Cold-resistant wear-resistant nitrile rubber sealing material and preparation method thereof

A technology of nitrile rubber and sealing material, which is applied in the field of nitrile rubber sealing material and its preparation, can solve the problems of poor compression permanent deformation performance, influence material processing stability, large compression permanent deformation, etc. Ease of processing workability and post-processing of products, and the effect of improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] Correspondingly, the preparation method of this nitrile rubber sealing material may further comprise the steps:

[0021] Add 100 parts of nitrile rubber to the internal mixer, masticate for 45 to 150 seconds at a temperature of 20 to 50 ° C, and then add the above-mentioned parts by mass of zinc oxide, stearic acid, anti-aging agent, and anti-friction agent for mixing After mixing for 30-60 seconds, add 1 / 2 carbon black (that is, 1 / 2 of the total mass of carbon black) and continue mixing. After mixing for 2-5 minutes, add the remaining carbon black and TP-95 and continue mixing. After refining for 1 to 3 minutes, discharge the rubber at a temperature of 110 to 130°C, knead on the turning machine for 60 to 100 seconds, and cool down the next piece to obtain a section of mixed rubber; a section of mixed rubber is parked at room temperature for 8-10 hours Finally, add the mixed rubber to the wrapping roll on the open mill, add the accelerator and mix for 3 to 5 minutes, an...

Embodiment 1

[0029] A cold-resistant and wear-resistant nitrile rubber sealing material, its formula is as follows:

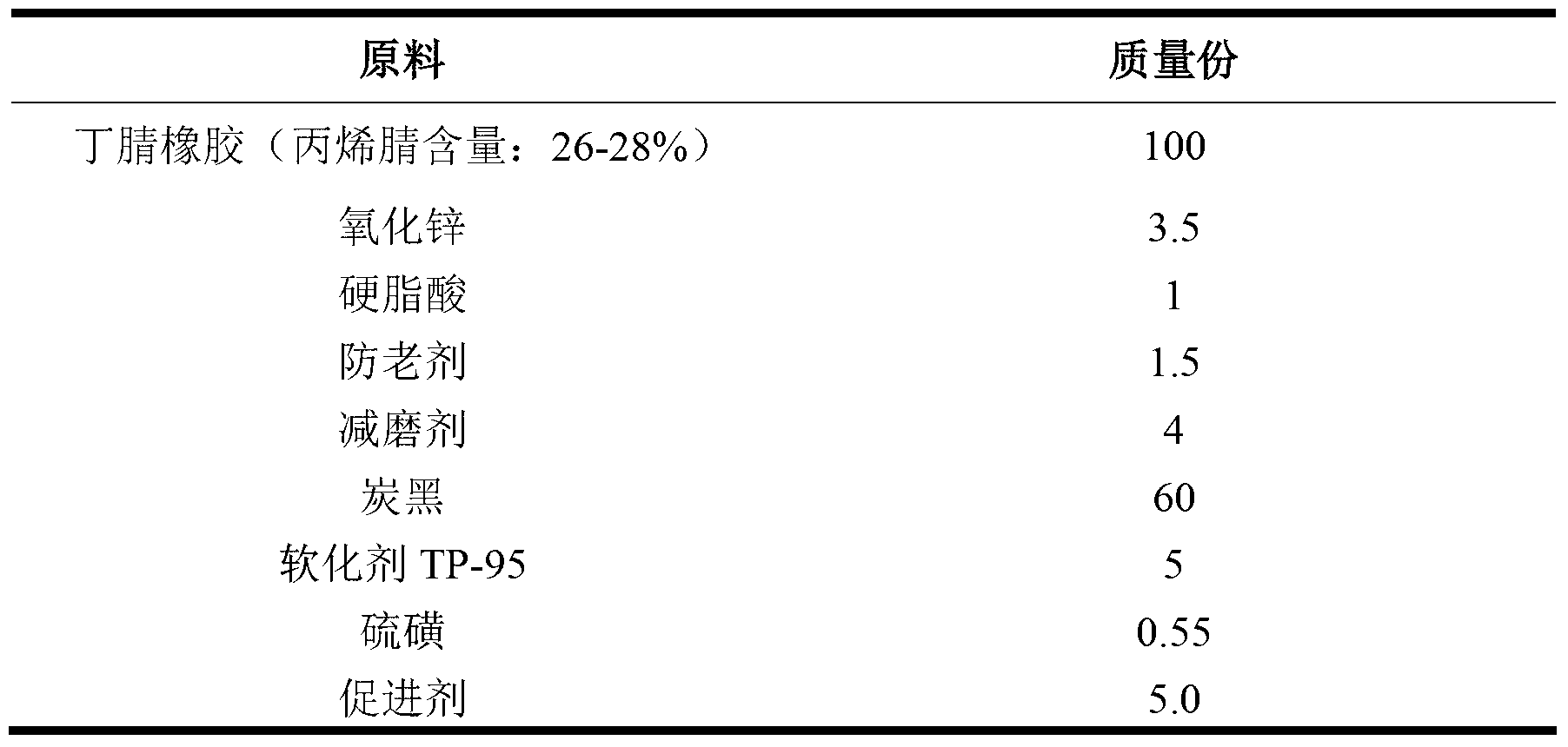

[0030] Table 1: Formula composition of cold-resistant and wear-resistant nitrile rubber sealing material

[0031]

[0032] Antiaging agent described in embodiment 1 is made up of 1.0 parts of antiaging agent RD and 0.5 part of antiaging agent MB; Described antifriction agent is oleic acid amide; Described carbon black is made up of 30 parts of carbon black N33030 and carbon black N77430 Part composition; The accelerator is composed of 1.8 parts of accelerator TT, 1.0 parts of accelerator CZ and 2.2 parts of accelerator DM.

Embodiment 2

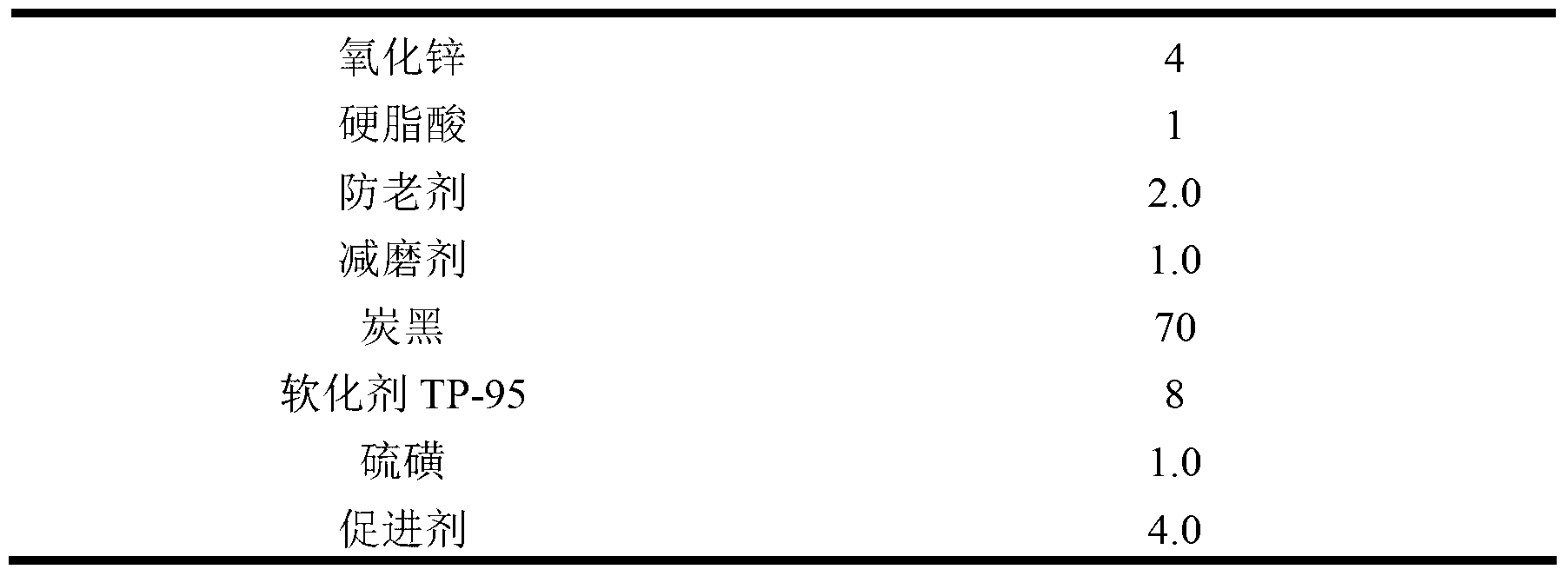

[0034] A cold-resistant and wear-resistant nitrile rubber sealing material, its formula is as follows:

[0035] Table 2: Formula composition of cold-resistant and wear-resistant nitrile rubber sealing material

[0036]

[0037]

[0038] Antiaging agent described in embodiment 2 is made up of 1.0 parts of antiaging agent RD, 0.5 part of antiaging agent 4010NA and 0.5 part of antiaging agent MB; Described antifriction agent is erucamide; Described carbon black is made of carbon 20 parts of black N220 and 50 parts of carbon black N330; the accelerator consists of 2.0 parts of accelerator TT and 2.0 parts of accelerator CZ.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com