A class of fullerene-calixarene host-guest composite nanocrystalline material and preparation method thereof

A nanocrystalline material, fullerene-like technology, applied in the field of preparation of fullerene host-guest composite nanocrystalline materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

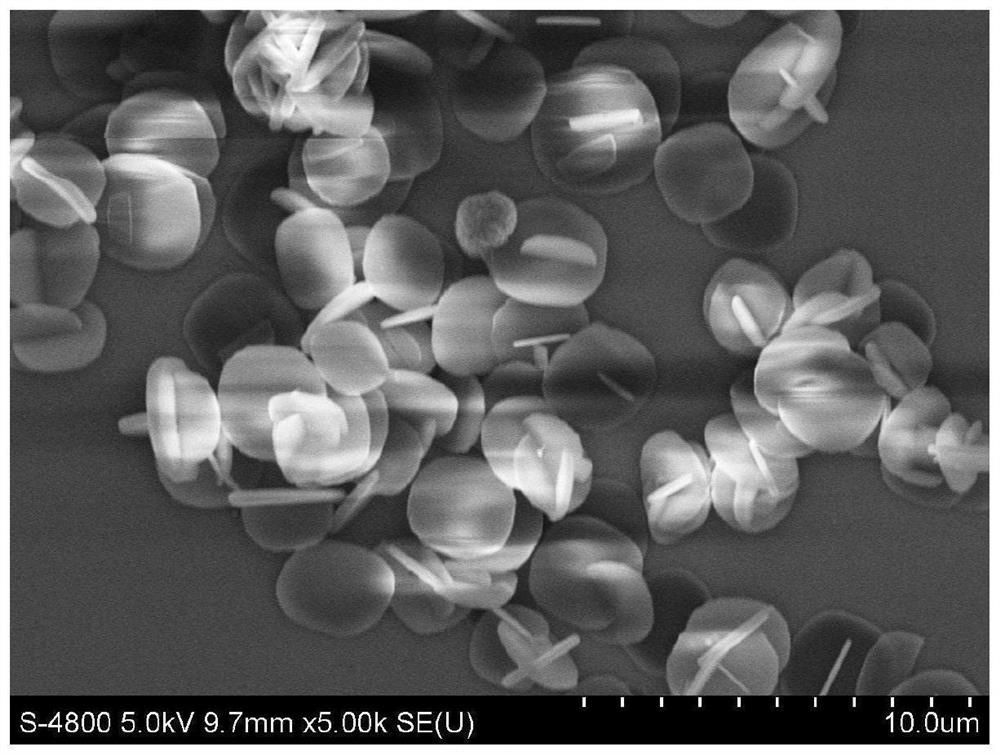

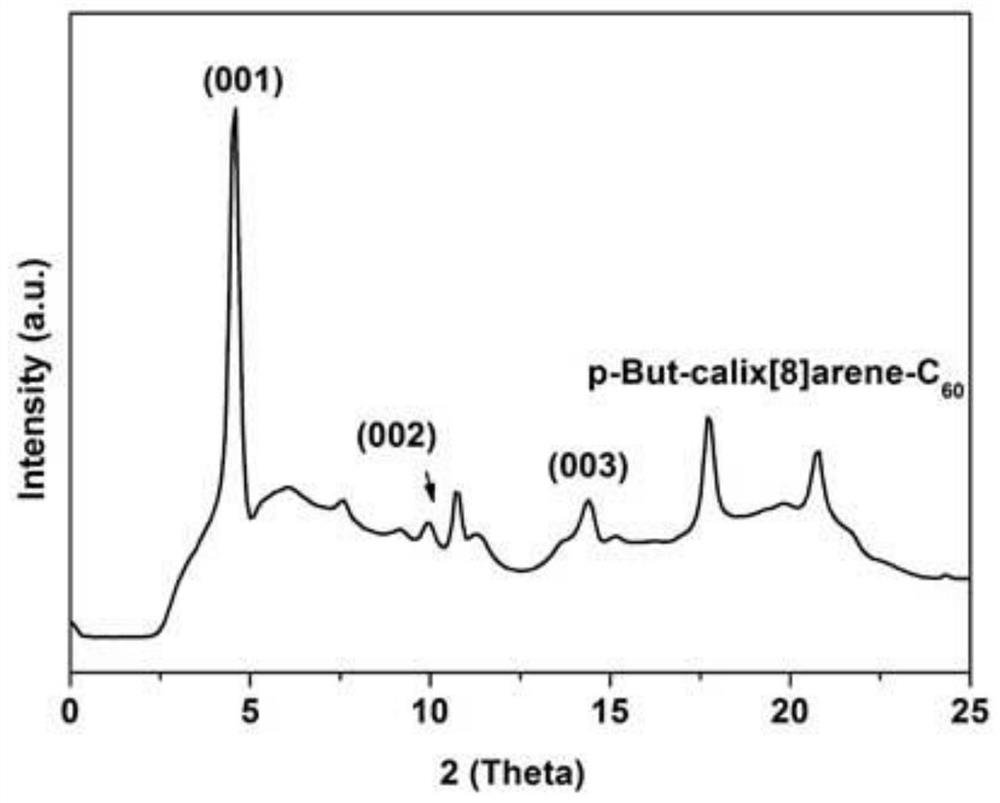

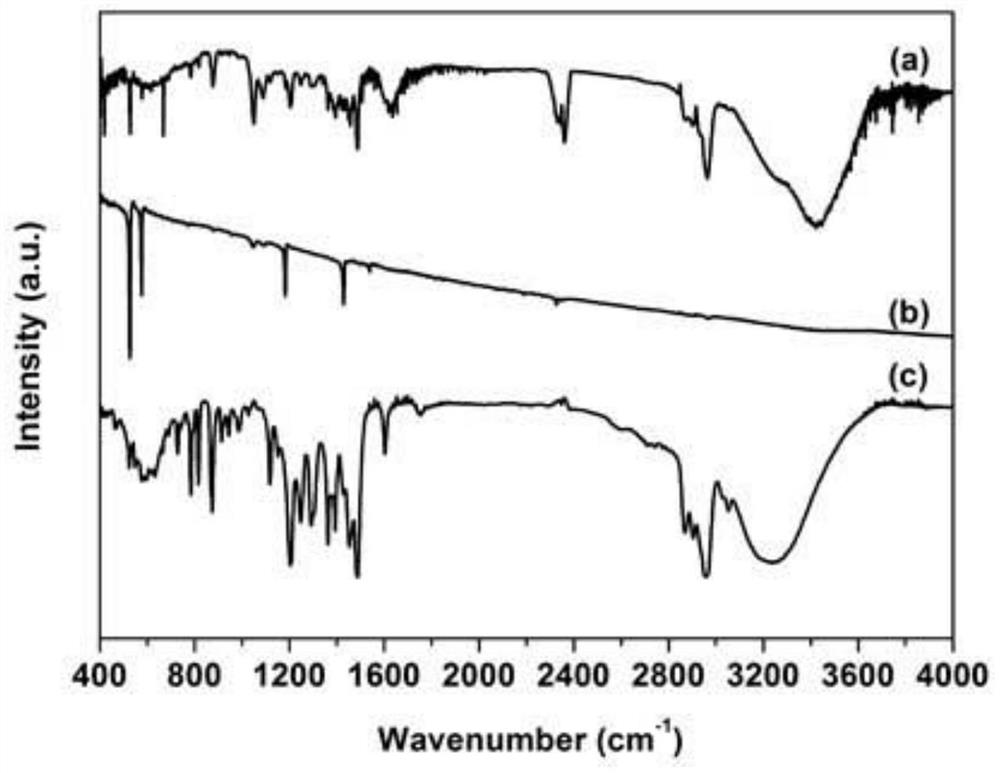

Embodiment 1

[0030] S1. The excess C 60 Put the powder into benzene and sonicate for 1-2 minutes, then let the solution stand at room temperature for 2-5 hours, and let the excess C 60 After complete precipitation, remove the upper layer solution, this solution is saturated C 60 Benzene solution;

[0031] S2. Put excess p-tert-butylcalix[8]arene powder into benzene and ultrasonically for 1-2 minutes, then let the solution stand at room temperature for 2-5 hours, until the excess p-tert-butylcalix[8] After the aromatic hydrocarbons are completely precipitated, the upper layer solution is removed, and this solution is a saturated p-tert-butylcalix[8]arene benzene solution;

[0032] S3. Use a pipette to saturate the above configured C 60 Benzene solution and saturated p-tert-butylcalix[8]arene benzene solution are mixed at a volume ratio of 1:1, and ultrasonicated for 1-2 minutes;

[0033] S4. add isopropanol to above-mentioned mixed solution as precipitating agent, add isopropanol volume...

Embodiment 2

[0037] S1. The excess C 60 Put the powder into toluene and sonicate for 1-2 minutes, then let the solution stand at room temperature for 2-5 hours, until the excess C 60 After complete precipitation, remove the upper layer solution, this solution is saturated C 60 Toluene solution;

[0038] S2. Put the excess p-tert-butylcalix[8]arene powder into toluene and ultrasonicate for 1-2 minutes, then let the solution stand at room temperature for 2-5 hours, until the excess p-tert-butylcalix[8] After the aromatic hydrocarbons are completely precipitated, the upper layer solution is removed, and this solution is a saturated p-tert-butylcalix[8]arene toluene solution;

[0039] S3. Use a pipette to saturate the above configured C 60 Toluene solution and saturated p-tert-butylcalix[8]arene toluene solution were mixed at a volume ratio of 1:1, and ultrasonicated for 1-2 minutes;

[0040] S4. add isopropanol to above-mentioned mixed solution as precipitating agent, add isopropanol volu...

Embodiment 3

[0044] S1. The excess C 70 Put the powder into benzene and sonicate for 1-2 minutes, then let the solution stand at room temperature for 2-5 hours, and let the excess C 70 After complete precipitation, remove the upper layer solution, this solution is saturated C 70 Benzene solution;

[0045] S2. Put excess p-tert-butylcalix[8]arene powder into benzene and ultrasonically for 1-2 minutes, then let the solution stand at room temperature for 2-5 hours, until the excess p-tert-butylcalix[8] After the aromatic hydrocarbons are completely precipitated, the upper layer solution is removed, and this solution is a saturated p-tert-butylcalix[8]arene benzene solution;

[0046] S3. Use a pipette to saturate the above configured C 70 Benzene solution and p-tert-butylcalix[8]arene benzene solution are mixed at a volume ratio of 1:1, and ultrasonicated for 1-2 minutes;

[0047] S4. Add isopropanol to the above mixed solution with a pipette as a precipitating agent, and the volume of add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com