Method for preparing liquid plasticine and plasticine molding method

A technology of liquid plasticine and sol, applied in toys, entertainment, etc., can solve the problems of difficult, time-consuming and labor-intensive fine control of the structure, and achieve the effect of simple shape control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

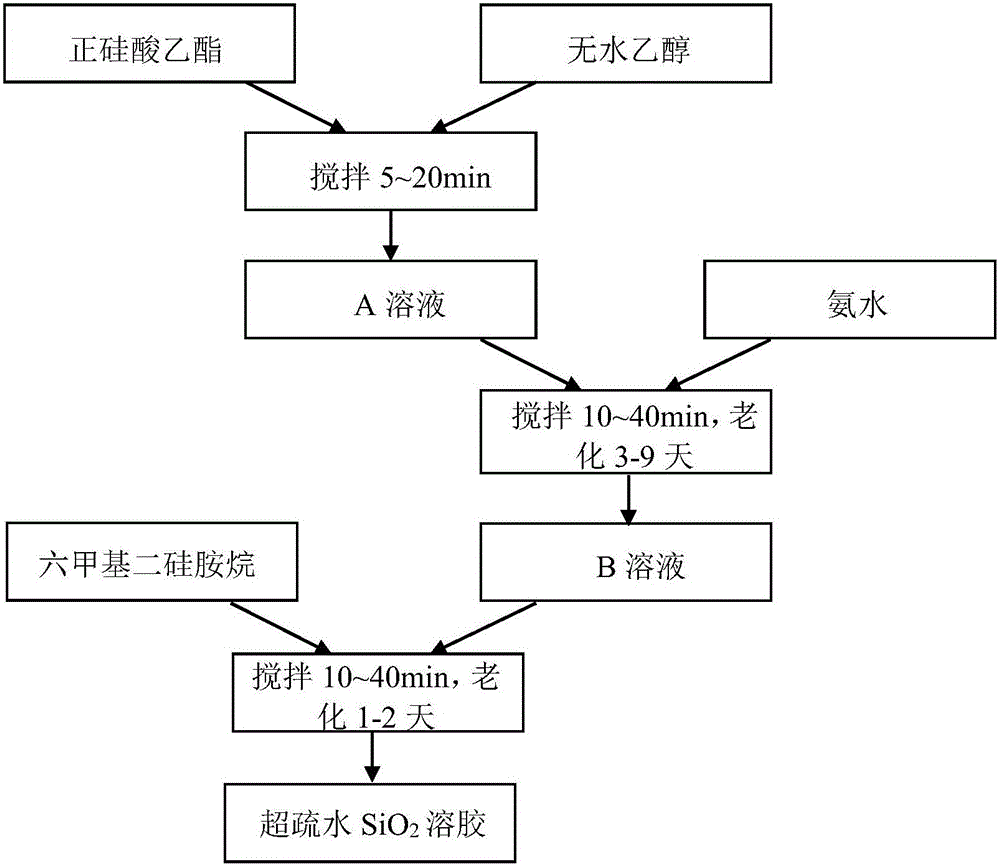

[0030] 1. Measure 150ml of absolute ethanol (EtOH) and 9-21ml of tetraethyl orthosilicate (TEOS) into a beaker, stir at room temperature for 5-20min to mix evenly; then add 3.9-6.9ml to a concentration of 25 % of ammonia (NH 3 ·H 2 O) Stirring for 10-40min, then standing and aging at room temperature for 3-9 days; immersing the slide glass in the sol, pulling the slide glass through the pulling coating method at a speed of 4000 μm / s, when the sol can be placed on the slide glass When the film is uniformly formed on the chip and the film is thick (film thickness is 150-350nm), you can add 2.16-16.56ml of hexamethyldisilazane (HMDS) and stir for 10-40min, then let it stand for aging for 1-2 days , that is, to obtain the alkylated SiO 2 Sol. The whole preparation process was sealed to the sol to avoid the evaporation of absolute ethanol.

[0031] Wherein the volume ratio of added reagent is:

[0032] TEOS:EtOH:NH 3 ·H 2 O:HMDS=(3~7):50:(1.3~2.3):(0.72~5.52).

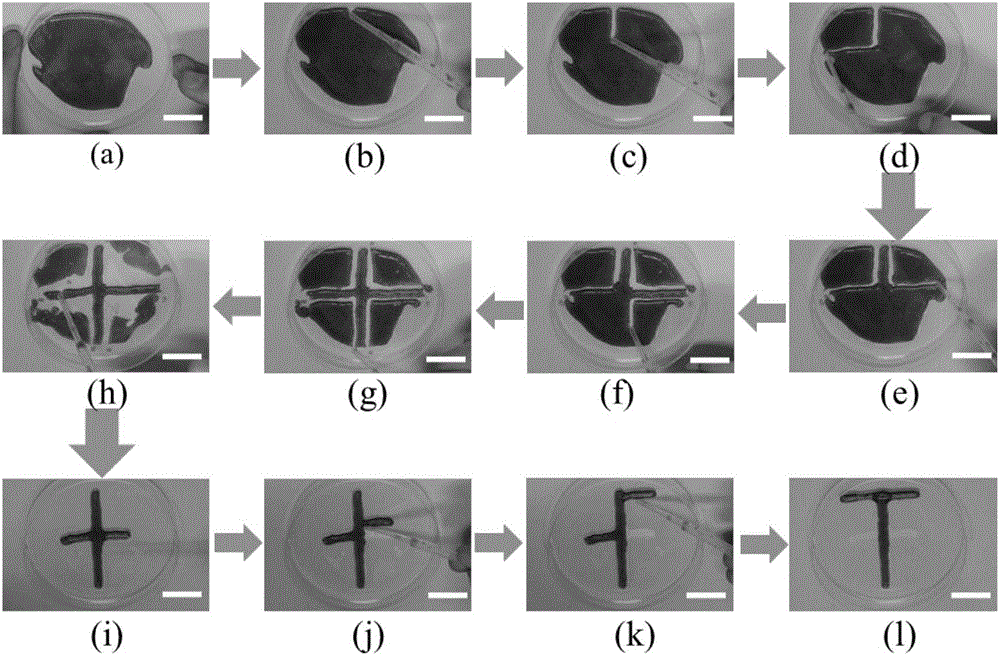

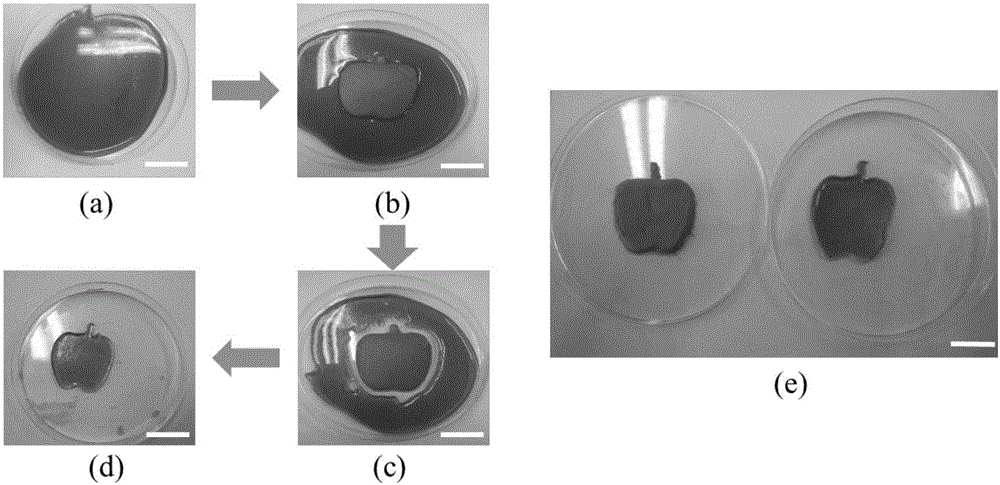

[0033] 2. T...

Embodiment 2

[0037] 1. Measure 150ml of absolute ethanol (EtOH) and 9-21ml of tetraethyl orthosilicate (TEOS) into a beaker, stir at room temperature for 5-20min to mix evenly; then add 3.9-6.9ml to a concentration of 25 % of ammonia (NH 3 ·H 2 O) Stirring for 10-40min, then standing and aging at room temperature for 3-9 days; immersing the slide glass in the sol, pulling the slide glass through the pulling coating method at a speed of 4000 μm / s, when the sol can be placed on the slide glass When the film is uniformly formed on the chip and the film is thick (film thickness is 150-350nm), you can add 2.16-16.56ml of hexamethyldisilazane (HMDS) and stir for 10-40min, then let it stand for aging for 1-2 days , that is, to obtain the alkylated SiO 2Sol. The whole preparation process was sealed to the sol to avoid the evaporation of absolute ethanol.

[0038] Wherein the volume ratio of added reagent is:

[0039] TEOS:EtOH:NH 3 ·H 2 O:HMDS=(3~7):50:(1.3~2.3):(0.72~5.52).

[0040] 2. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com