Special material for automotive seal strip and preparation method thereof

A technology for strips and automobiles, which is applied in the field of special materials for automobile sealing strips and its preparation, can solve the problems of complex processing technology, high production cost, and high total cost, and achieve the effects of simple processing technology, easy recycling of materials, and reduction of raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

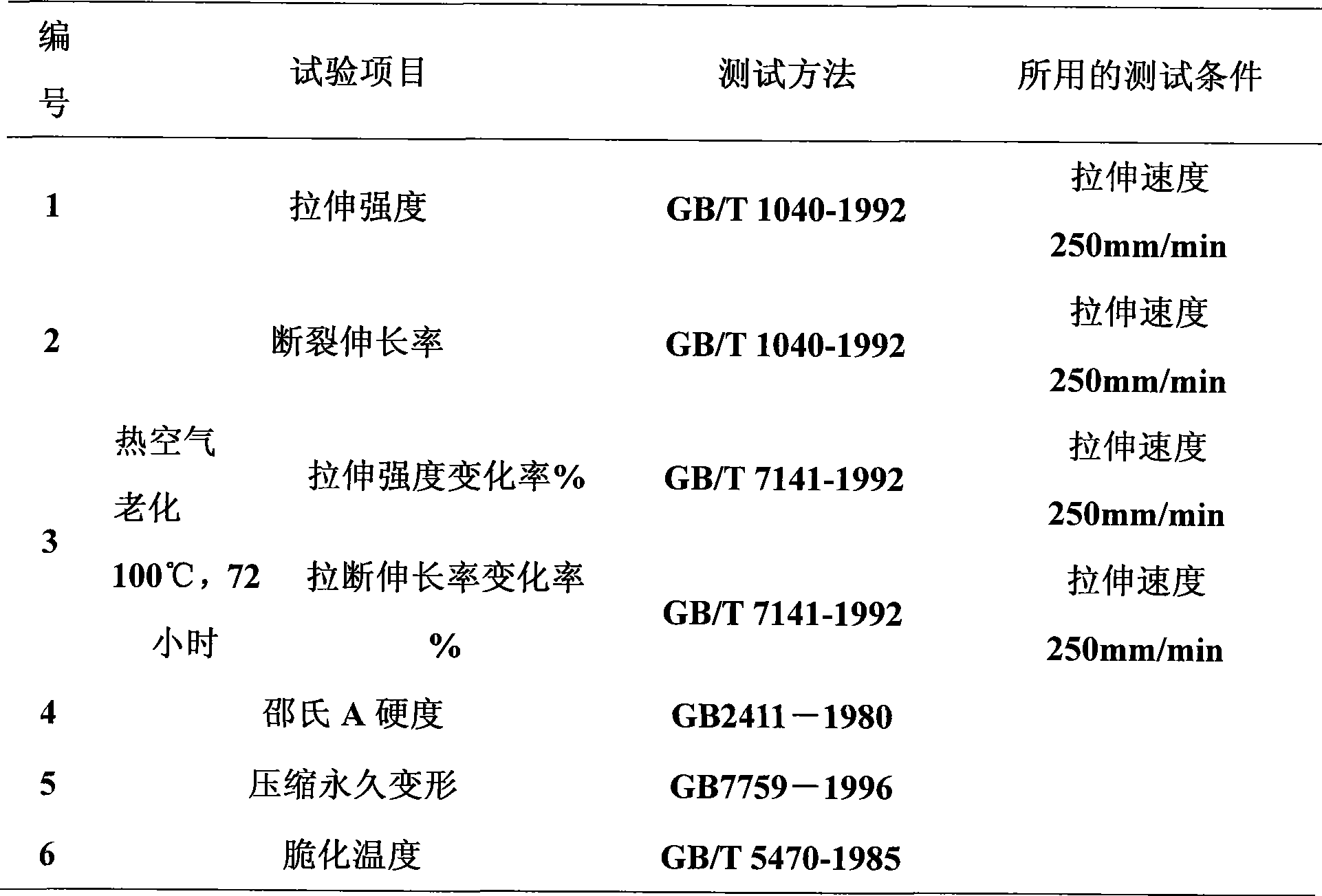

Image

Examples

Embodiment 1

[0044] The process formula is as follows:

[0045] PVC2500 (PVC with a degree of polymerization of 2500) 70

[0046] Component one: NBR (nitrile rubber) 30

[0047] Plasticizer 1: ATBC (trioctyl citrate) 70

[0048] Plasticizer 2: EVA 3

[0049] Stabilizer 1: Organotin 1.2

[0050] Stabilizer 2: Epoxidized soybean oil 2

[0051]Lubricant: HST (stearic acid) 0.2

[0052] Inorganic filler: calcium carbonate 10

[0053] Colorant: carbon black paste 50

[0054] Vulcanizing agent: DCP 0.1

[0055] Vulcanization aid: TAIC (triisocyanuric acid urate) 3

[0056] Put PVC2500, vulcanizing agent DCP, inorganic filler calcium carbonate, colorant carbon black pulp, lubricant stearic acid, heat stabilizer-organotin and heat stabilizer diepoxidized soybean oil into a high-speed mixer according to the ratio of raw materials mix. The stirring speed is 120-150 rpm. Add plasticizer 1 ATBC and plasticizer 2 EVA three times during the stirring process.

[0057] Add plasticizer 1 ATBC a...

Embodiment 2

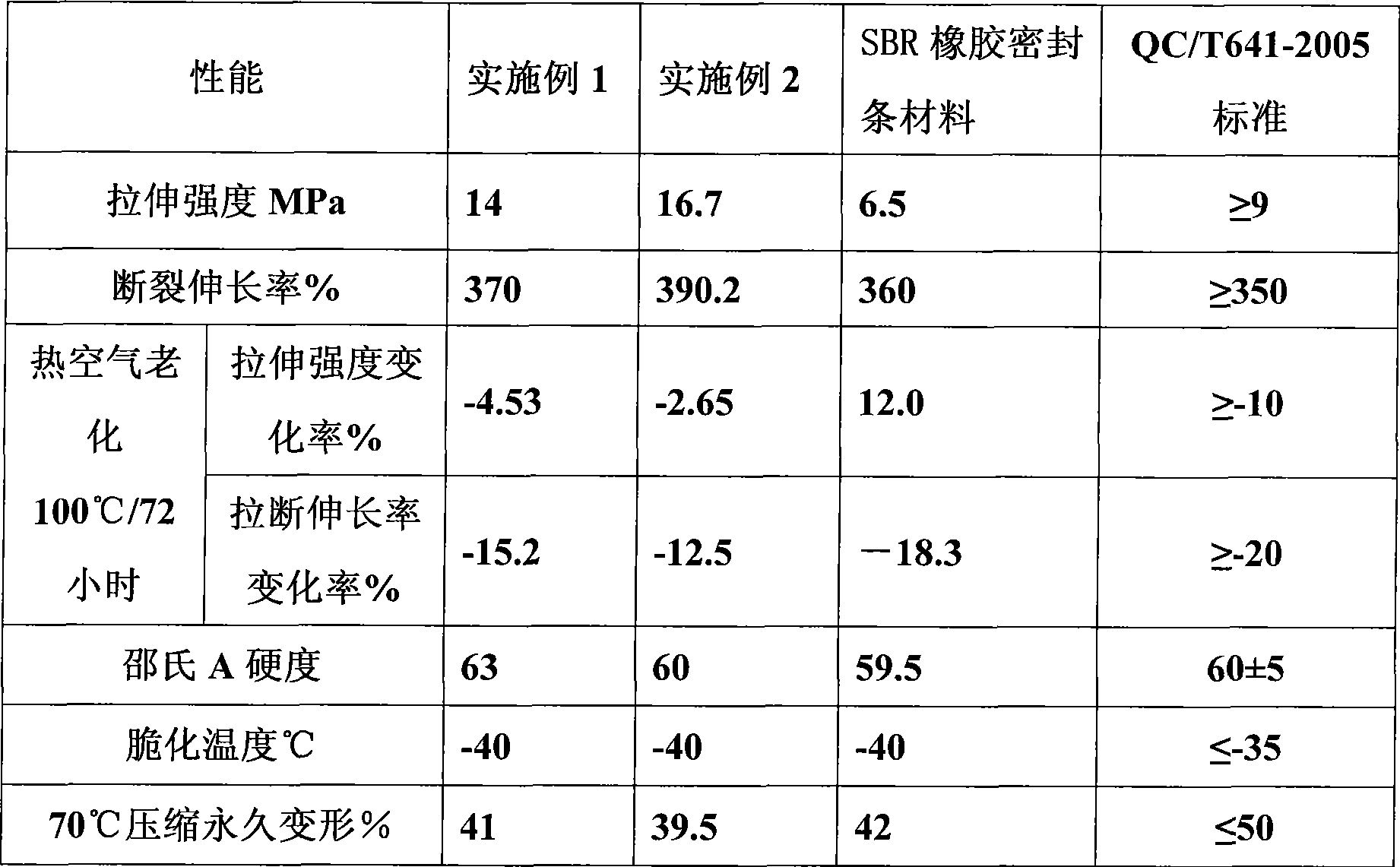

[0063] Same as Example 1, the difference is that the degree of polymerization of PVC is 3000, and the mechanical properties of the obtained material are shown in Table 2.

[0064] Compare the experimental results with the standard QC / T641-2005 for rubber sealing strips and automobile sealing strips, see Table 2.

[0065] Table 2 Properties of automotive weather strip materials

[0066]

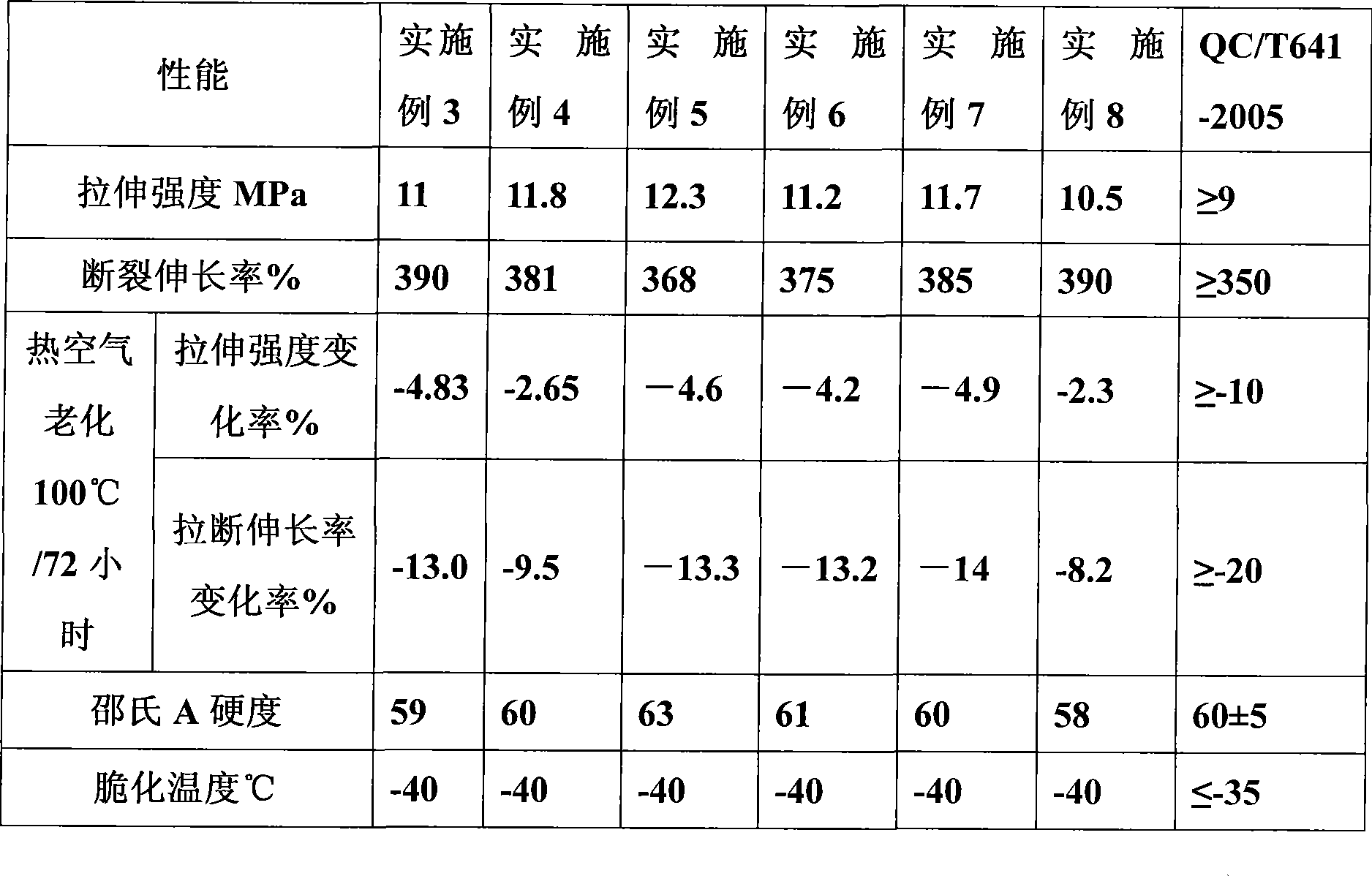

Embodiment 3

[0068] The process formula is as follows:

[0069] PVC1300 70

[0070] Component one NBR 30

[0071] Plasticizer-ATBC 70

[0072] Plasticizer II EVA 3

[0073] Stabilizer lead monocyanurate 1.2

[0074] Stabilizer Diepoxidized Soybean Oil 2

[0075] Lubricant HST 0.2

[0076] filler calcium carbonate 10

[0077] Colorant carbon black paste 50

[0078] Vulcanizing agent DCP 0.1

[0079] Vulcanization aid TAIC 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com