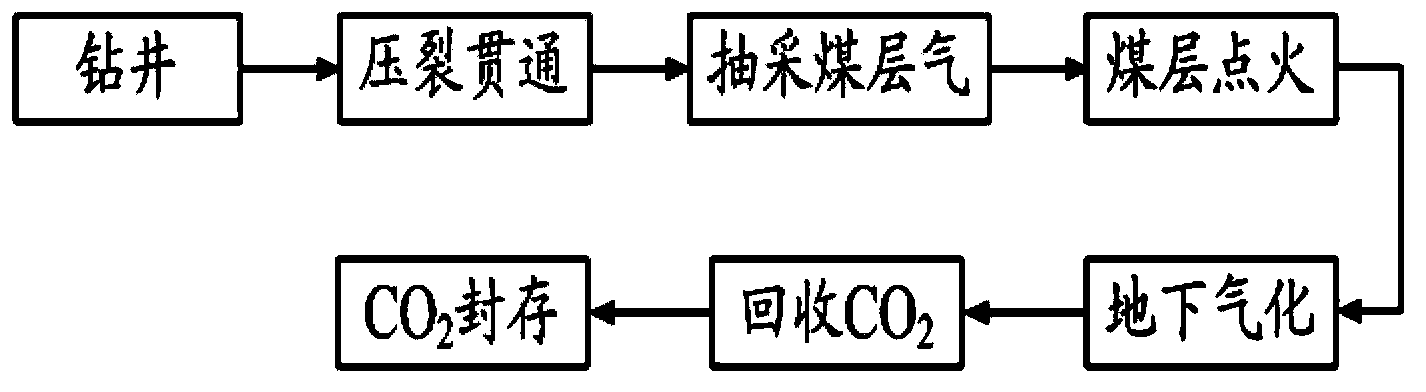

Method for extracting coalbed methane and coal together

A technology of coalbed methane and co-mining, which is applied in the directions of coal gasification, drilling equipment and methods, and production fluids, etc., can solve the problems of not considering recovery and utilization, decrease of coalbed methane production, increase of investment cost, etc. The effect of composition, improving recovery rate and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

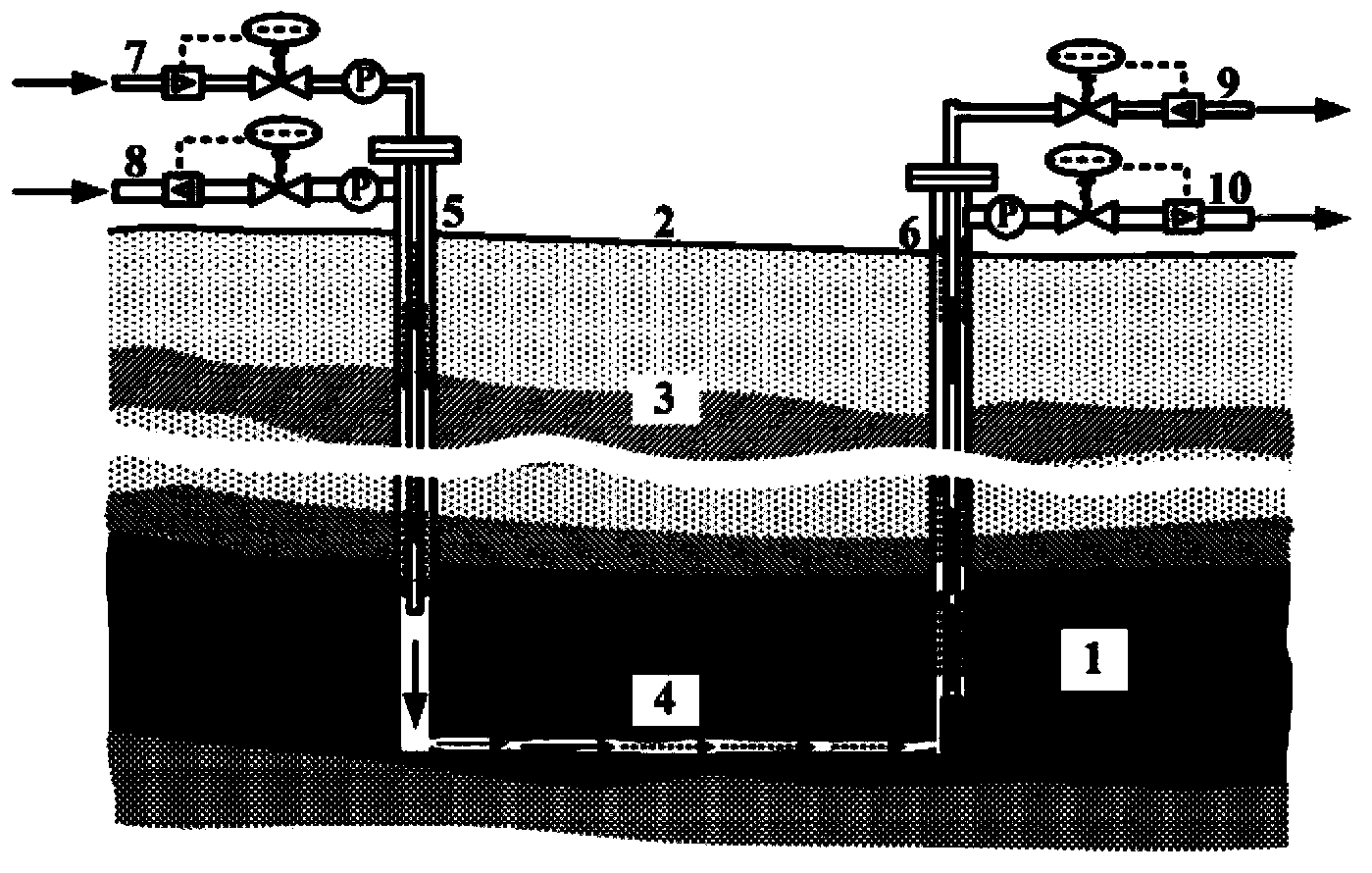

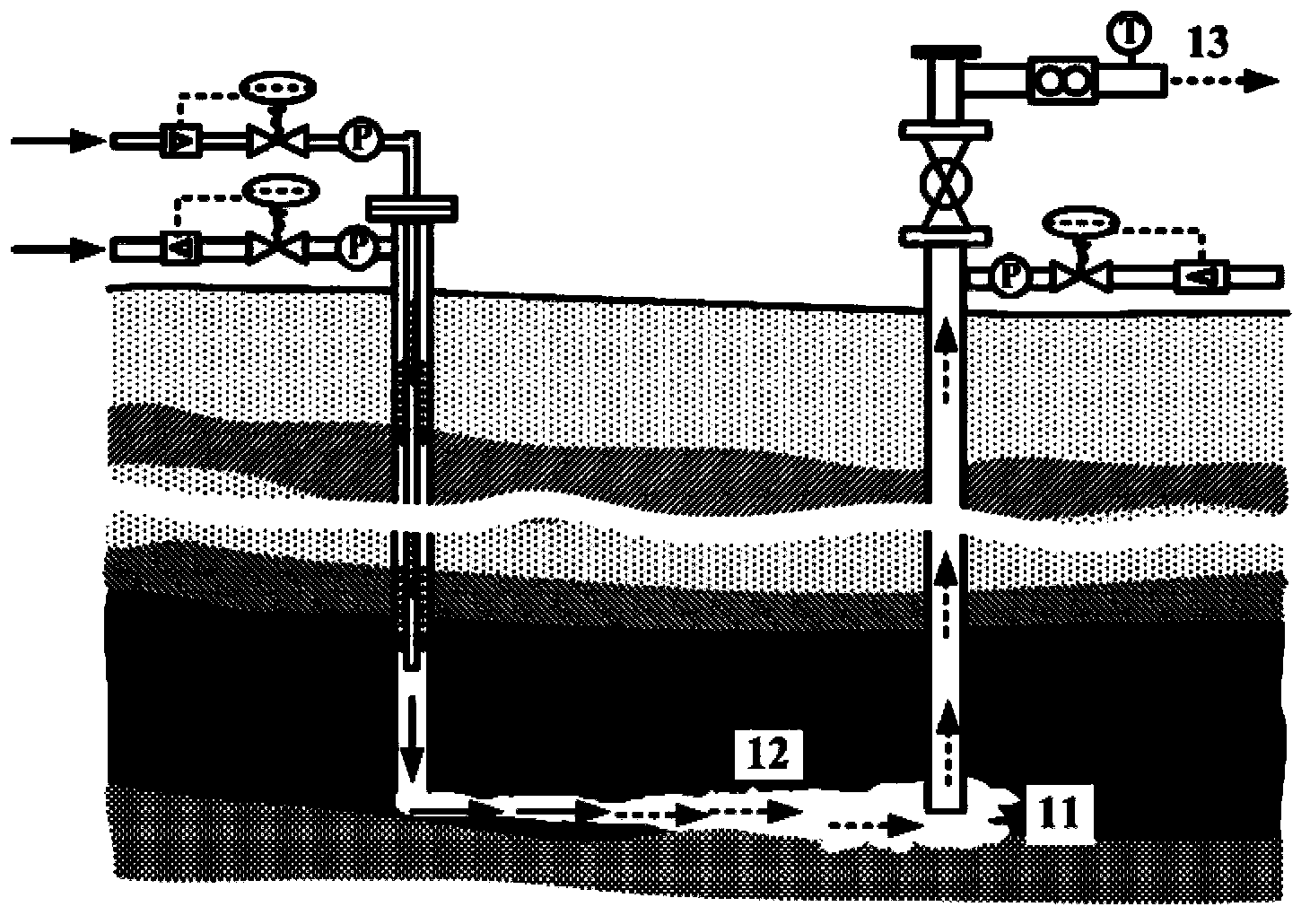

[0100] This example refers to figure 2 and image 3 to describe. figure 2 It is a schematic diagram of a coalbed methane and coal co-mining method according to the present invention, wherein the coal seam between the boreholes is fractured in a cold state and injected with CO 2 extraction of coalbed methane; and image 3 It is a schematic diagram of the coalbed methane and coal co-mining method, in which a fire zone is established to thermally process the fissures, expand them into gasification channels, and simultaneously displace the coalbed methane. Such as figure 2 and image 3 As shown, in this embodiment, the drill holes are set according to the scope of the proposed gasification coal seam, and the number of drill holes is determined by the coal seam reserves and the scale of gas production, but at least one air inlet and one air outlet should be included in order to realize the present invention. The way is as follows:

[0101] see figure 2 and image 3 Cons...

Embodiment 2

[0119] Example 2 Use the pinnate branch horizontal drilling technology to speed up the extraction speed of coalbed methane, and at the same time use the branch well technology to communicate the natural cracks and cleats of the coal seam to increase the exposed area of the coal seam, which is beneficial to the subsequent gasification process. This example refers to Figure 4 and Figure 5 to describe. Figure 4 It is a schematic diagram of a coalbed methane and coal co-mining method according to the present invention, wherein the coalbed methane is extracted by using the pinnate branch horizontal drilling technology; Figure 5 According to the schematic diagram of the coalbed methane and coal co-mining method, the specific implementation is as follows:

[0120] From the ground 2 through the overburden 3 to the coal seam 1 construction vertical borehole as the gas outlet borehole 6, in the construction of the air intake borehole 5 in a certain distance range (referring to em...

Embodiment 3

[0135] Embodiment 3 is basically the same as Embodiment 2, except that directional horizontal drilling technology is used to establish the channel for initial drainage and gas recovery, and the arrangement of horizontal wells 15 with a U-shaped structure is formed. The horizontal wells are perpendicular to the direction of the main fractures of the coal seam, and Use the vertical well, that is, the gas outlet borehole 6 to drain water, and the inlet borehole 5 to produce gas. After the initial extraction of coalbed methane is completed, a fire zone is established in the gas outlet borehole 6, and a thermal processing channel is started to displace the coalbed methane synchronously. To complete the coal bed gasification between the boreholes, this embodiment refers to Figure 6 and Figure 7 to describe. Figure 6 is a schematic diagram of a coalbed methane and coal co-mining method according to the present invention, wherein the directional horizontal drilling technology is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com