Polypropylene with high melt strength and product thereof

A high melt strength, propylene technology, used in the fields of thermoforming products, blown films and blow molded products, preparation of foamed products, and biaxially oriented films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

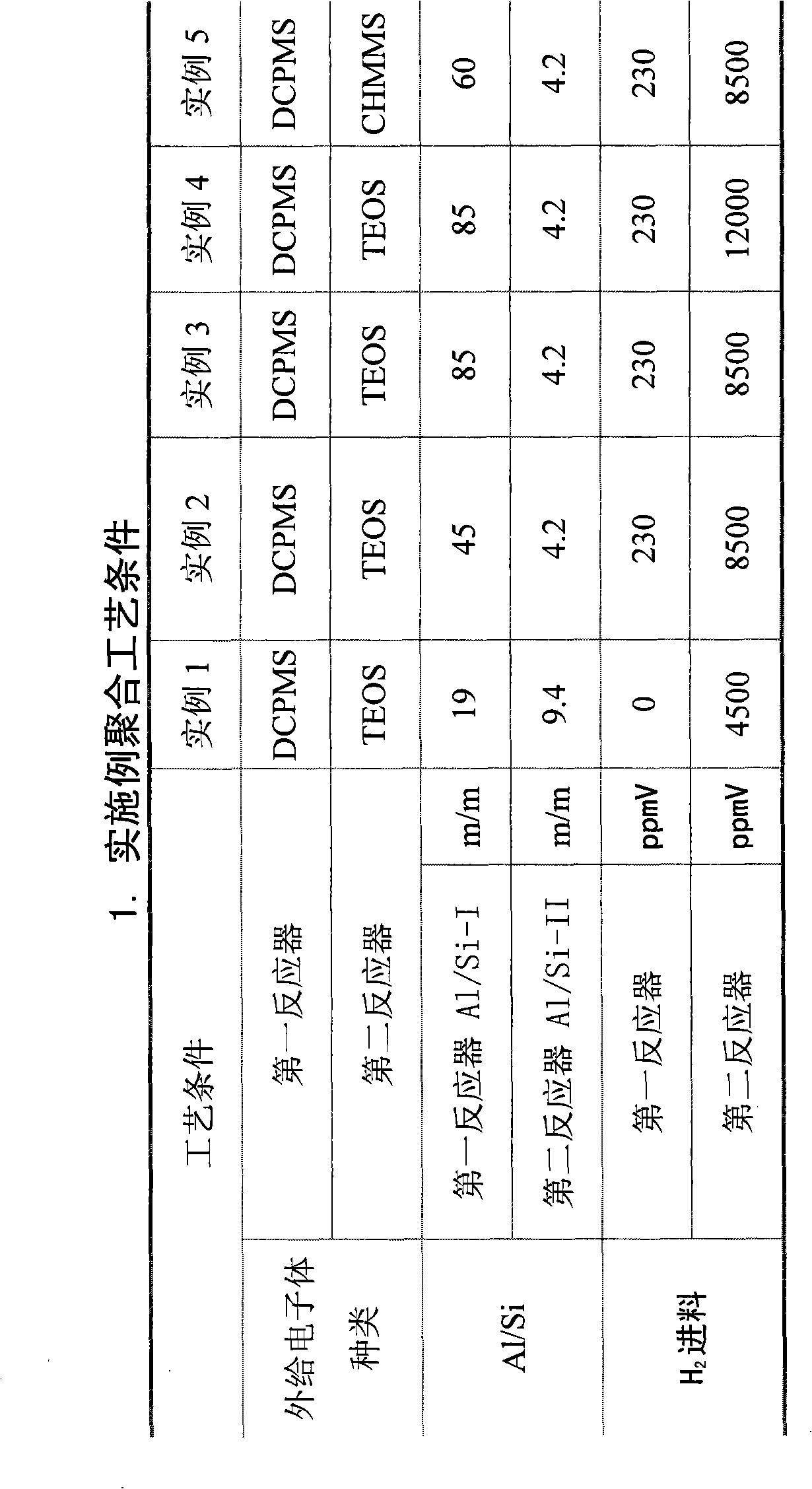

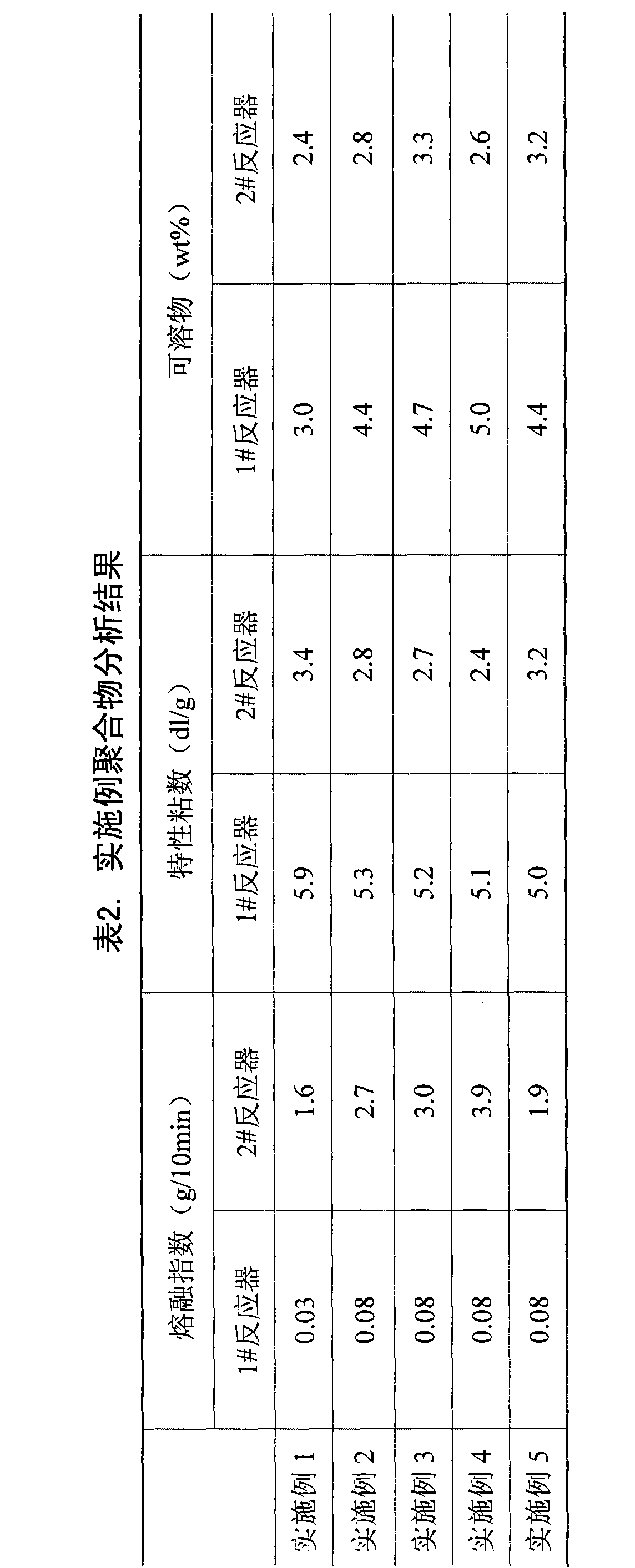

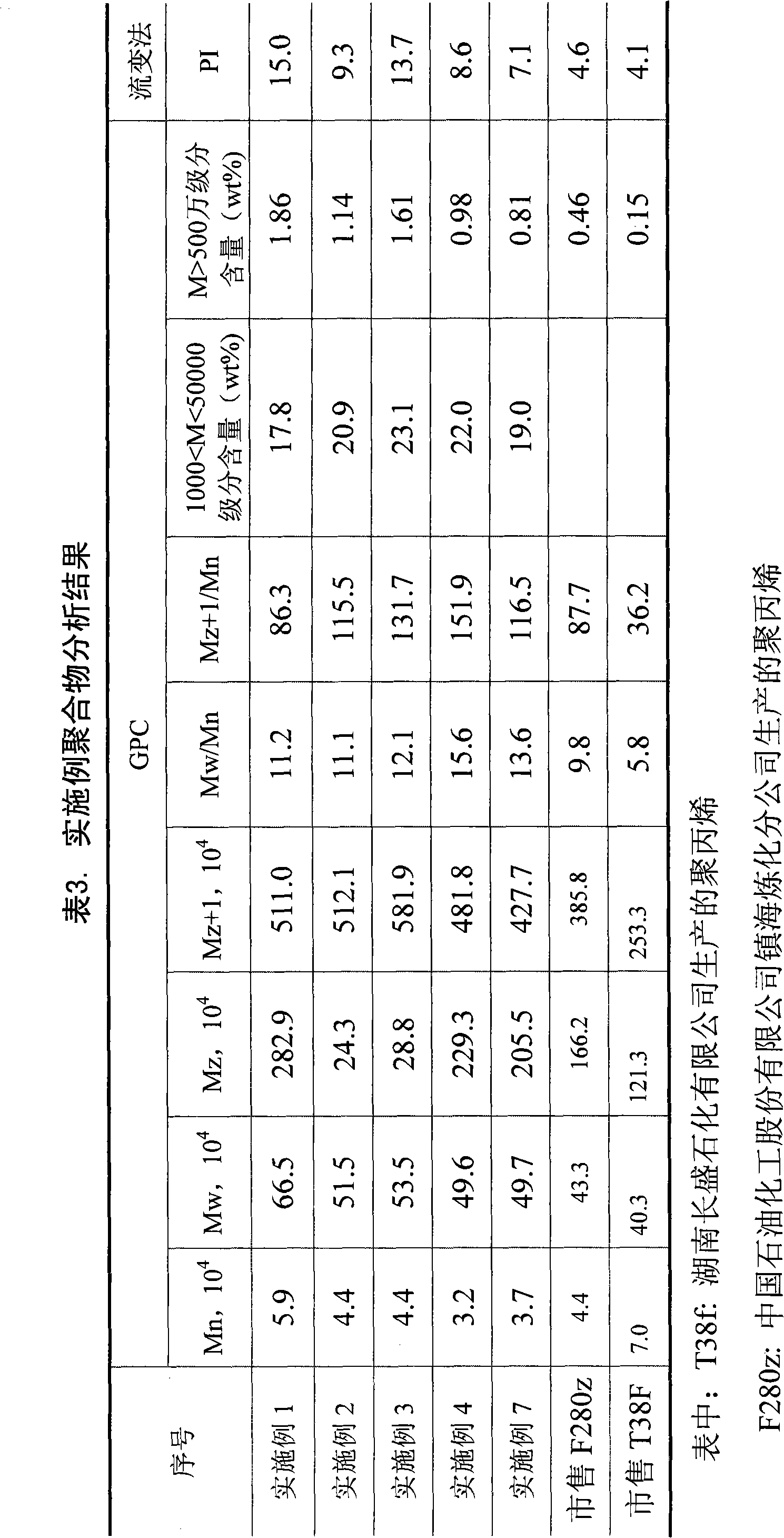

[0057] The polymerization reaction was carried out on a polypropylene pilot plant. Its main equipment includes prepolymerization reactor, first loop reactor and second loop reactor. Polymerization method and steps are as follows:

[0058] (1) Prepolymerization reaction:

[0059] The main catalyst (titanium-containing solid catalyst active component) is obtained by the method described in Example 1 of Chinese Patent CN93102795, its Ti content: 2.4wt%, Mg content 18.0wt%, di-n-butyl phthalate content: 13wt %.

[0060] The main catalyst, co-catalyst (triethylaluminum), and the first external electron donor (dicyclopentyldimethoxysilane, DCPMS) were pre-contacted at 10°C for 20 minutes, and then continuously added to the pre-polymerization reactor for pre-polymerization. In the polymerization reactor, the pre-polymerization is carried out in the environment of the propylene liquid phase body, the temperature is 15°C, and the residence time is about 4 minutes. Under this conditi...

Embodiment 2

[0069] Same as Example 1, except that a small amount of hydrogen is added to the make-up propylene feed of the first loop reactor, and the hydrogen concentration detected by online chromatography is 230 ppmV. The hydrogen feed amount in the make-up propylene feed to the second loop reactor was adjusted to 8500 ppmV. By adjusting the feed amount of the external electron donor, the Al / Si-I was adjusted to 45 (weight ratio), and the Al / Si-II was adjusted to 4.2 (weight ratio). The addition amount of cocatalyst triethylaluminum is unchanged.

Embodiment 3

[0071] Same as Example 2, except that the Al / Si-I is adjusted to 85 (weight ratio) by adjusting the feed amount of the external electron donor. The addition amount of cocatalyst triethylaluminum is unchanged. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com