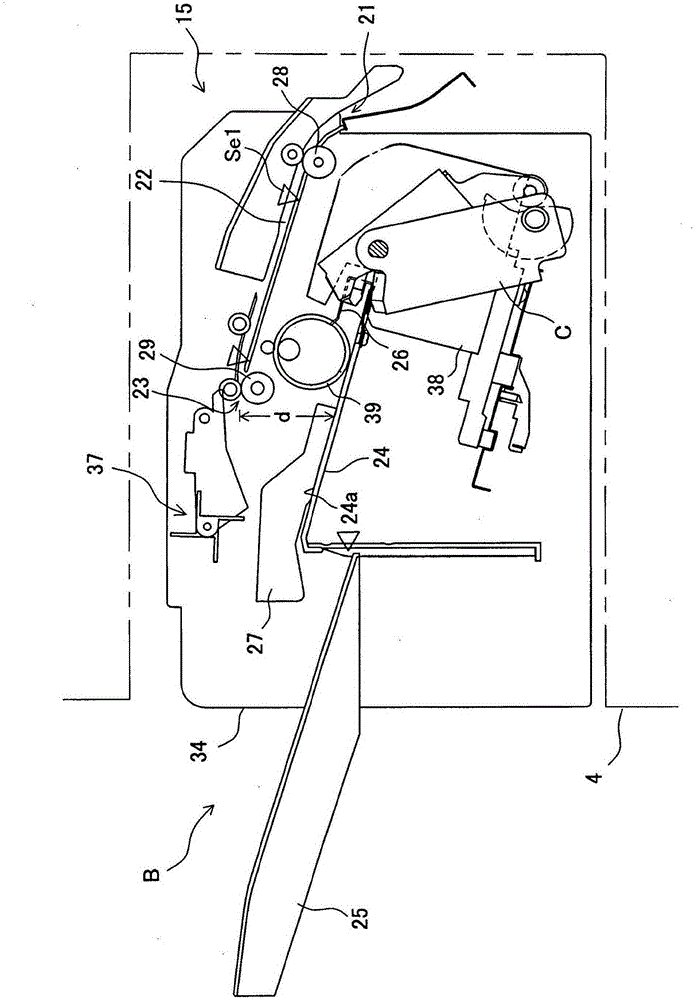

[0175] refer to Figure 6 The first embodiment will be described. In the aforementioned post-processing apparatus B, when stacking sheets on the processing tray 24, a positioning reference (Sp) for positioning the sheets at a predetermined processing position (staple position) P is provided, and a stapling processing mechanism is arranged. 49 so that the binding process is performed on the sheets positioned on the reference.

[0176] In the illustrated first embodiment, the above-mentioned positioning reference Sp is configured to be able to select the sheet regulating position of the sheet end regulating member 26 between the standard 1 ( Sp1 ) and the standard 2 ( Sp2 ).

[0177] Therefore, as shown in (d) of the figure, the sheet end restricting member (collision stopper) 26 is supported by the bottom of the processing tray 24 so as to be movable (slidable) in the sheet feeding direction (vertical direction in the figure).

[0178] The sheet end regulating member 26 is co...

no. 2 approach

[0189] right Figure 7 The second embodiment shown will be described. The structure in this figure shows the case where the regulating mechanism for positioning the sheet on the processing tray 24 is set so that "the pair of left and right side edge regulating members 27 can be moved between the first reference Cp1 and the second reference Cp2". .

[0190] A case where the sheet is positioned at the processing position on the basis of the illustrated center will be described. A pair of left and right side edge restricting members 27 are supported by the processing tray 24 so as to be movable in the width direction. In the illustrated structure, each side edge restricting member 27a, 27b is slidably fitted into a guide groove (not shown) arranged on the bottom surface of the processing tray 24 .

[0191] An alignment motor M1 (a pair of left and right drive motors in the illustrated configuration) and a transmission mechanism 56 (a rack-and-pinion mechanism, a pulley mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com