Method for detecting flatness of large-scale flange

A flatness detection, large flange technology, applied in measuring devices, instruments, optical devices, etc., can solve the problems of loss of accuracy, lack of inspection independence, and difficulty in inspection results being less than 1mm, and achieve high acquisition efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

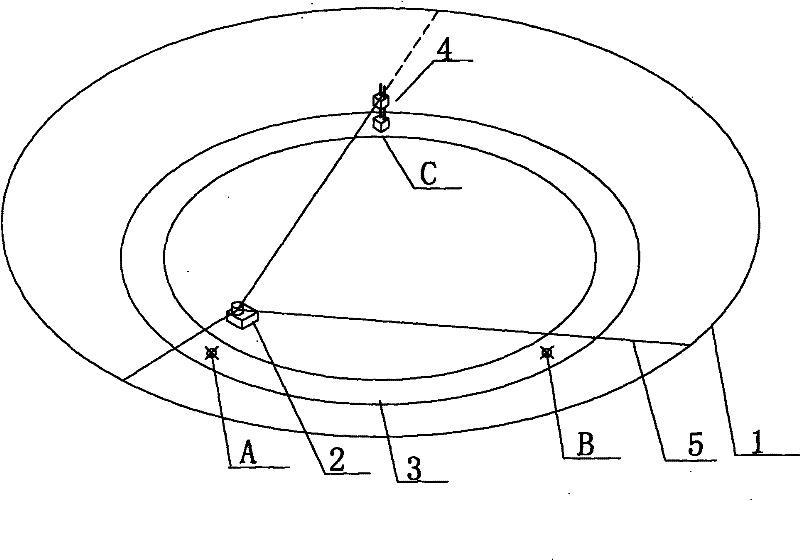

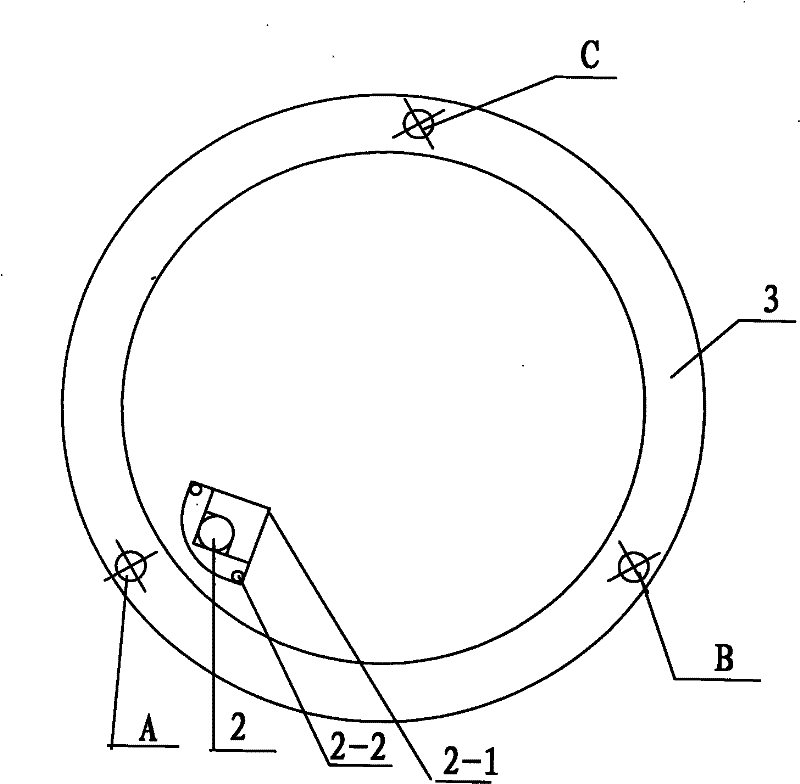

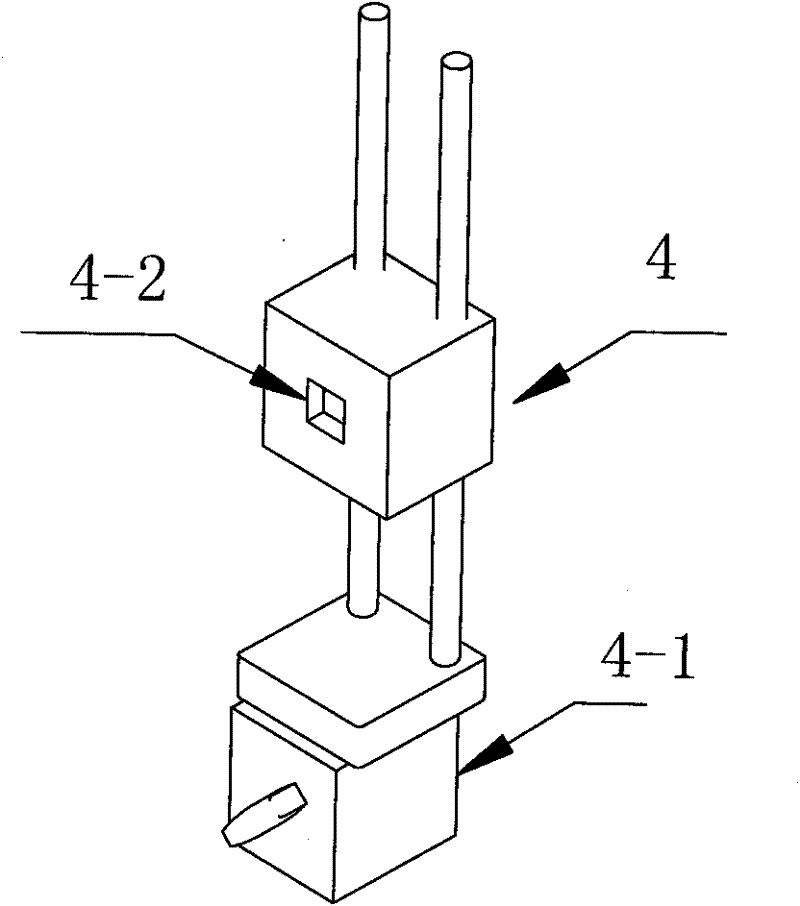

[0036] like Figure 1-Figure 4 Shown: a large-scale flange flatness detection method, the detection equipment used is a set of laser leveling equipment, the laser leveling equipment has a laser emitter that can rotate 360 degrees, from the emitter can be obtained A laser beam sweeps the surface plane, and another detector can indicate the position of the center of the laser beam, and the reading accuracy can reach 0.001mm. It includes the following steps:

[0037] A. Select measurement reference points: select three points distributed as uniformly as possible on the circumference of the flange surface 3 to be measured as measurement reference points, and mark them as reference points A, B, and C in turn for re-in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com