Phase-transition composite material, preparation method and application thereof

A phase-change composite material and phase-change material technology, applied in the field of external wall insulation or temperature adjustment, and the preparation of phase-change composite materials, can solve problems such as insufficient phase-change energy storage capacity, poor flame-retardant performance, and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] Paraffin wax with a melting point of 44° C., ethylene-vinyl acetate copolymer particles with a vinyl acetate monomer unit content of 14% by weight and a melting point of 90° C. as an inorganic filler have a bulk density of 45 kg / m 3 Expanded perlite with a honeycomb structure inside with an average particle size of 3.0mm, graphite as a thermal conductivity enhancer, and a composite flame retardant of magnesium hydroxide and aluminum hydroxide with an average particle size of 200nm (wherein magnesium hydroxide and hydrogen Aluminum oxide accounts for 45% by weight and 55% by weight respectively) and is weighed according to the ratio of 50%, 32%, 10%, 5% and 3%. Adjust the temperature of the temperature-controllable heating furnace at 48±1°C, add paraffin to it to melt into a liquid, remove the paraffin to a mixer, immediately add EVA particles at room temperature to the paraffin, and use a stirrer at 100 rpm Stir at a constant stirring rate for 1-2min, cool to room tempe...

Embodiment 2

[0083] Repeat Example 1, the difference is: EVA is replaced by high density polyethylene, the density of this polymer is 0.956g / cm 3 , the melting point was 130°C, and the melt-blending temperature in the twin-screw extruder was changed to 140°C.

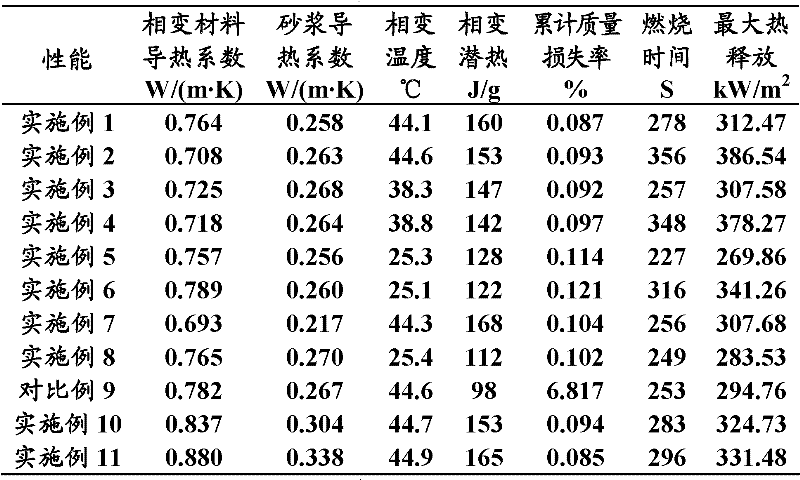

[0084] The test results are shown in Table 1.

Embodiment 3

[0086] Repeat Example 1, except that the paraffin wax is replaced by paraffin wax with a melting point of 38° C., and the temperature of the temperature-controllable heating furnace is adjusted at 42±1° C. accordingly.

[0087] The test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition enthalpy | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com