Solar selective absorbing coating and preparation method thereof

An absorbing coating and selective technology, applied in the field of solar thermal utilization and thermal power generation, can solve the problems of easy oxidation, diffusion, failure and optical performance degradation of refractory metal particle clusters, and achieve good high temperature thermal stability, The effect of high absorption rate and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

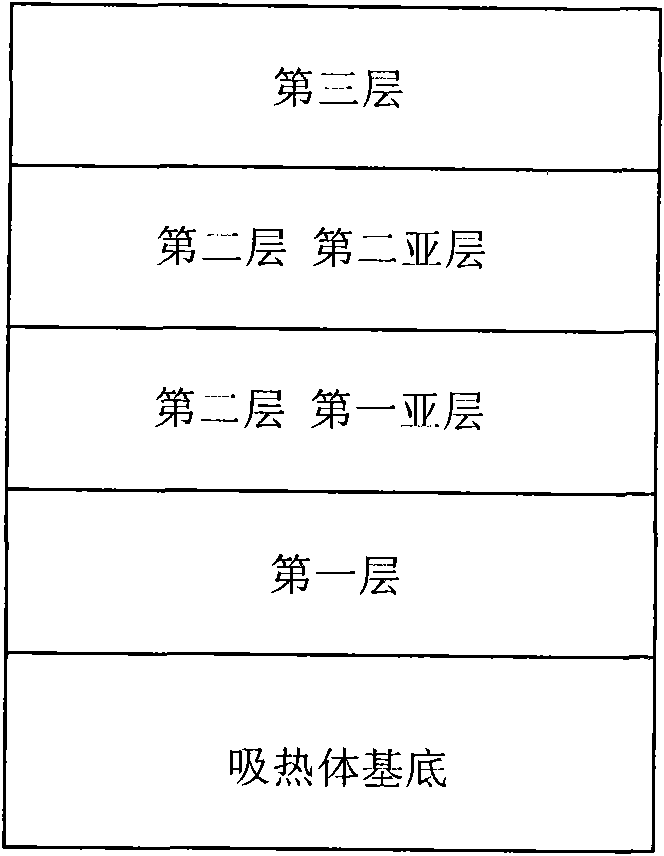

[0018] Embodiment 1: The present invention provides a solar selective absorption coating, which includes three layers: a first infrared reflection layer, a second absorption layer and a third anti-reflection layer.

[0019] The first layer is an infrared reflection layer, which is composed of a Mo metal film with a thickness of 200nm, and is prepared by direct current sputtering of a metal Mo target with Ar gas as a sputtering gas.

[0020] The second layer is the absorption layer, the composition of which is dispersed in the insulating medium Al by AlNi alloy clusters 2 o 3 The cermet layer in the structure is composed of two sublayers with different thickness and AlNi volume percentage, the thickness of the first sublayer is 50nm, the volume percentage of AlNi is 50%, and the thickness of the second sublayer is 30nm , AlNi volume percentage content is 30%. These two sub-layers have intrinsic absorption for the solar spectrum, and at the same time form an interference absor...

Embodiment 2

[0027] Embodiment two: prepare a kind of solar energy selective absorbing coating, comprise three layers: the first layer infrared reflection layer (this example adopts the copper substrate after polishing, because copper has good infrared reflection characteristic, so can adopt this substrate directly as Infrared reflective layer), the second layer of absorbing layer and the third layer of anti-reflection layer. The preparation steps are as follows:

[0028] Step 1: preparing the first infrared reflection layer. In this experiment, the polished copper sheet was selected as the substrate, because the infrared reflectivity of the copper sheet is already very high. In order to simplify the preparation process, the substrate was directly used as the infrared reflective layer. All the other preparation steps are the same as in Example 1.

[0029] The performance of the solar selective absorbing coating prepared in this embodiment is as follows: under the condition of air quality...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com