Method for producing aluminium oxide ceramic ball

A kind of technology of alumina ceramics and production method, which is applied in the field of production of high wear-resistant special alumina ceramic balls, can solve the problems of reducing the performance of ceramics, and achieve the effects of low raw material cost, easy promotion and industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

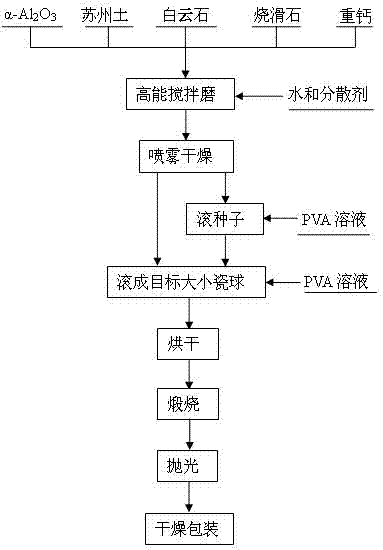

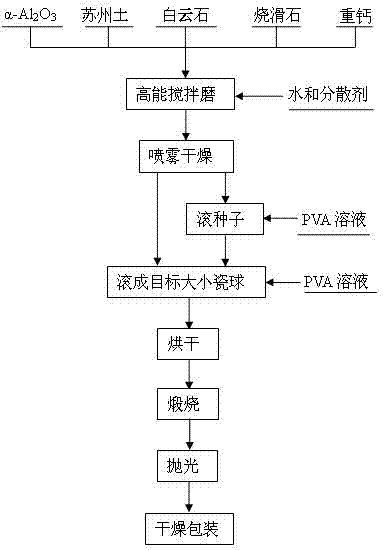

Method used

Image

Examples

Embodiment example 1

[0023] According to the ratio of 94.5wt% α-Al 2 o 3 , 3wt% Suzhou soil, 1.5wt% dolomite, 0.5wt% calcined talc, 0.5wt% heavy calcium Weigh 1000 kg of ceramic powder and place it in a high-energy stirring mill, add water and 0.1% polyacrylamine to make a solid content It is 60% slurry, milled for 120min, and spray-dried. After drying, the moisture content of the powder is 1%. Put the dried powder in a rolling ball machine, and spray the powder with a concentration of 0.2 while rolling the powder. wt% PVA solution, until the alumina ceramic ball seeds with a diameter of about 3mm are made; the prepared seeds are added to the ball rolling machine, and the powder and concentration of 0.5wt% PVA solution are continued until rolled into diameters After the ceramic ball green body is about 12mm, spray a small amount of water and let the green body roll for another 30 minutes; dry the ceramic ball green body to a moisture content of 2%; place the dried ceramic ball green body in a hig...

Embodiment example 2

[0025] According to the ratio of 89.5wt% α-Al 2 o 3 , 6wt% Suzhou soil, 2.0wt% dolomite, 1.5wt% calcined talc, 1.0wt% heavy calcium weigh 1000 kg and place it in a high-energy stirring mill, add water and 0.5% polyacrylic acid amine to make a solid content of 60% The slurry was ground for 150 minutes and spray-dried. After drying, the moisture content of the powder was 0.5%; the dried powder was slowly added to the rolling ball machine, and while the powder was rolling, it was sprayed with a concentration of 0.3wt% by spraying. PVA solution, until the aluminum oxide ceramic ball seeds with a diameter of about 4mm are made; the prepared seeds are placed in a ball rolling machine, and powder and concentration are continued to be added to a PVA solution with a concentration of 0.8wt%, until they are rolled into a diameter of about After the 12mm ceramic ball green body, spray a small amount of water, and let the green body roll for another 40 minutes; dry the ceramic ball green ...

Embodiment example 3

[0027] According to the ratio of 92.0wt% α-Al 2 o 3 , 4.5wt% Suzhou soil, 1.8wt% dolomite, 1.0wt% calcined talc, 0.7wt% heavy calcium weigh 1000 kilograms and place it in a high-energy stirring mill, add water and 1% polyacrylic acid amine to make a solid content of 60 % of the slurry, ball milled for 180min, spray-dried, the moisture content of the dried powder was 1.5%; the dried powder was slowly added to the rolling ball machine, while rolling the powder, spraying the concentration of 0.4wt in the form of spray % PVA solution, until making alumina ceramic ball seeds with a diameter of about 6mm; the prepared seeds are placed in a ball rolling machine, and continue to add powder and 1.0wt% PVA solution until rolling into a diameter of about 12mm After the ceramic ball green body, no longer spray PVA solution, and let the green body roll for another 30 minutes; dry the ceramic ball green body to a moisture content of 6%; put the dried ceramic ball green body in a high-tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com