Method for improving calcium carbonate retention rate through adding calcium carbonate before pulp beating

A technology of calcium carbonate and retention rate, applied in the field of adding calcium carbonate to improve the retention rate of calcium carbonate, and can solve the problems of low retention rate of calcium carbonate and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

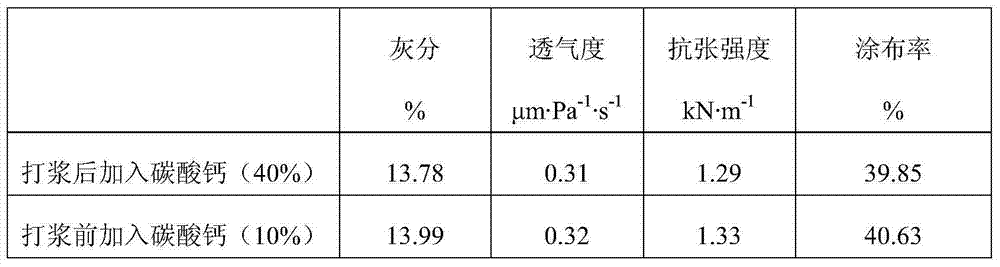

Embodiment 1

[0022] The preparation method for adding calcium carbonate before beating to improve the retention rate of calcium carbonate comprises the following steps:

[0023] 1) Soak the tobacco powder, tobacco stems, and shredded tobacco pieces in water to obtain a mixed pulp, and then extract and separate the mixed pulp to obtain soluble tobacco fibers and insoluble tobacco fibers;

[0024] 2) Mix and beat the insoluble tobacco fiber and calcium carbonate in step 1) to obtain a mixed pulp of stem end with a beating degree of 30±2°SR, wherein the amount of calcium carbonate is the above-mentioned tobacco powder, tobacco stem, and shredded tobacco flakes 10% of the dry weight of the mixed pulp;

[0025] 3) Add the outer fiber and chitosan with a beating degree of 44±2°SR to the slurry obtained in step 2), and after mixing evenly, obtain the pre-sheet slurry, and make the pre-sheet slurry into a substrate, wherein , the amount of outer fiber is 12.5% of the dry weight of the mixed pul...

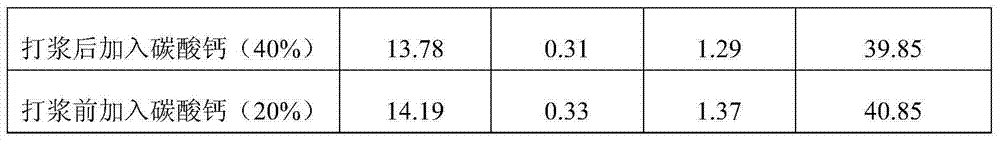

Embodiment 2

[0033] A preparation method for adding calcium carbonate before beating to improve the retention rate of calcium carbonate, comprising the following steps:

[0034] 1) Soak the tobacco powder, tobacco stems, and shredded tobacco pieces in water to obtain a mixed pulp, and then extract and separate the mixed pulp to obtain soluble tobacco fibers and insoluble tobacco fibers;

[0035] 2) Mix and beat the insoluble tobacco fiber and calcium carbonate in step 1) to obtain a mixed pulp of stem end with a beating degree of 30±2°SR, wherein the amount of calcium carbonate is the above-mentioned tobacco powder, tobacco stem, and shredded tobacco flakes 20% of the dry weight of the mixed pulp;

[0036] 3) Add the outer fiber and chitosan with a beating degree of 44±2°SR to the slurry obtained in step 2), and after mixing evenly, obtain the pre-sheet slurry, and make the pre-sheet slurry into a substrate, wherein , the amount of outer fiber is 10% of the dry weight of the mixed pulp in...

Embodiment 3

[0045] The preparation method for adding calcium carbonate before beating to improve the retention rate of calcium carbonate comprises the following steps:

[0046] 1) Soak the tobacco powder, tobacco stems, and shredded tobacco pieces in water to obtain a mixed pulp, and then extract and separate the mixed pulp to obtain soluble tobacco fibers and insoluble tobacco fibers;

[0047] 2) Mix and beat the insoluble tobacco fiber and calcium carbonate in step 1) to obtain a slurry with a beating degree of 30±2°SR, wherein the amount of calcium carbonate is the mixed slurry of the above-mentioned tobacco powder, tobacco stems, and shredded tobacco flakes 30% of dry weight;

[0048] 3) Add the outer fiber and chitosan with a beating degree of 44±2°SR to the slurry obtained in step 2), and after mixing evenly, obtain the pre-sheet slurry, and make the pre-sheet slurry into a substrate, wherein , the amount of outer fiber is 15% of the dry weight of the mixed pulp in step 2); the amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com