System, method and computer program product for forming a reconfigurable cavity and an expandable shoe last and for constructing a shoe

a technology of reconfigurable cavity and expandable shoe body, applied in the field of apparatus, systems and methods for producing shoe body, can solve the problems of high labor intensity, disadvantageous use of mechanical machinery for lasting operation, frequent complicated maintenance,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0091] A preferred embodiment of the invention is discussed in detail below. While specific exemplary implementation embodiments are discussed, it should be understood that this is done for illustration purposes only. A person skilled in the relevant art / profession recognizes that other components and configurations may be used without parting from the spirit and scope of the invention.

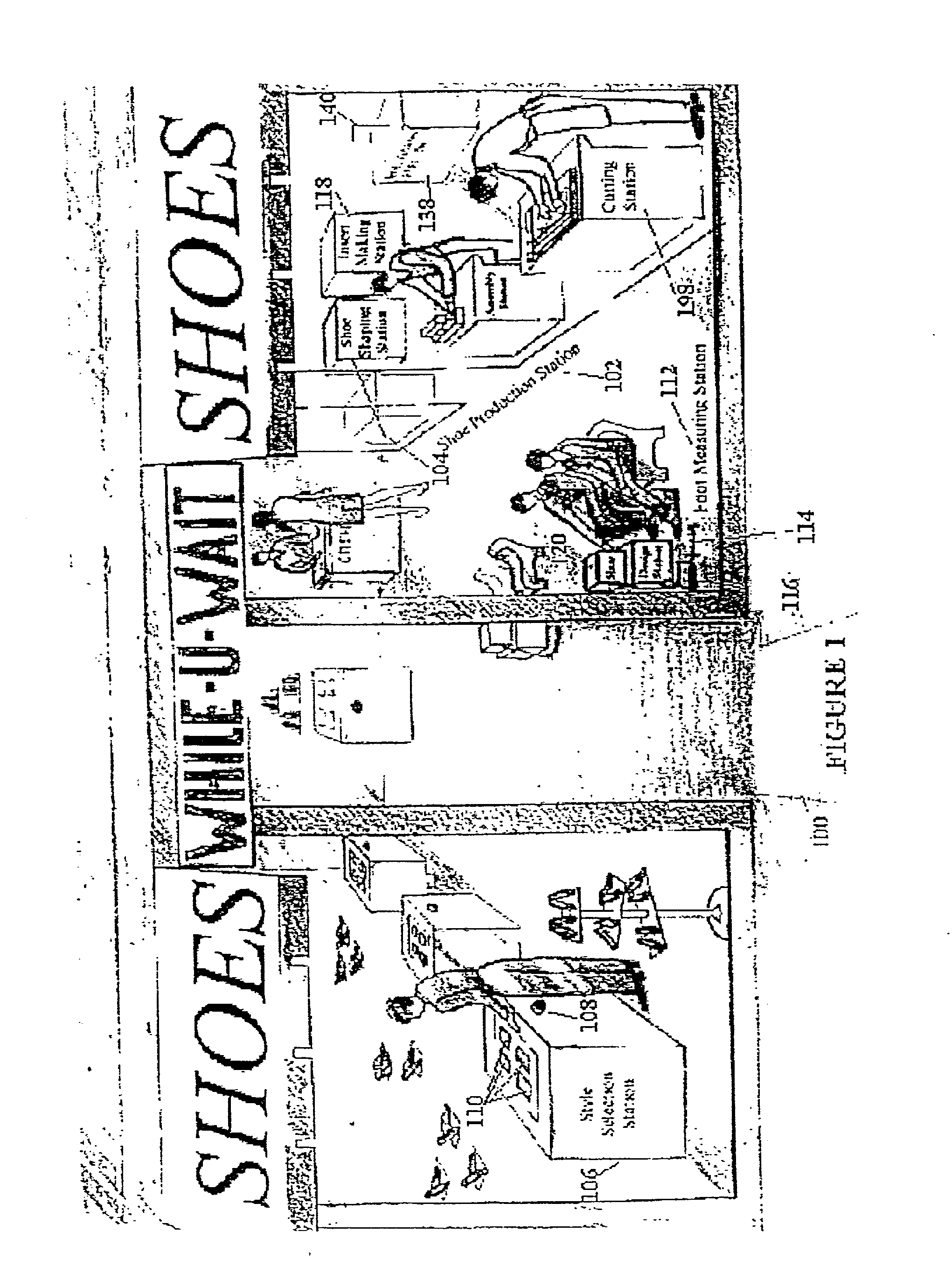

[0092] An example embodiment of a blow molding apparatus 104 as an element of a custom-made shoe making system 102 in accordance with the present invention is illustrated in an exemplary shoe store layout 100 of FIG. 1. The store layout 100 can include a style selection area 106, which can allow a customer to choose a desired shoe style from a shoe catalog. To help the customer to choose a virtual pair of shoes, a camera 108 can capture lower body image (waist down) from different directions and can display each image on a separate display screen 110. After choosing the most suitable shoe style, the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com