Method for pumping coalbed gas by heating coal bed

A technology for coalbed methane and coal seams, which is applied in the field of coalbed methane extraction by using group wells to connect and heat coal seams, can solve the problems of difficult separation technology, difficult industrial production and application, etc., and achieves effective coalbed methane extraction, increased pressure, The effect of increasing permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

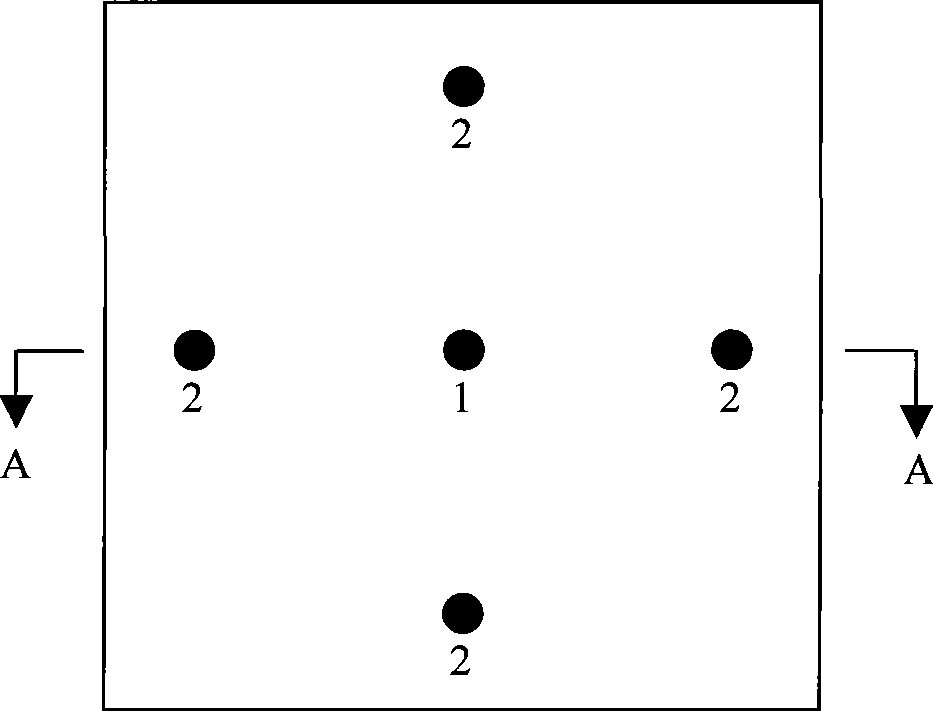

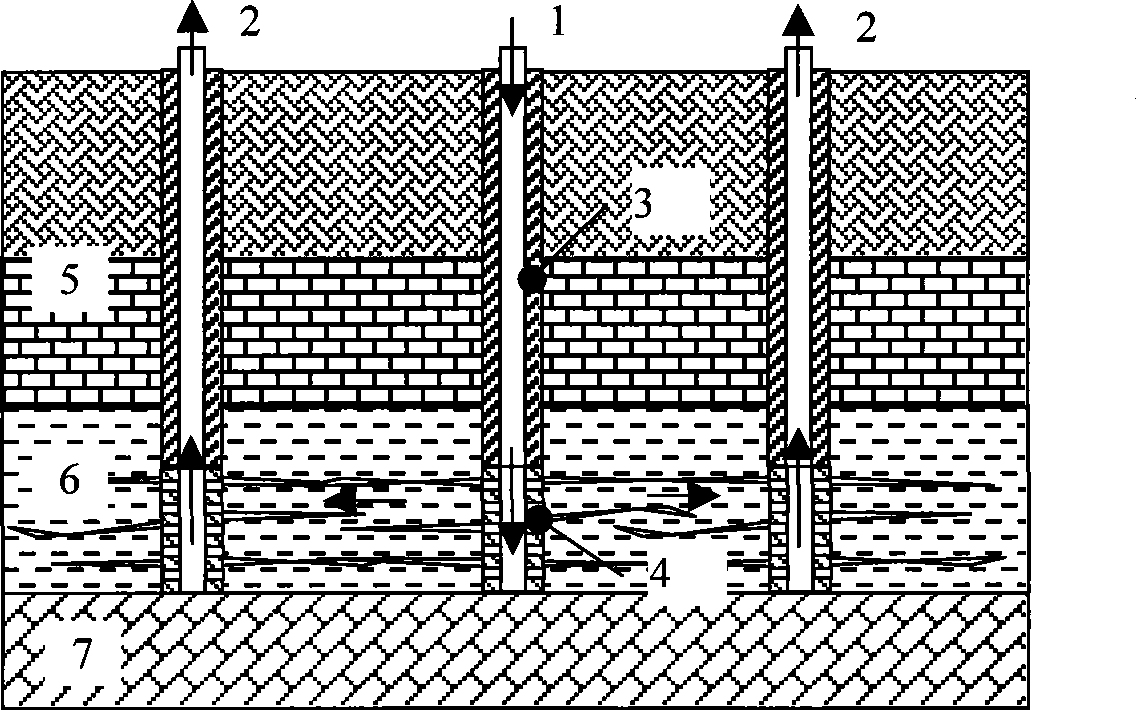

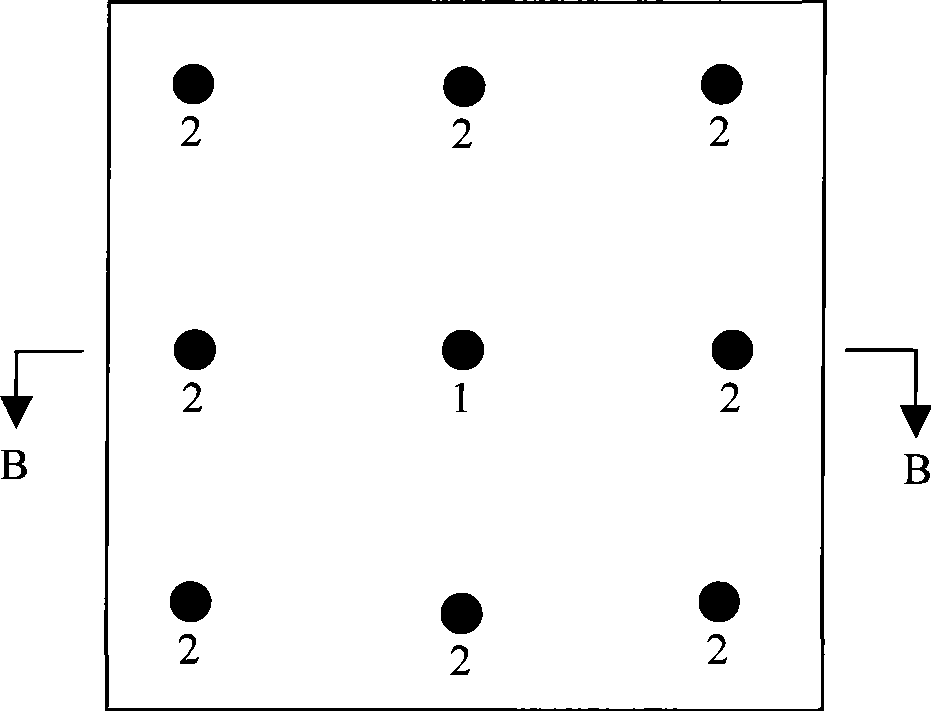

[0032] figure 1 , figure 2 The layout diagram of the ground vertical drilling well pattern of the present invention is given. As shown in the figure, select a suitable well spacing of 500m on the ground, determine the well location, implement vertical drilling into the coal seam, and arrange the well pattern. The well pattern consists of five wells including one heat source injection well 1 and four gas production wells 2 .

[0033] After the vertical drilling enters the coal seam 6, the screen casing 4 is lowered in the coal seam section, and the thermal insulation casing 3 is lowered in the 5th section of the overlying strata on the coal seam roof above the coal seam, and cementing is carried out according to the specification requirements.

[0034] After all the wells are completed and cemented, at least one heat source injection well 1 is selected, and the rest are gas production wells 2 . According to the size of the coal seam permeability, it is determined whether th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com