Treatment method for wastewater after vanadium precipitation

A vanadium-precipitated waste water and treatment method technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of high COD in discharged waste water, failure to meet discharge standards, failure to meet standards Discharge and other issues, to achieve the effect of reducing the occupied area and investment scale, realizing the reuse of resources, and high efficiency of wastewater treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

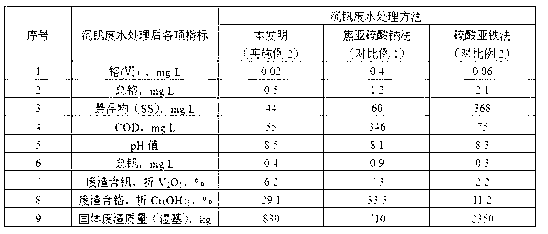

Embodiment 1

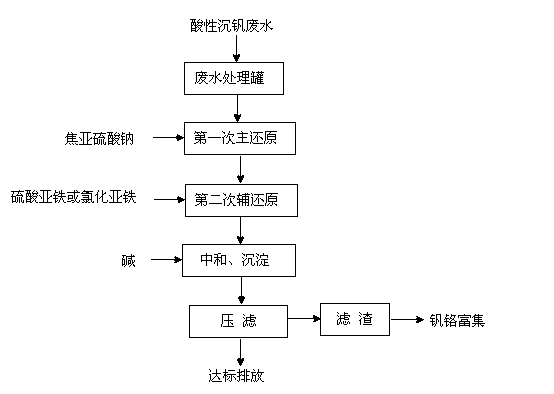

[0032] Such as figure 1 Shown, the concrete steps of the treatment method of acidic vanadium precipitation wastewater are as follows:

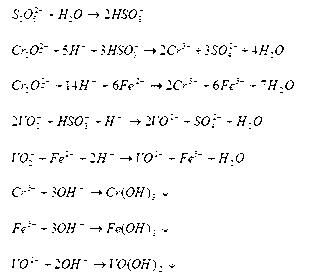

[0033] (1) put 20m 3The acidic vanadium precipitation wastewater is injected into the wastewater treatment tank, and the concentration of chromium (Ⅵ) in the vanadium precipitation wastewater is detected to be 325mg / L, and the concentration of vanadium (Ⅴ) is 140mg / L. The amount is 2.0 times the sum of the mass of chromium (Ⅵ) and vanadium (Ⅴ) in the vanadium precipitation wastewater) to carry out the main reduction reaction, the temperature of the first main reduction reaction is 40℃~45℃, and the reaction time is 20min, so that the Chromium (Ⅵ) and trace vanadium (Ⅴ) are reduced to chromium (Ⅲ) and vanadium (Ⅳ) respectively;

[0034] (2) After detecting the concentration of chromium (Ⅵ) in the vanadium precipitation wastewater after the first reduction is 101 mg / L, and the concentration of vanadium (Ⅴ) is 38 mg / L, add 44.5 kg of auxiliary r...

Embodiment 2

[0037] (1) will 30m 3 The acidic vanadium precipitation wastewater was injected into the wastewater treatment tank, and the concentration of chromium (Ⅵ) in the vanadium precipitation wastewater was detected to be 1302 mg / L, and the concentration of vanadium (Ⅴ) was 171 mg / L, and 141.4 kg of solid sodium metabisulfite (sodium metabisulfite) as the main reducing agent was added to the wastewater treatment tank. The amount added is 3.2 times the sum of the mass of chromium (Ⅵ) and vanadium (Ⅴ) in the vanadium precipitation wastewater), the temperature of the first main reduction reaction is 85°C to 90°C, and the reaction time is 60min, so that the chromium (Ⅵ) in the vanadium precipitation wastewater ) and trace vanadium (Ⅴ) are reduced to chromium (Ⅲ) and vanadium (Ⅳ) respectively;

[0038] (2) After detecting the concentration of 50 mg / L of chromium (Ⅵ) and 21 mg / L of vanadium (Ⅴ) in the vanadium precipitation wastewater after the first reduction, add 55.4 kg of auxiliary redu...

Embodiment 3

[0041] (1) will 40m 3 The acidic vanadium precipitation wastewater was injected into the wastewater treatment tank, and the concentration of chromium (Ⅵ) in the vanadium precipitation wastewater was detected to be 876 mg / L, and the concentration of vanadium (Ⅴ) was 182 mg / L. Then, 101.6 kg of solid sodium metabisulfite (sodium metabisulfite), the main reducing agent, was added to the wastewater treatment tank. The amount added is 2.4 times the sum of the mass of chromium (Ⅵ) and vanadium (Ⅴ) in the vanadium precipitation wastewater), the temperature of the first main reduction reaction is 55°C-60°C, and the reaction time is 25min, so that the chromium (Ⅵ) in the vanadium precipitation wastewater ) and trace vanadium (Ⅴ) are reduced to chromium (Ⅲ) and vanadium (Ⅳ) respectively;

[0042] (2) After detecting the concentration of chromium (Ⅵ) in the vanadium precipitation wastewater after the first reduction is 47mg / L, and the concentration of vanadium (Ⅴ) is 24mg / L, add 51.1kg o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com