Protective knit gloves

a technology of knit gloves and knit yarn, applied in gloves, clothing, clothing, etc., can solve the problems of inability to fit fibers into the cross section of yarn, inconvenient use, and inability to protect the skin of the glove, and achieve the effect of exceptional physical/mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015]Unless otherwise defined, all technical and scientific terms used herein have the same meaning as commonly understood by one of ordinary skill in the art to which this invention belongs.

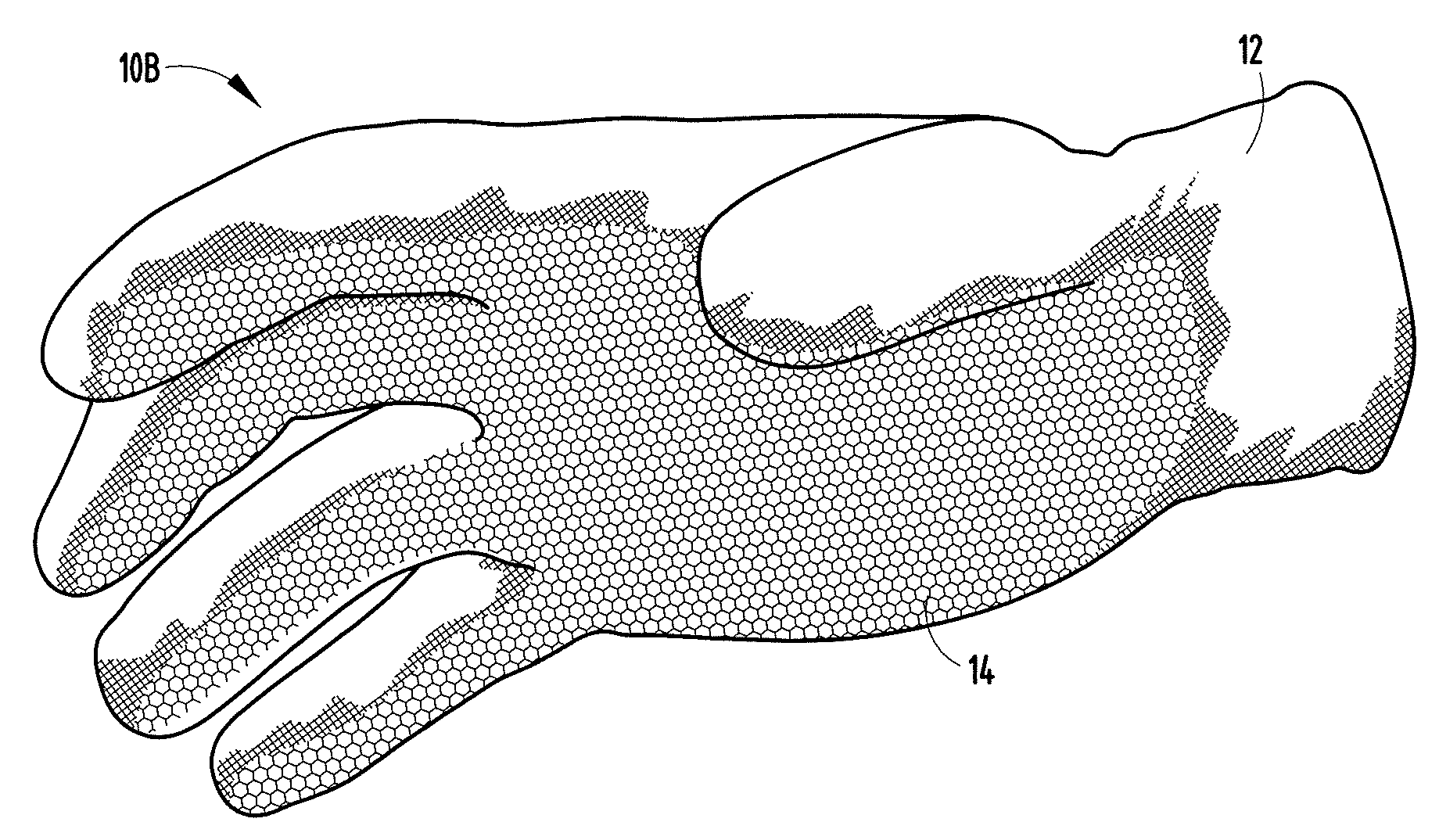

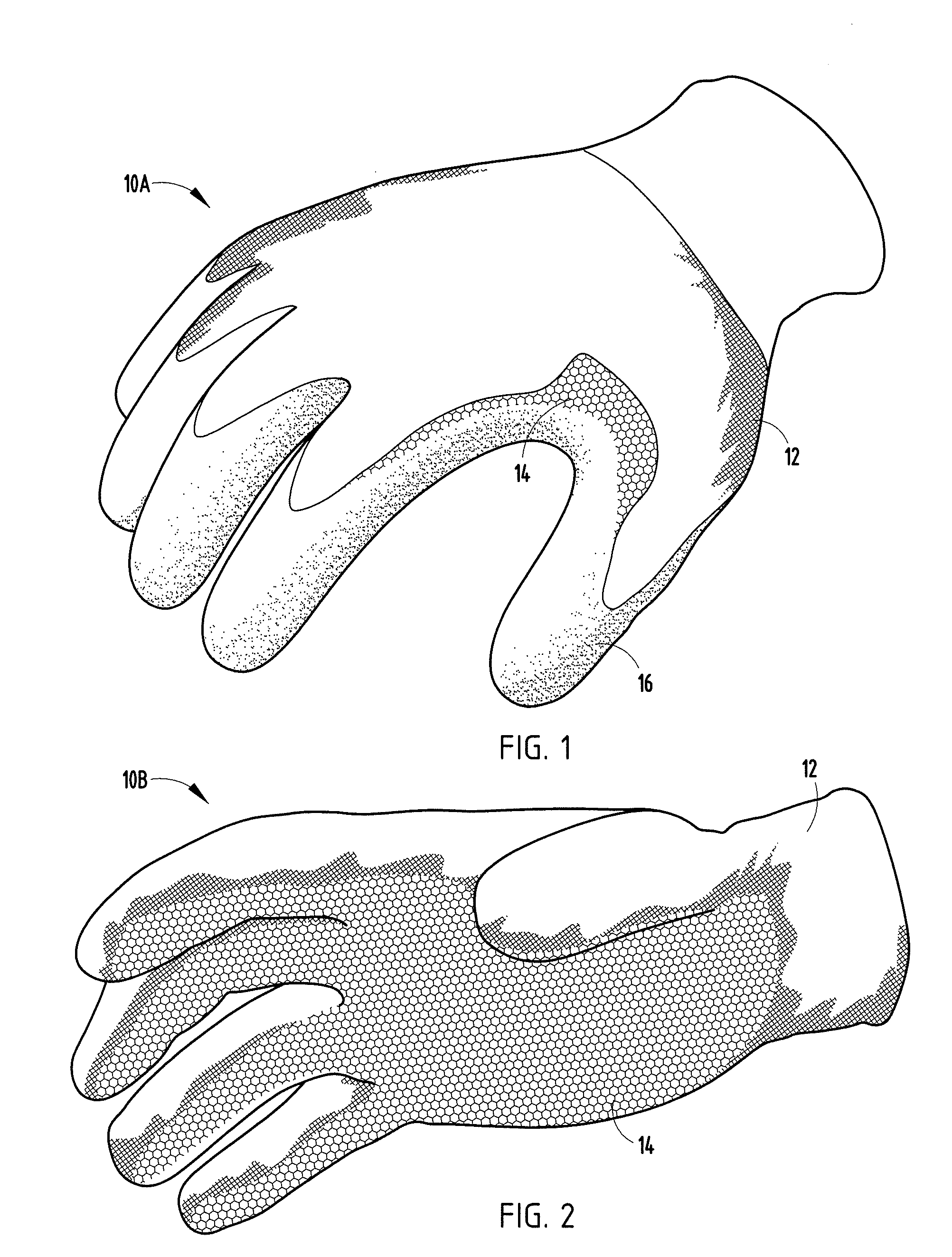

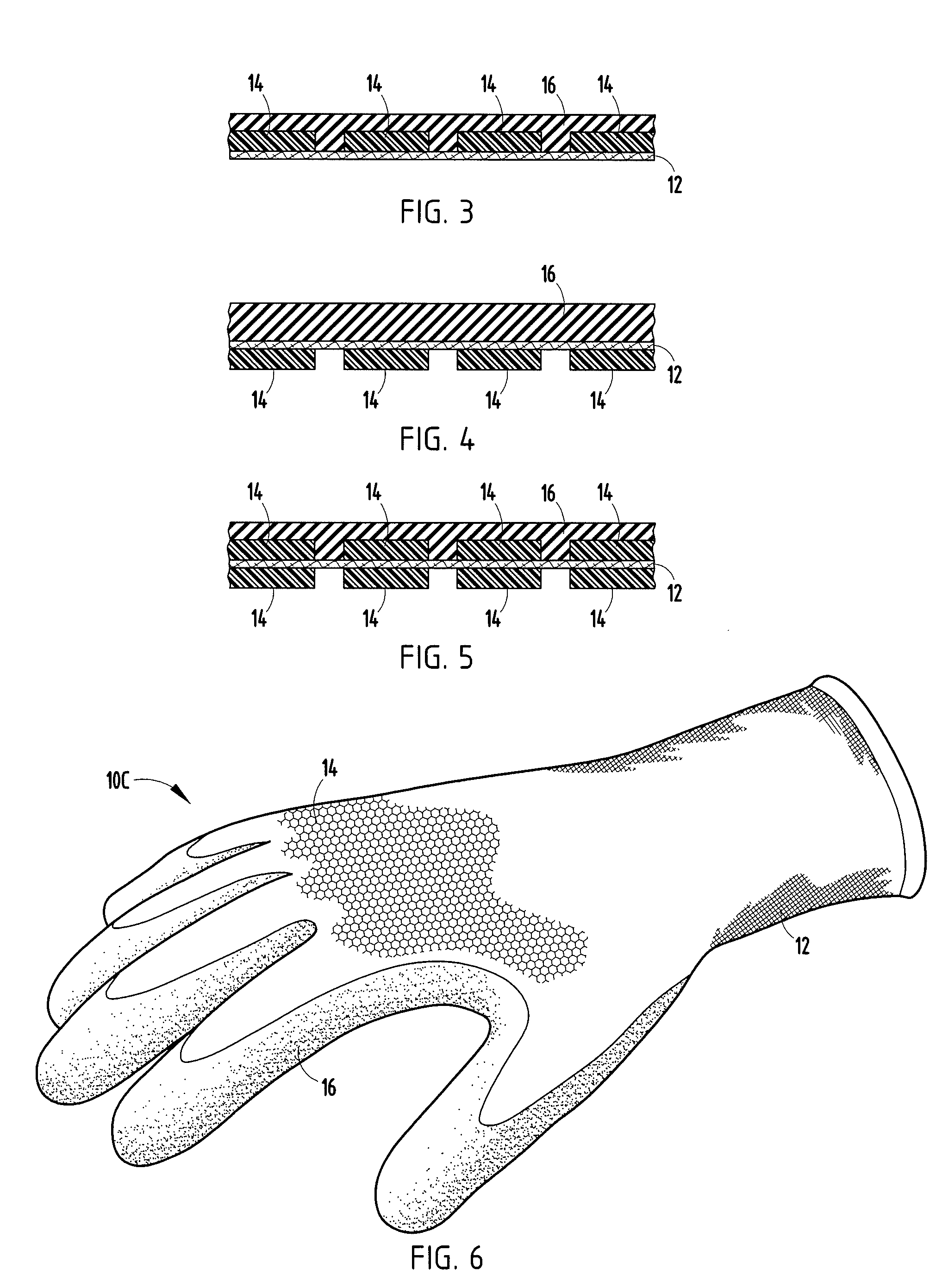

[0016]FIG. 1 illustrates a typical construction of the protective knit glove 10A with a plurality of spaced apart rigid plates 14 directly adhered to an area on the outside surface of a knit glove shell 12. The base of the construction is the knit glove shell 12, which can be made using an automated knitting machine. The yarns used to make the knit glove can be made with cotton, cotton / lycra, polyamide (Nylon), polyaramid (Kevlar®), Para-Aramid (Twaron), ultra-high molecular weight polyethylene (UHMWPE, Spectra®, Dyneema®), glass, or other high fibers. Optionally, combinations of these fibers and sometimes steel fibers can be used. In addition, the knit glove shells used may be homogenous, meaning comprised of a consistent set of yarns / fibers, or may use different types of fibers in different a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| gap size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com