A room temperature curing high temperature resistant silicone rubber coating, preparation method and application

A silicone rubber, room temperature curing technology, used in coatings, fire-resistant coatings, etc., can solve the problems of brittle application limitations, poor mechanical properties, loss of mechanical strength, molding process performance, etc., to simplify formula design and meet application requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The preparation method of above-mentioned polysilazane, described method comprises the steps:

[0055] (1) Drying the solvent, ammonia gas, difunctional chlorosilane and trifunctional chlorosilane, and drying the reaction device;

[0056] (2) Add the dried solvent into the reaction device through a metering pump, add the dried difunctional chlorosilane and trifunctional chlorosilane into the reaction device through a metering pump respectively, and pass the dried ammonia through a mass flow meter. Enter under the liquid level of reaction device, carry out ammonolysis reaction;

[0057] (3) Put the "slurry" system containing a large amount of ammonium chloride after the reaction into the filter device through the mortar pump, filter and wash the filter residue with a solvent, and collect the filtrate;

[0058] (4) The filtrate containing the polysilazane product is introduced into a thin-film evaporator with continuous distillation function through a material transfer p...

preparation example 1

[0069] 600L of petroleum ether (boiling point 30-60°C) was dried through molecular sieves and added to a 1000L reactor through a metering pump, and 100kg of dimethyldichlorosilane and 100kg of methyltrichlorosilane were added to the reactor through the frequency control of the metering pump. Silane, start the stirring of the reactor at 5000rpm, control the temperature in the reactor at -20°C through a refrigerator, dry the ammonia gas through a molecular sieve, and then enter the reactor through mass flow meter control, and pass through 5 inlets arranged around the stirring shaft. The pores enter the reaction system in the form of microbubbles under the air pressure of 3MPa. 10kg of ceramic balls are placed in the reactor to break the ammonium chloride p-dimethyldichlorosilane and methyltrichlorosilane produced in situ. And the resulting polymethylsilazane coating. After 24 hours, no ammonia gas can be detected in the tail gas, and the reaction system stops passing ammonia. Du...

Embodiment 1

[0071] Component A of room temperature curing high temperature resistant silicone rubber thermal protective coating (the following parts represent parts by mass):

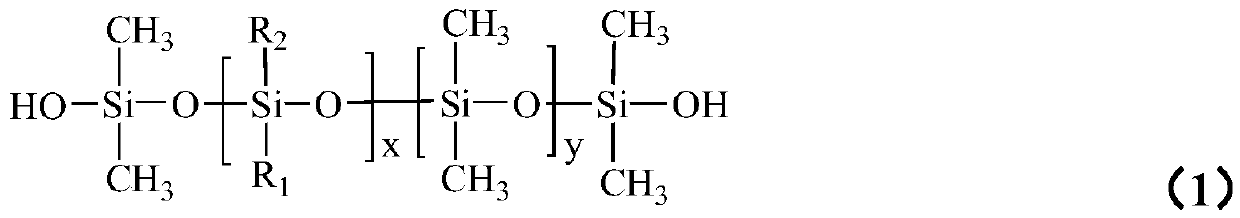

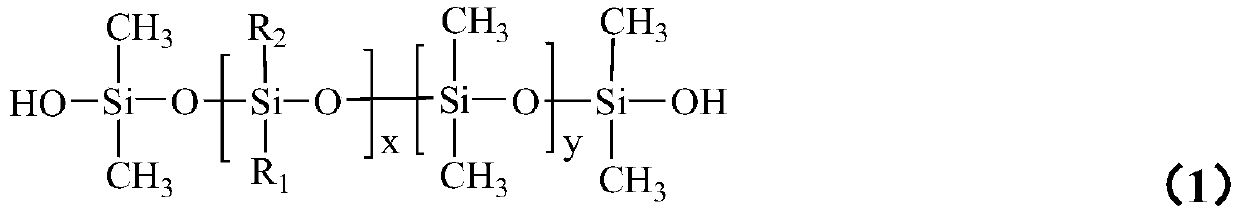

[0072] Methylpolysiloxane (the brand is 107 silicone rubber, the manufacturer is Xinghuo silicone, the viscosity is 7000cps, that is, R in the above formula (1) 1 and R 2 At the same time, 100 parts are selected from methyl), 25 parts of precipitated white carbon black (the brand is 779, the manufacturer is Fujian Zhengsheng), 6 parts of ferric oxide with micro-nano structure, and 10 parts of tin oxide with micro-nano structure , 10 parts of glass hollow microspheres with a hollow structure, 10 parts of glass fibers with a micro-nano structure, and 10 parts of cyclohexane.

[0073] The coating preparation process is as follows:

[0074] (1) Purify the used methylpolysiloxane using a molecular distillation device at a vacuum degree of 50Pa and a temperature of 140°C, and the volatile content of the purified methyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com