Silver nanowire modified polyacrylate conductive composite coating and preparation method thereof

A polyacrylate, silver nanowire technology, applied in conductive coatings, nanotechnology, nanotechnology and other directions, can solve the problem of weak bonding force between silver nanowires and substrates, difficult uniform dispersion of silver nanowires, affecting the comprehensive performance of composite coatings, etc. problems, to achieve the effect of easy control of coating morphology, excellent mechanical and electrical properties, and low substrate requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

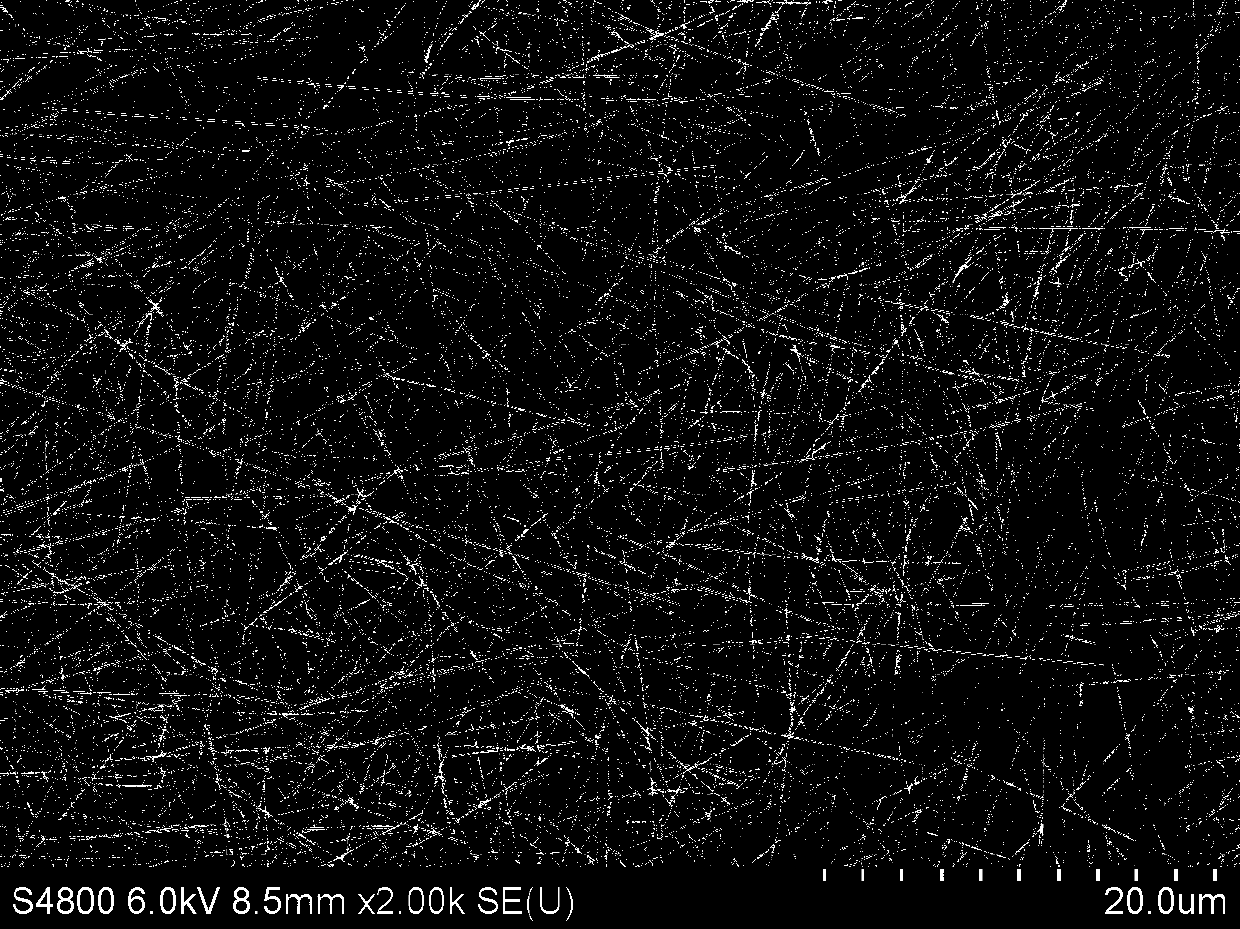

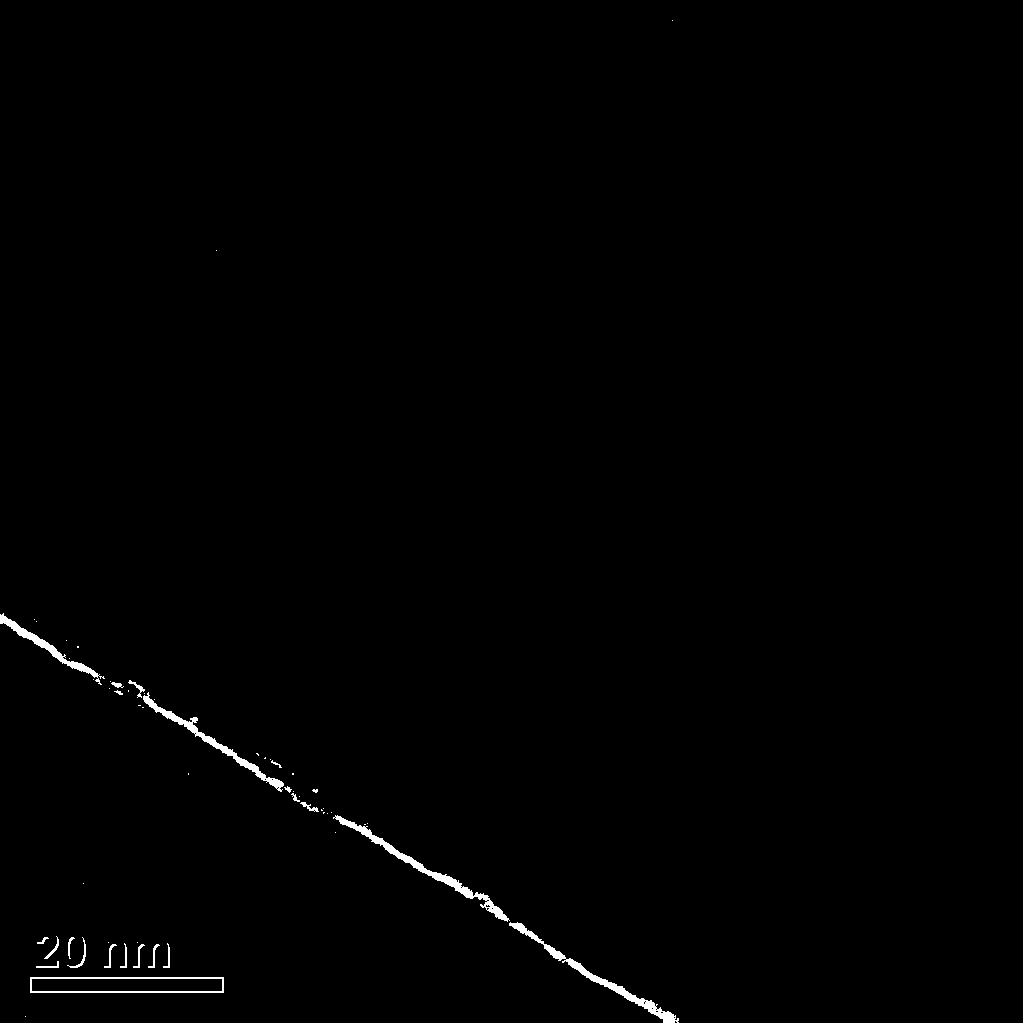

[0037] (1) Add 10mL of ethylene glycol into a round-bottom three-neck flask, reflux at 180°C for 1h, then stabilize the temperature at 180°C, and then add 5mL of ethylene glycol solution containing perchloroplatinic acid with a concentration of 0.06mM As a seed crystal, after heating for 10 minutes, add 5 mL of 0.1 mM silver nitrate-containing ethylene glycol solution and 70 mL of 0.08 wt% polyacrylamide-containing ethylene glycol solution at the same time. The molecular weight of polyacrylamide is 160 Wan (AP~273, The Dow Chemical Company), control the dropping speed of the two so that the dropping time is 1h, continue to react for 1.5h after the dropping, stop heating to obtain a solution containing silver nanowires, the silver nanowires The diameter is 80~100nm, and the length is 20~30μm. A stirrer was used throughout the reaction with a stirring speed of 300 rpm. attached figure 1 The morphology of silver nanowires is shown. attached figure 2 It shows that the surface...

Embodiment 2

[0041] (1) Add 5mL of ethylene glycol into a round bottom three-neck flask, reflux at 120°C for 4h, then adjust the temperature and stabilize it to 190°C, then add 10mL of ethylene glycol containing perchloroplatinic acid with a concentration of 0.01mM The solution was used as a seed crystal, and after heating for 1 minute, 0.5mL of 0.9mM silver nitrate-containing ethylene glycol solution and 100mL of 0.05wt% polyacrylamide-containing ethylene glycol solution were added simultaneously. The molecular weight of polyacrylamide 1.6 million (AP ~ 273, The Dow Chemical Company), the addition rate of the two is controlled so that the addition time is 0.5h, after the end of the addition, the reaction is continued for 4h and then the heating is stopped to obtain a solution containing silver nanowires. The diameter of the nanowire is 80-100 nm, and the length is 20-35 μm. A stirrer was used throughout the reaction with a stirring speed of 100 rpm.

[0042] (2) Let the silver nanowire s...

Embodiment 3

[0045] (1) Add 30mL of ethylene glycol into a round-bottom three-neck flask, reflux at 200°C for 0.5h, then adjust the temperature and stabilize it to 150°C, then add 2mL of ethylene glycol containing perchlorplatinic acid with a concentration of 0.1mM Alcohol solution is used as crystal seed, after heating for 60 minutes, then add 10mL concentration of 0.01mM ethylene glycol solution containing silver nitrate and 50mL concentration of 0.1wt% ethylene glycol solution containing polyacrylamide at the same time, the molecular weight of polyacrylamide 1.6 million (AP ~ 273, The Dow Chemical Company), the addition rate of the two is controlled so that the addition time is 2h, after the end of the addition, the reaction is continued for 0.5h and then the heating is stopped to obtain a solution containing silver nanowires. The diameter of the nanowire is 60~80nm, and the length is 10~13μm. A stirrer was used throughout the reaction with a stirring speed of 900 rpm.

[0046] (2) Let...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com