Vertical steel slag pressure hot-disintegration still kettle and slag processing method

An autoclave and hot stuffy technology, applied in vertical steel slag autoclave and treatment, casting residual slag treatment, converter steel slag field, can solve the problems of low steel slag treatment rate, equipment wear, equipment failure rate, etc. , to achieve the effect of improving the penetration rate, promoting rapid progress and good pulverization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

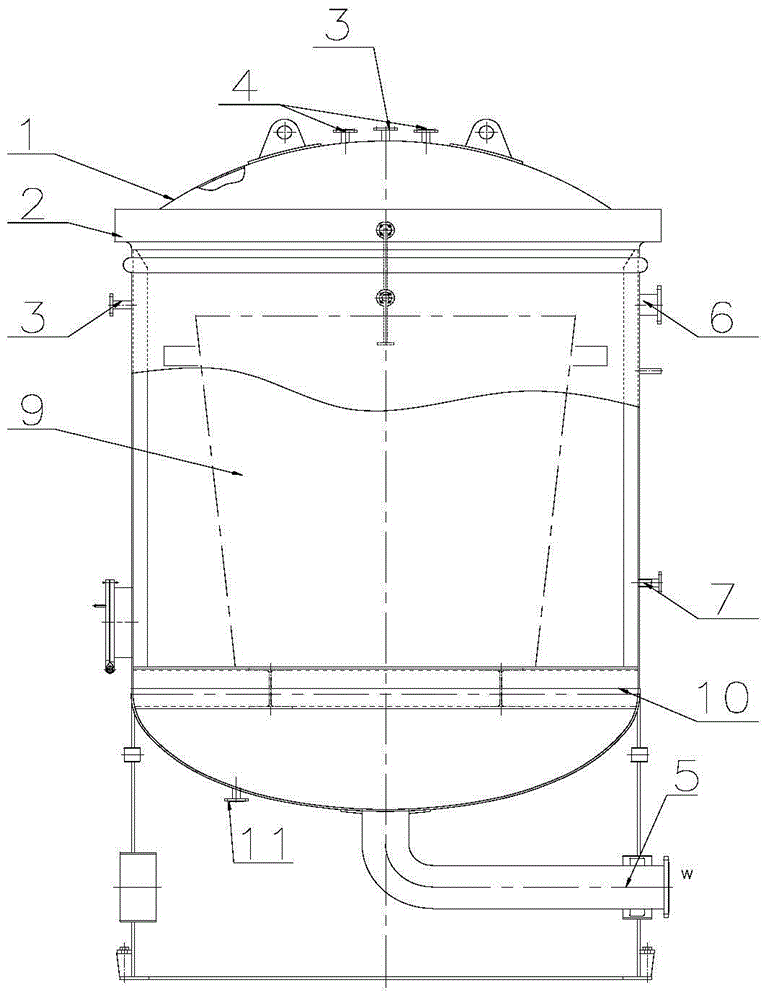

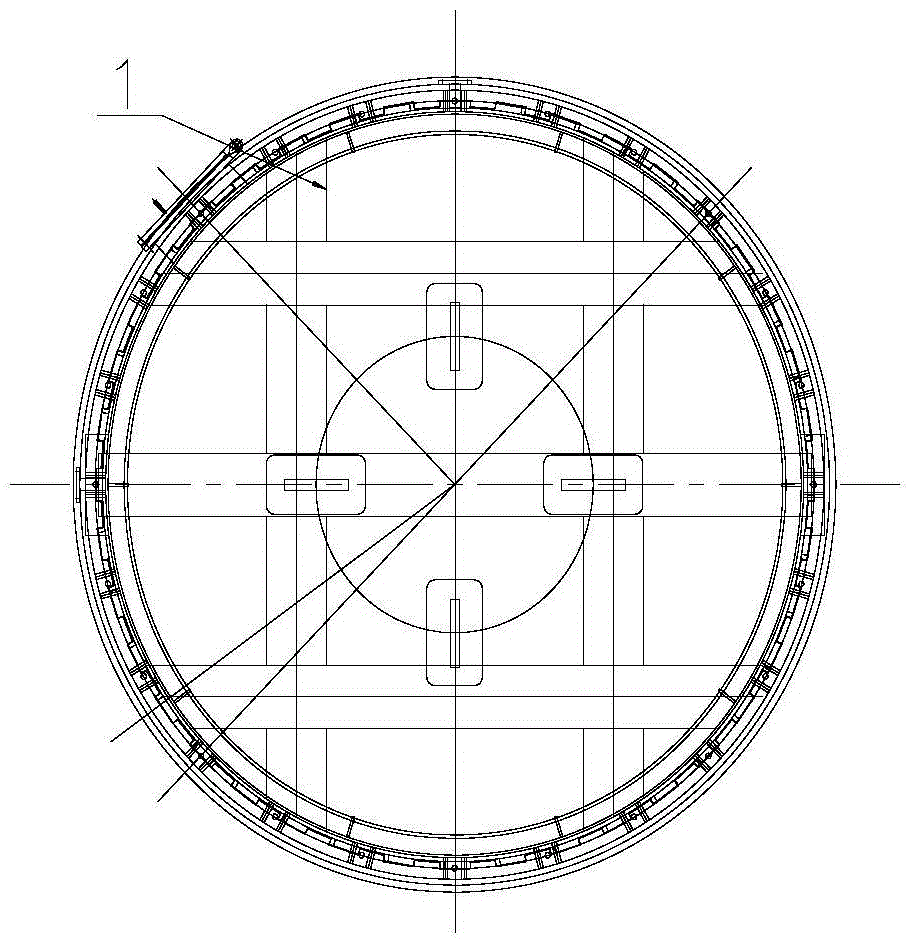

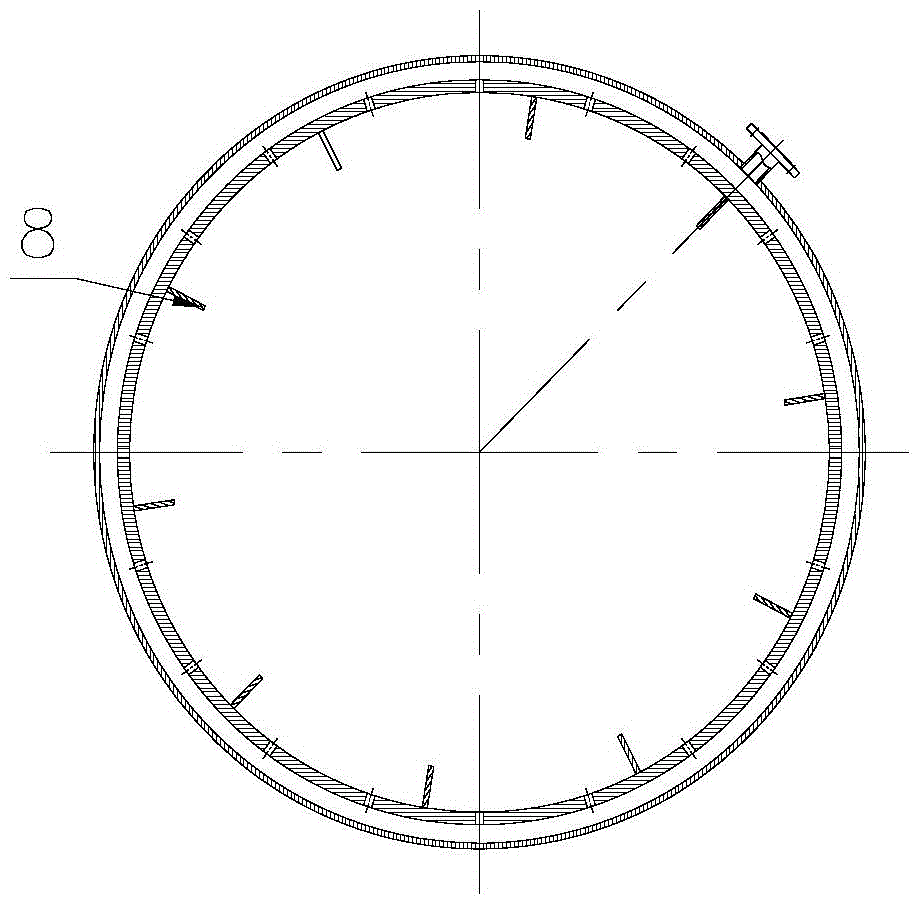

[0025] Such as figure 1 , 2 , 3 is a structural schematic diagram of a steel slag waste heat pressure self-decomposition treatment device of the present invention, including a top cover 1, a cylinder body 2, a water spray device 3, a safety device 4, a drainage device 5, an exhaust pressure stabilizing device 6, a safety monitoring Device 7, guide device 8, slag tank 9, slag tank support 10, gas replacement device 11; wherein the safety monitoring device includes a pressure detection device, a temperature detection device, and a gas composition and concentration detection device.

[0026] The autoclave 2 is a vertical cylindrical pressure vessel, the top of which is provided with a top cover 1; the cylinder body 2 and the top cover 1 are used to form a closed space, so that the steel slag can automatically Depowdering.

[0027] The water spraying device 3 is arranged circularly along the inner wall of the top cover 1, and the water spraying device 3 is used to spray water to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com