Polishing cerium oxide disk and its making method

A technology of polishing disc and cerium oxide, which is used in manufacturing tools, grinding/polishing equipment, optical surface grinders, etc., to achieve the effect of no grinding head falling off, firm chassis, and good grinding head firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

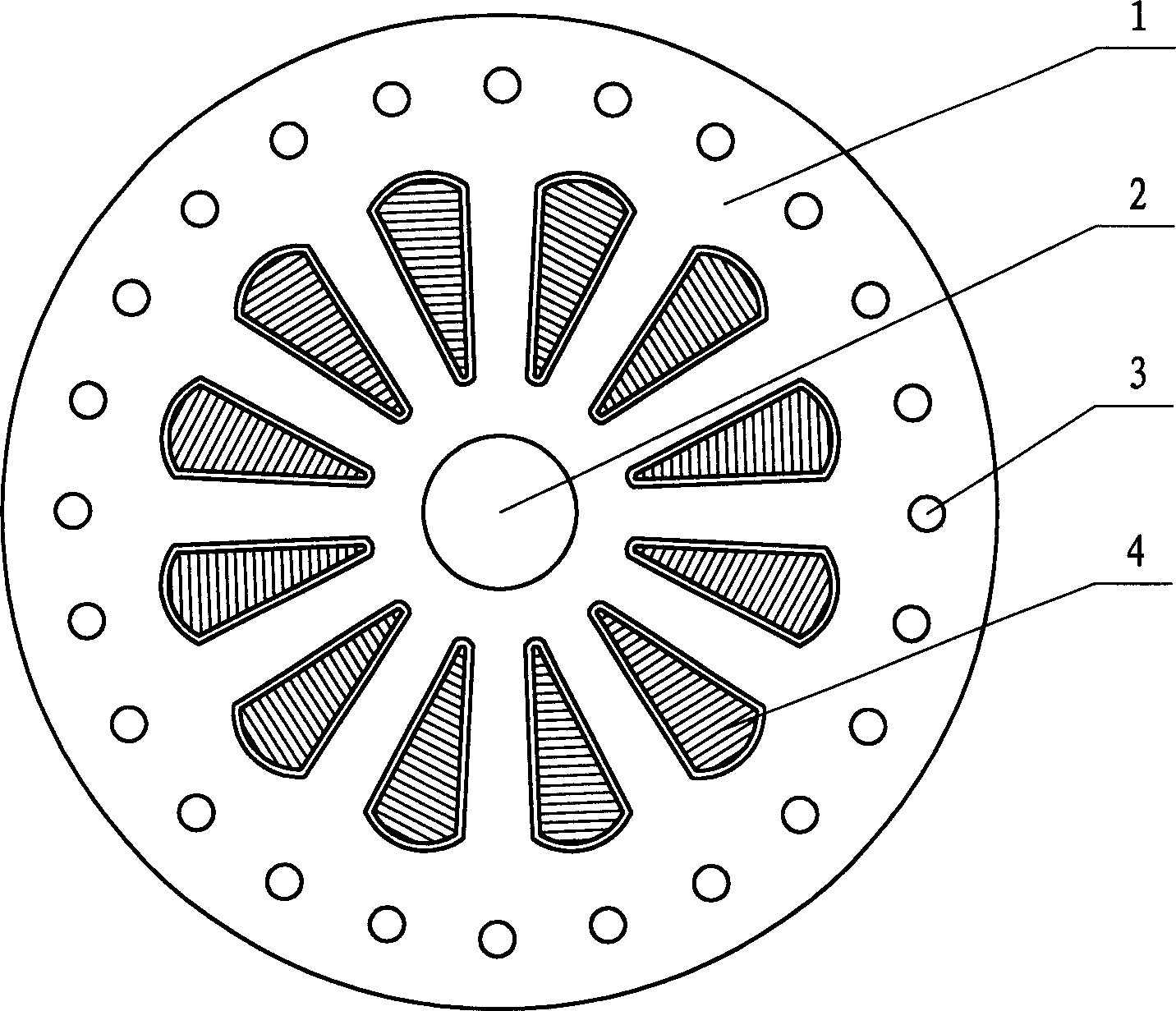

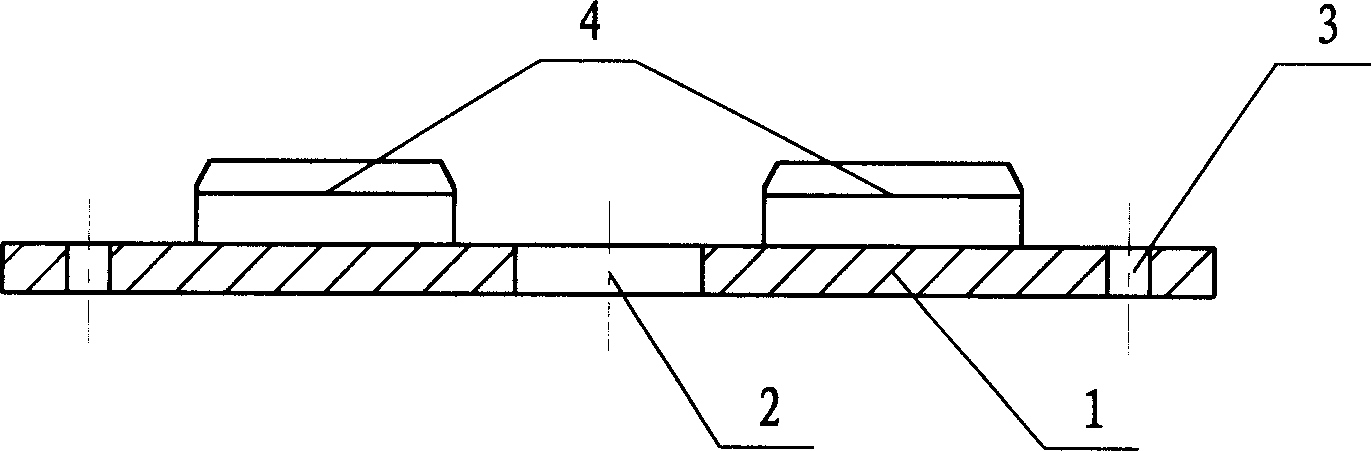

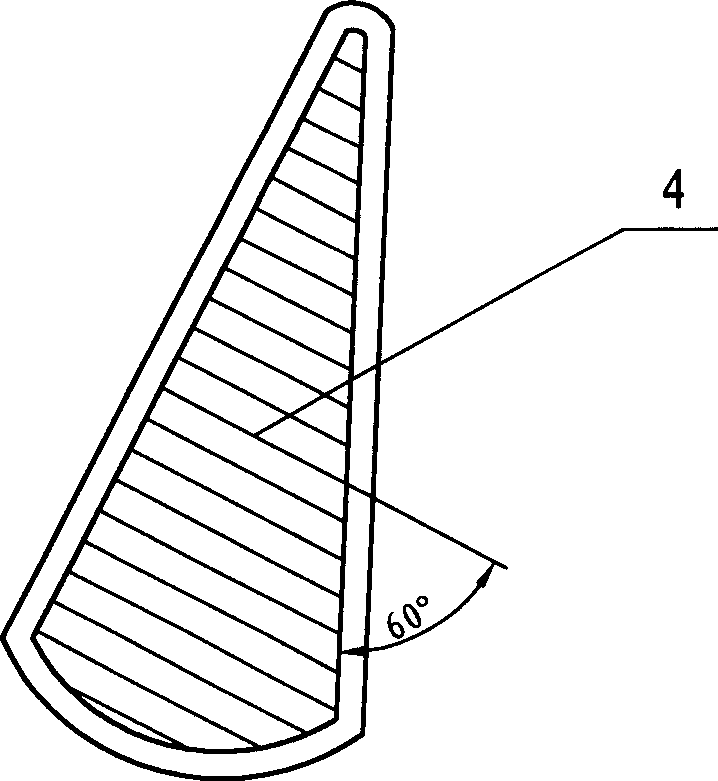

[0072] Such as Figure 1 ~ Figure 4 As shown, the cerium oxide polishing disc of the present embodiment is composed of a circular chassis 1, a central hole 2, a side hole 3 and a grinding head 4; the grinding head 4 is composed of an even number of identical fan-shaped blocks whose tops are arc-shaped; Chassis 1 is fixedly connected to the rotating disk of the polishing machine through central hole 2 and side hole 3; the bottom of grinding head 4 is bonded to chassis 1 with adhesive A, and the upper half of the edge is chamfered, and the angle of chamfering is at the same angle as the vertical direction. The angle of 30 degrees; the grinding head 4 is made by radially bonding 40 to 150 layers of grinding discs with adhesive B, and processed. The grinding discs are at right angles to one side of the sector and 60 degrees to the other side of the sector, wherei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com