Epoxy resin composition, glue film made of same and preparation method

A technology of epoxy resin and production method, which is applied in the field of epoxy resin composition, can solve the problem of poor thermal conductivity, moisture absorption resistance, punching resistance, low thermal resistance stability of metal-based copper-clad laminates, and difficult Ensure the thickness of the thermally conductive adhesive layer, etc., to achieve the effect of smooth appearance, material saving and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

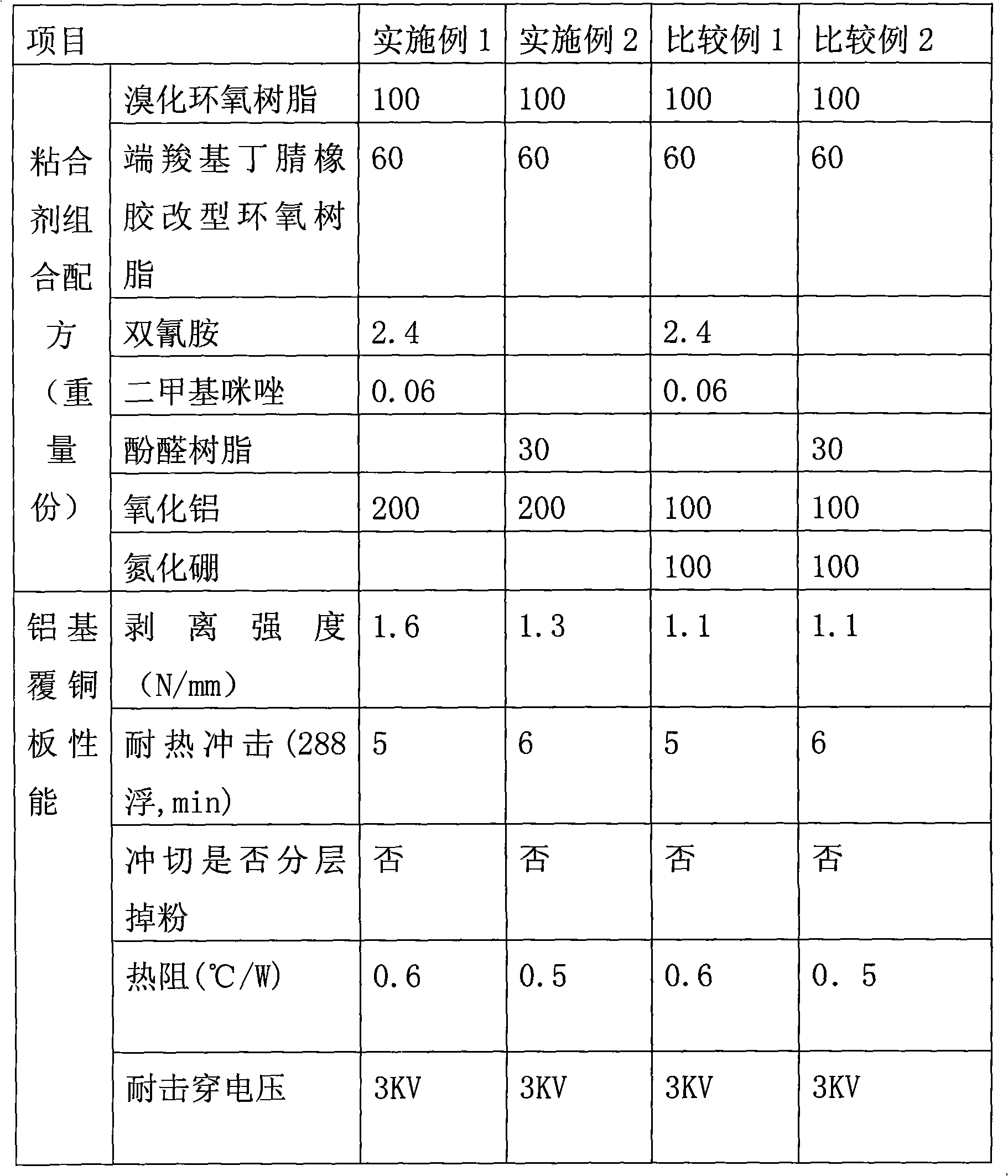

Embodiment 1

[0037] 100 parts by weight of brominated epoxy resin (450g / eq of epoxy equivalent, 20% of bromine content, 80% of solid content), 60 parts by weight of modified epoxy resin of carboxy-terminated nitrile rubber (product model RF928, produced by U.S. CVC Company) , dicyandiamide (2.4 parts by weight produced by Ningxia Darong Chemical Industry Co., Ltd., 0.06 parts by weight of dimethylimidazole (produced by Shikoku Chemical Industry in Japan), 200 parts by weight of aluminum oxide (produced by Wanjing, Hangzhou), with methyl ethyl ketone as the solvent regulation system solid content is 75%.

Embodiment 2

[0039] 100 parts by weight of brominated epoxy resin (450g / eq of epoxy equivalent, 20% of bromine content, 80% of solid content), 60 parts by weight of modified epoxy resin of carboxy-terminated nitrile rubber (product model RF928, produced by U.S. CVC Company) , 30 parts by weight of phenolic resin, 200 parts by weight of aluminum oxide (produced by Hangzhou Wanjing), and using butanone as a solvent to adjust the solid content of the system to be 75%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com