Method of blasting multiple layers or levels of rock

A rock formation and blasting hole technology, applied in blasting, earth-moving drilling, surface mining, etc., can solve problems such as unproven substantial improvements, and achieve the effect of reducing possibility and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0070] Referring to the accompanying drawings, various implementations of the blasting method of the present invention are only introduced by way of example, wherein:

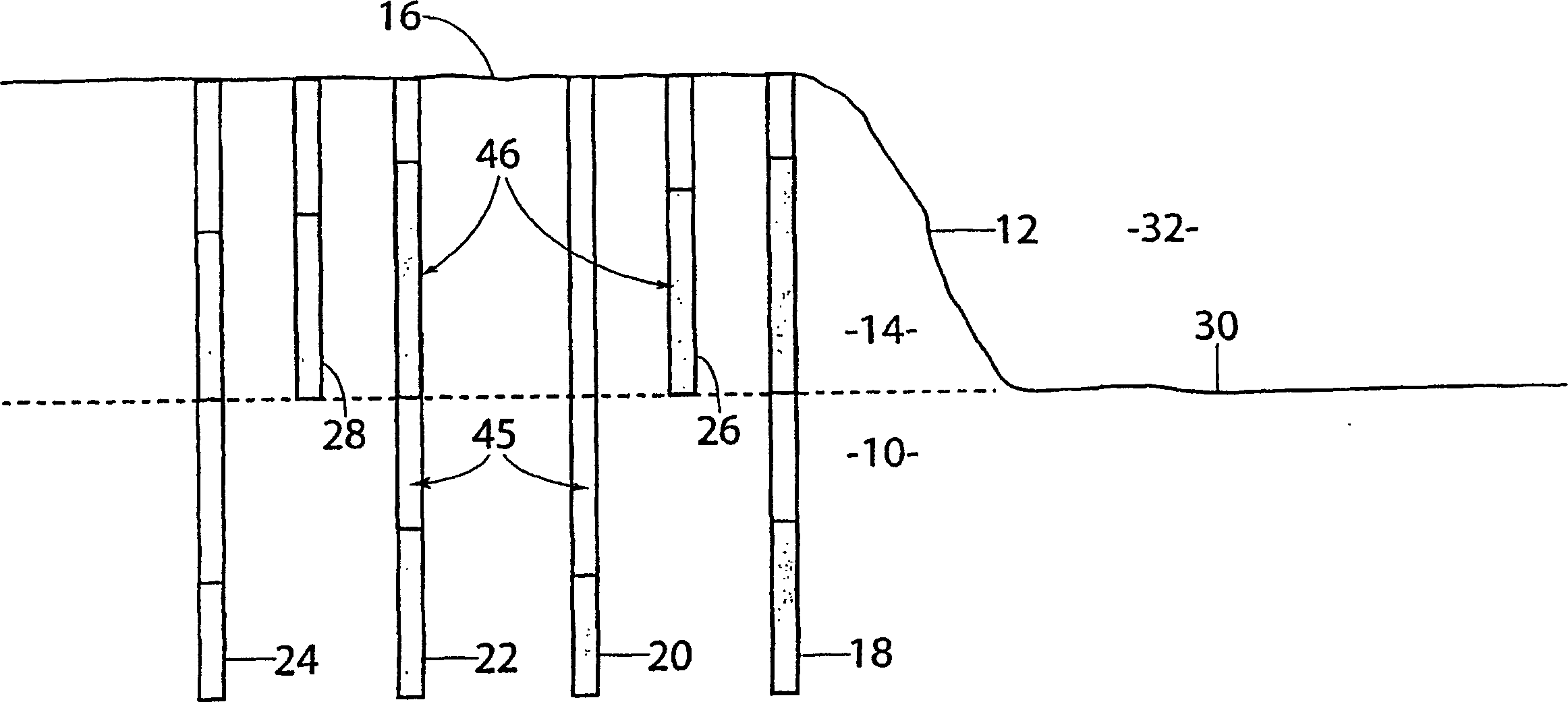

[0071] figure 1 Shown is the general idea of the inventive method;

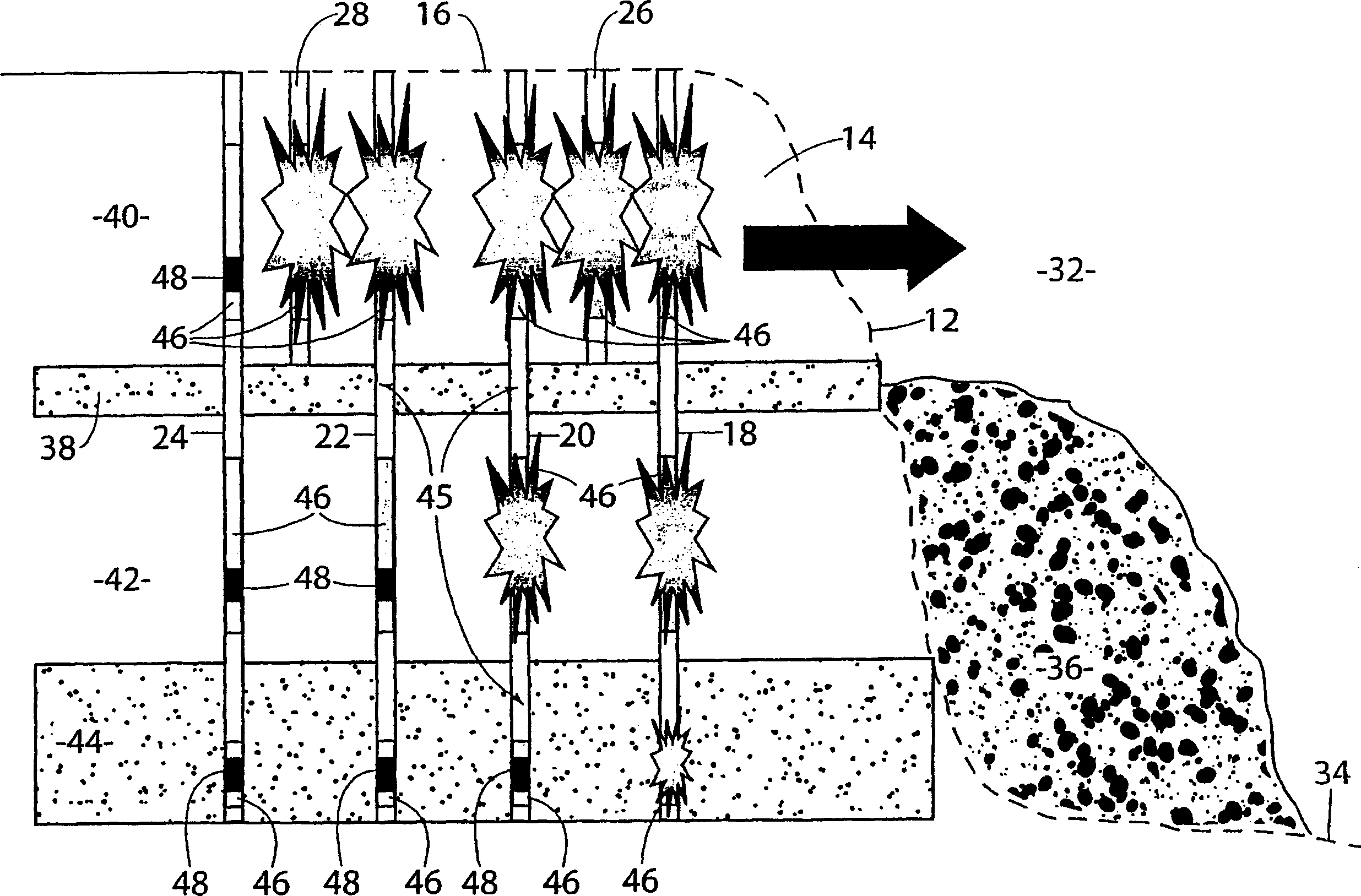

[0072] figure 2 Shown is a first specific embodiment of the method of the invention;

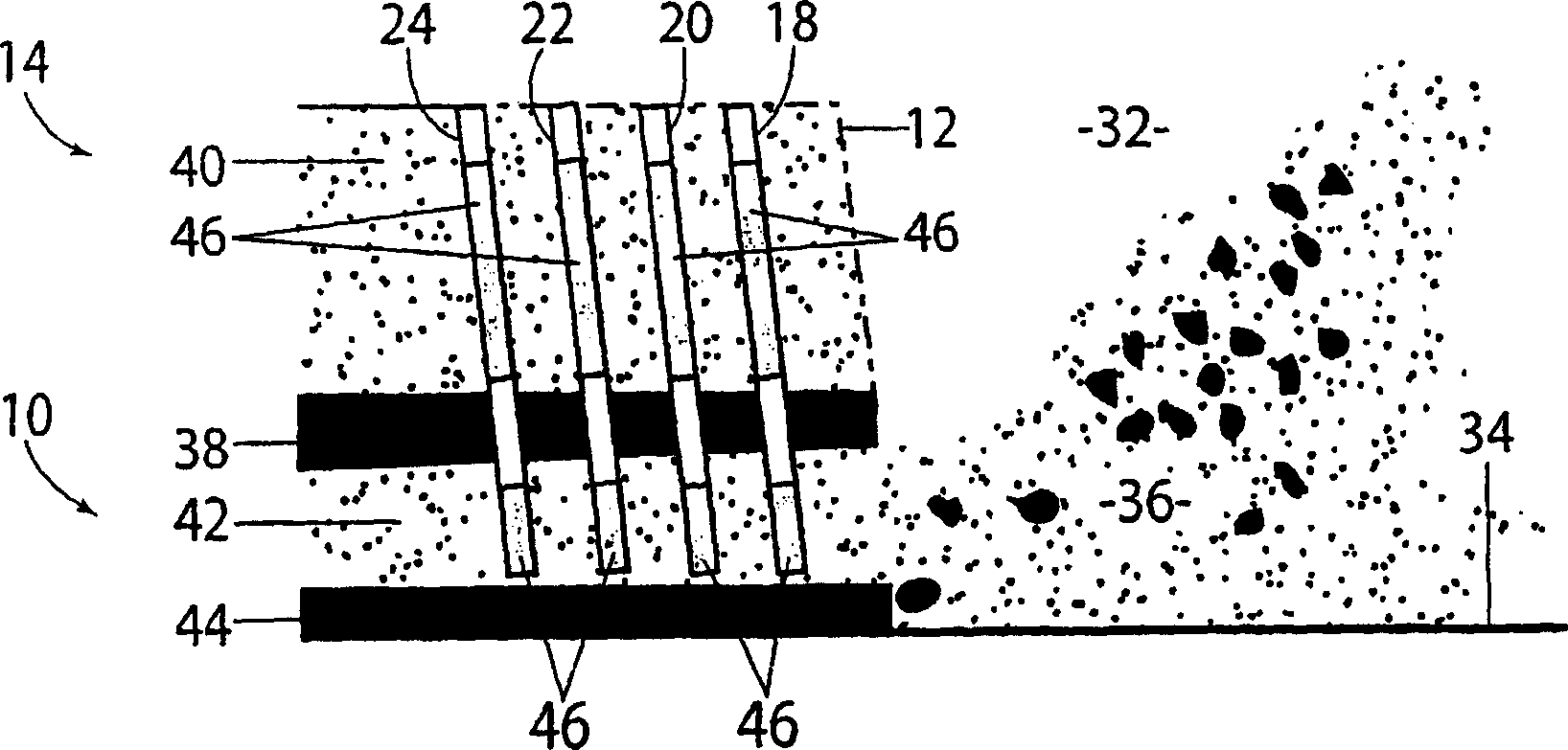

[0073] image 3 Shown is a second particular embodiment of the method of the invention;

[0074] Figure 4 Shown is a third specific embodiment of the method of the invention;

[0075] Figure 5 Shown is a fourth particular embodiment of the method of the invention;

[0076] Figure 6a and 6b shown in accordance with Figure 5 Plan and cross-sectional views of the blasts described in examples of the illustrated embodiments;

[0077] Figure 7 Shown is a kind of blasting method of the present invention, and it has obtained differential crushing result;

[0078] Figure 8 is similar to Figure 6a , but belongs to another blasting method of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com