Construction method for enhancing extraction effect of ground coal bed gas

A construction method and technology for coalbed methane, which are applied in drilling equipment and methods, mining fluids, and earthwork drilling, etc., can solve the problems of long construction period, high production cost, and small coalbed methane output, and reduce construction and production costs. , The effect of reducing land use for construction and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

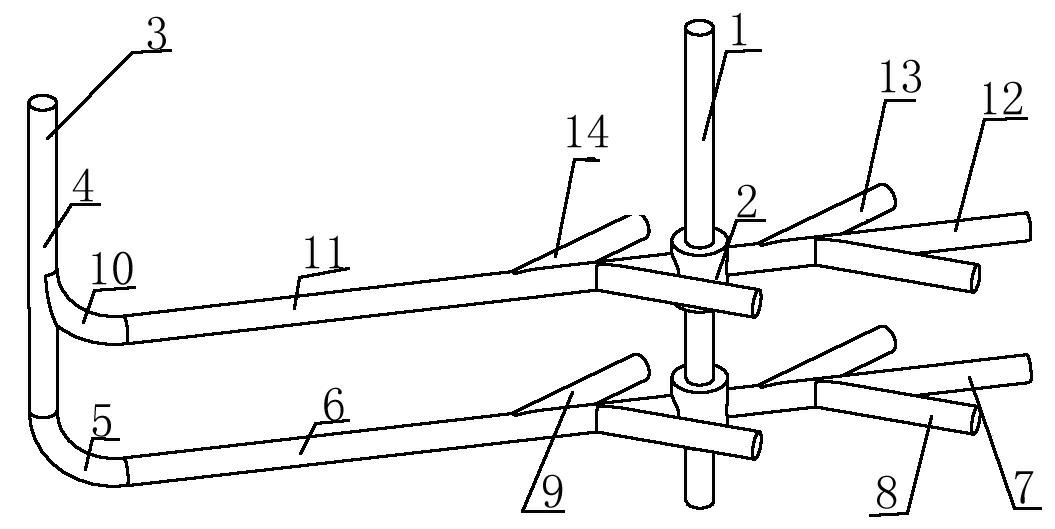

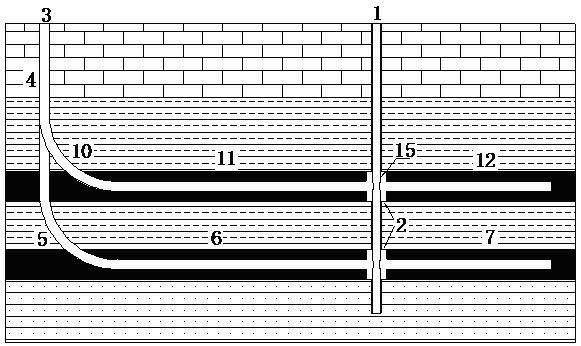

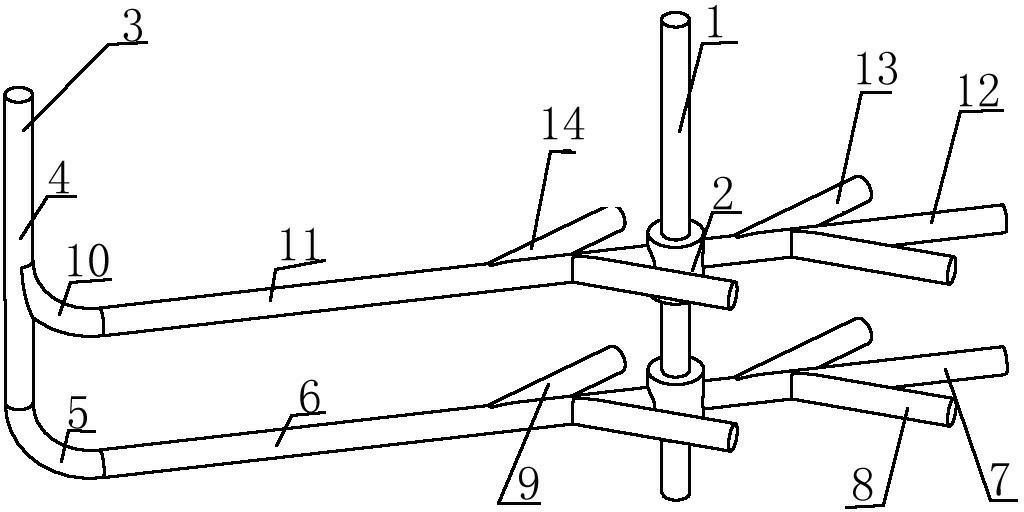

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0024] The present invention is realized through the following steps:

[0025] (1) Construct a vertical cave well 1, which is to build caves in each coal seam section where coalbed methane needs to be extracted and lower the glass fiber reinforced plastic casing 15, so as to realize the smooth docking of the far end of the horizontal well 3 and ensure the coal seam cave section 2 will not collapse after docking;

[0026] (2) Construct the vertical well section 4 of the horizontal well for remote docking, the deepest buried deflection section 5 of the lower branch and the main horizontal wellbore 6 of the lower branch, and run the technical casing on the top of the coal seam roof; continue the construction After landing and entering the horizontal section, drill along the coal seam. After docking with the vertical well cave at the far end, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com