Gas sensor test system for dynamic and static gas distribution dual purposes

A technology of gas sensor and static gas distribution, applied in standard gas analyzers, analyzing gas mixtures, instruments, etc., can solve the problems of single dynamic or static gas sensitivity test method of gas sensor test system, affecting the performance of gas sensor, etc., to achieve Performance calibration and testing, solving uncontrollable air humidity, and avoiding the effect of gas accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] The invention relates to the test of the dynamic and static dual-purpose gas test system under static liquid vapor.

[0072] The realization of static mixed gas distribution is as follows:

[0073] According to the gas state equation PV=nRT (1)

[0074] Where P is the gas pressure, V is the gas volume, n is the number of moles of gas molecules, R is the gas constant, and T is the gas temperature. For a certain concentration of gas the volume is:

[0075] V=C ppm ×V C (2)

[0076] where C ppm is the gas concentration, V C is the volume of the test chamber.

[0077] For an organic liquid, its volume V C The relationship between and the number of moles n is:

[0078] V L =m / ρ=nM / ρ (3)

[0079] Where M is the molecular weight, ρ is the mass density of the organic liquid, and m is the mass of the organic liquid.

[0080] Thus the organic liquid volume V is obtained C and its vaporized concentration C ppm The relationship between is:

[0081] V L = P C ppm ...

Embodiment 2

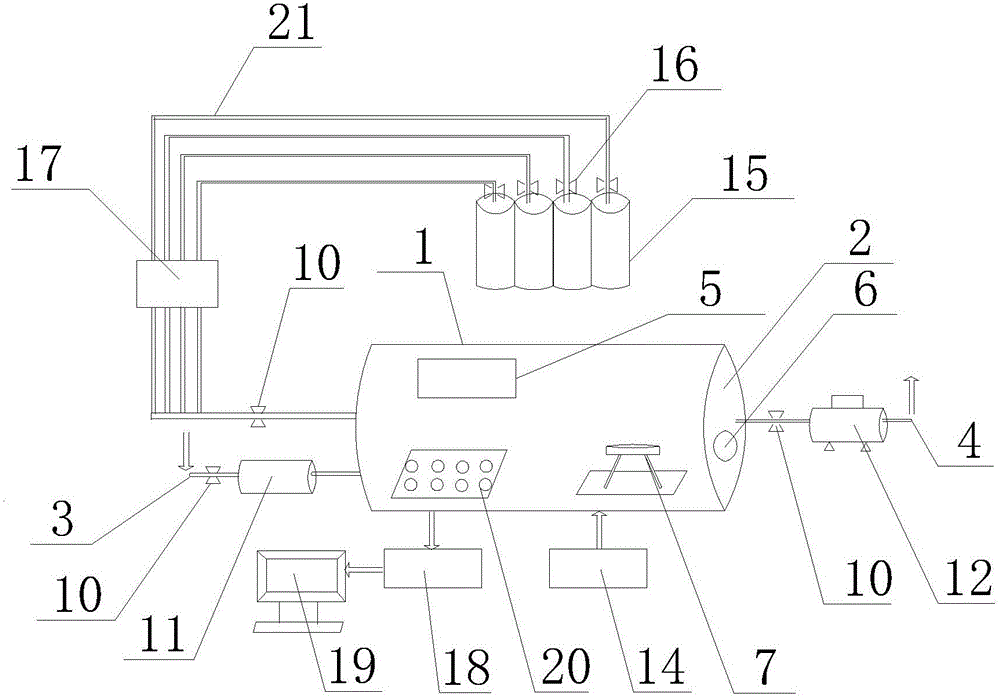

[0092] The present invention relates to the test of the dynamic and static dual-purpose gas sensor under dynamic gas.

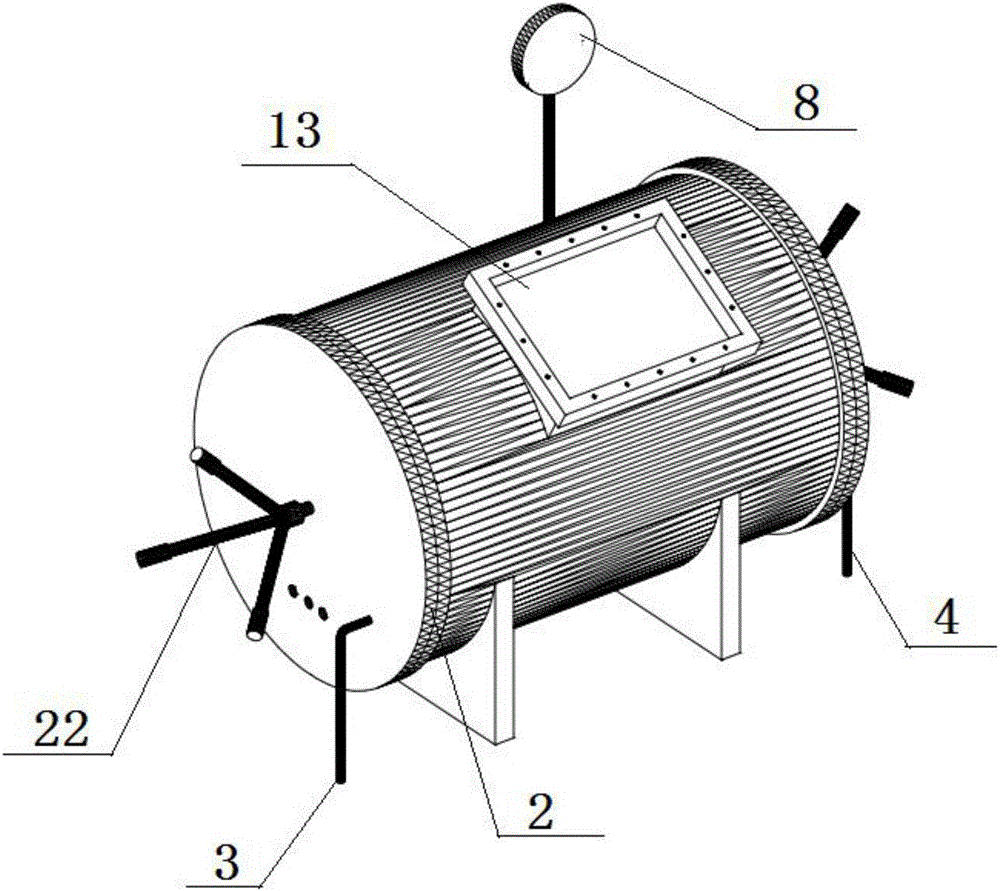

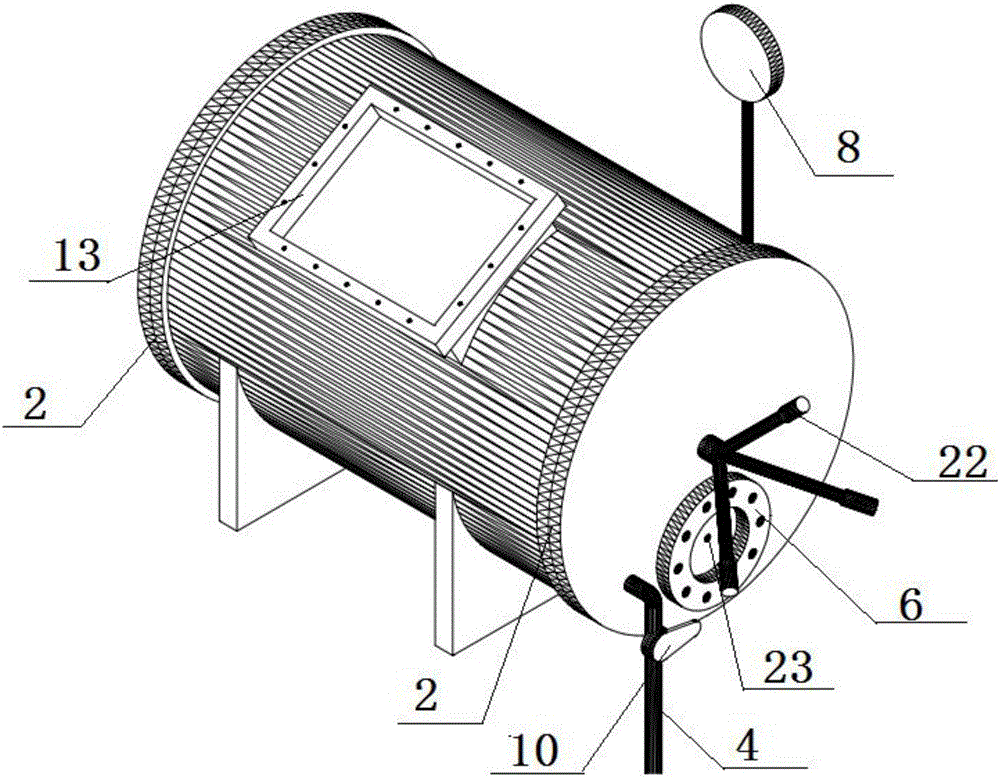

[0093] The gas sensor to be tested is installed on the sensor base 20 in the test cavity, and its output signal is connected to the external data collector 18 through the wire and the aviation connector 9 on the test cavity 1, and the data output of the data collector 18 is The terminal is connected with the data signal input terminal of the computer 19, and the computer 19 completes the data collection and storage.

[0094] Tighten the airtight hatches at both ends of the test chamber 1 through three handles 22 to make it hermetically closed, close the shut-off valve 10 on the air inlet pipeline 3, and open the shut-off valve 10 on the air outlet pipeline 4. Open the shut-off valve 10 in the dynamic gas supply unit, open the pressure reducing valve 16 in the dynamic gas supply unit and adjust the pressure simultaneously, make the gas in the gas cylinder 15 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com