Coil coating and production method thereof

A technology of coil coating and epoxy resin, which is applied in the field of coatings, can solve the problems of poor corrosion resistance, weather resistance and durability, etc., and achieve the effects of good scratch resistance, excellent adhesion, and strong acid and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

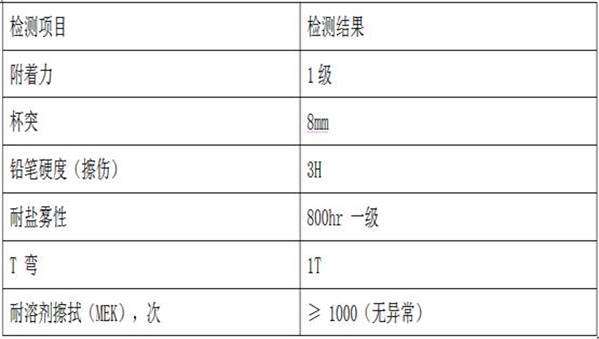

Image

Examples

Embodiment 1

[0047] The coil coating comprises the following raw materials in parts by weight: 80 parts of epoxy resin; 50 parts of acrylic resin; 15 parts of polyvinylidene fluoride; 3 parts of garnet; 10 parts of glass fiber; 5 parts of titanium dioxide; 5 parts of zinc oxide; 0.5 part of auxiliary agent.

[0048] The garnet is a garnet filter material with a particle size of 200 mesh; the glass fiber is silk powder with a particle size of 26 μm; the leveling agent is a leveling agent deggusa1484; the coupling agent is a three-tert Butoxyvinylsilane and γ-(β-aminoethyl)aminopropyltrimethoxysilane are mixed in a weight ratio of 1:1.

[0049] The production method of coil coating, the steps are as follows:

[0050] Add epoxy resin, acrylic resin, polyvinylidene fluoride and dispersant to the reactor, stir at 1100r / min for 21 minutes; then put titanium dioxide and zinc oxide into the reactor, stir at 580r / min, stir for 20min ; Put the glass fiber into it, heat it in a water bath at 45°C, ...

Embodiment 2

[0052] Coil coating, comprising the following raw materials in parts by weight: 90 parts of epoxy resin; 60 parts of acrylic resin; 17 parts of polyvinylidene fluoride; 4 parts of garnet; 12 parts of glass fiber; 6 parts of titanium dioxide; 6 parts of zinc oxide; 1 part of auxiliary agent.

[0053] The garnet is a garnet filter material with a particle size of 300 mesh; the glass fiber is silk powder with a particle size of 27 μm; the leveling agent is a mixture of leveling agents deggusa1484 and EFKA3777; the coupling agent, Mix any two of γ-methacryloxypropyl tris(β-methoxyethoxy)silane and γ-isocyanatopropyl trimethoxysilane in a weight ratio of 1:1.

[0054] The production method of coil coating, the steps are as follows:

[0055] Add epoxy resin, acrylic resin, polyvinylidene fluoride and dispersant to the reactor, stir at 1200r / min for 25 minutes; then put titanium dioxide and zinc oxide into the reactor, stir at 620r / min, stir for 50min ; Put the glass fiber into it,...

Embodiment 3

[0057] The coil coating comprises the following raw materials in parts by weight: 100 parts of epoxy resin; 65 parts of acrylic resin; 17 parts of polyvinylidene fluoride; 4 parts of garnet; 13 parts of glass fiber; 8 parts of titanium dioxide; 8 parts of zinc oxide; 1.5 parts of auxiliary agent.

[0058] The garnet is a garnet filter material with a particle size of 400 mesh; the glass fiber is silk powder with a particle size of 28 μm; the leveling agent is a mixture of leveling agents deggusa1484, EFKA3777 and EFKA3239; the coupling The agent is tri-tert-butoxyvinylsilane and γ-methacryloxypropyltris(β-methoxyethoxy)silane mixed in a weight ratio of 1:1.

[0059] The production method of coil coating, the steps are as follows:

[0060] Add epoxy resin, acrylic resin, polyvinylidene fluoride and dispersant to the reactor, stir at 1100r / min for 25 minutes; then put titanium dioxide and zinc oxide into the reactor, stir at 620r / min, stir for 50min ; Put the glass fiber into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com