Method for preparing photocuring-formed high-density ceramic

A light-curing molding and ceramic technology, which is applied in the field of ceramic preparation, can solve the problems of long production cycle, complex and precise ceramic body shape, and high production cost, so as to reduce the production cycle, solve the deformation of the green body, and uniform shrinkage in all directions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

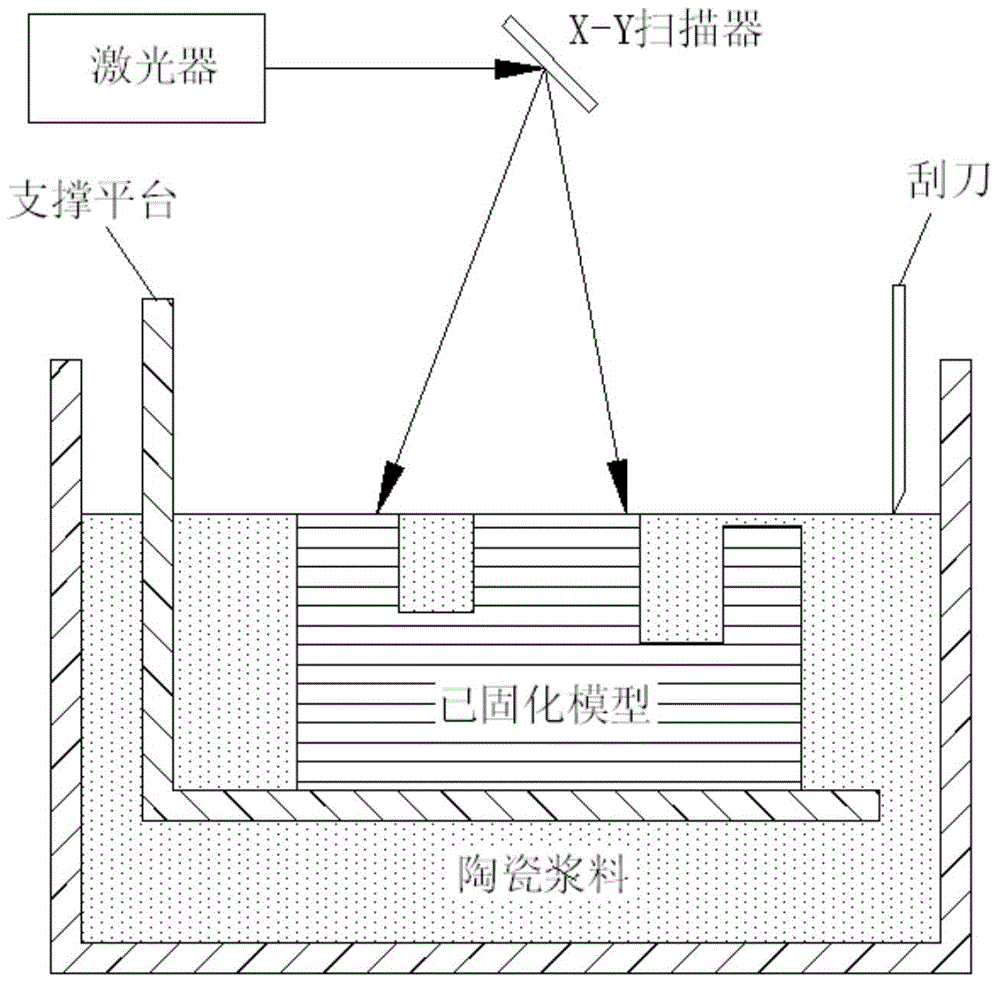

Method used

Image

Examples

Embodiment 1

[0035] This embodiment provides a method for preparing a light-cured high-density ceramic, and the specific steps are as follows:

[0036] (1) Preparation of slurry

[0037] Preparation of premix: take 665g deionized water and 160g glycerin as solvent (accounting for 75% of the mass of premix) respectively; 25% of the mass of the premix). Mix the organic solute and the solvent evenly to dissolve all the organic solute to obtain 1100 g of a slightly yellowish transparent premixed solution.

[0038] Slurry preparation: take the above-mentioned premix solution (38.85%), and weigh 30g polyvinylpyrrolidone (dispersant, 1.06%), 1700g α-alumina (ceramic powder, 60%; particle diameter≤0.2μm, Purity 99.99%), 1.5 g 2-hydroxy-2-methyl-1-phenyl-1-propanone (photoinitiator 1173, 0.05%). Add dispersant to the premixed liquid and mix evenly, then add ceramic powder to the premixed liquid and ball mill for 8 hours to obtain the initial slurry; place the initial slurry in a negative pressur...

Embodiment 2

[0050] This embodiment provides a method for preparing a light-cured high-density ceramic, and the specific steps are as follows:

[0051] (1) Preparation of slurry

[0052] Preparation of premix: take 930g deionized water and 60g glycerin as solvent (accounting for 90% of the mass of premix) respectively; 10% of the mass of the premix). Mix the organic solute and the solvent evenly to dissolve all the organic solute to obtain 1100 g of a slightly yellowish transparent premixed solution.

[0053] Slurry preparation: take the above premix (23.26%), and weigh 100g ammonium citrate (dispersant, 2.1%), 3500g α-alumina (ceramic powder, 74%; particle diameter≤0.5μm, purity is 99.99 %), 30 g of 2-hydroxy-2-methyl-1-phenyl-1-propanone (photoinitiator 1173, 0.63%). Add dispersant to the premixed liquid and mix evenly, then add ceramic powder to the premixed liquid and ball mill for 48 hours to obtain the initial slurry; place the initial slurry in a negative pressure environment and...

Embodiment 3

[0065] This embodiment provides a method for preparing a light-cured high-density ceramic, and the specific steps are as follows:

[0066] (1) Preparation of slurry

[0067] Preparation of premix: take by weighing 440g deionized water and 220g glycerin as solvent (accounting for 60% of the mass of premix) respectively; 40% of the mass of the premix). Mix the organic solute and the solvent evenly to dissolve all the organic solute to obtain 1100 g of a slightly yellowish transparent premixed solution.

[0068] Slurry: Take the above premix (59.46%), and weigh 1g of ammonium citrate (dispersant, 0.05%) and 734g of α-alumina (ceramic powder, 39.68%; particle diameter≤0.1μm, purity 99.99%) %), 15 g of 2-hydroxy-2-methyl-1-phenyl-1-propanone (photoinitiator 1173, 0.81%). Add dispersant to the premixed liquid and mix evenly, then add ceramic powder to the premixed liquid and ball mill for 3 hours to obtain the initial slurry; place the initial slurry in a negative pressure enviro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com