Fast desorption meter for gas content of goal seam

A gas content and desorption technology, applied in the field of coalbed methane exploration, can solve the problems of long test time, insufficient measurement ability, and no measurement, and achieve the effect of improving the test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

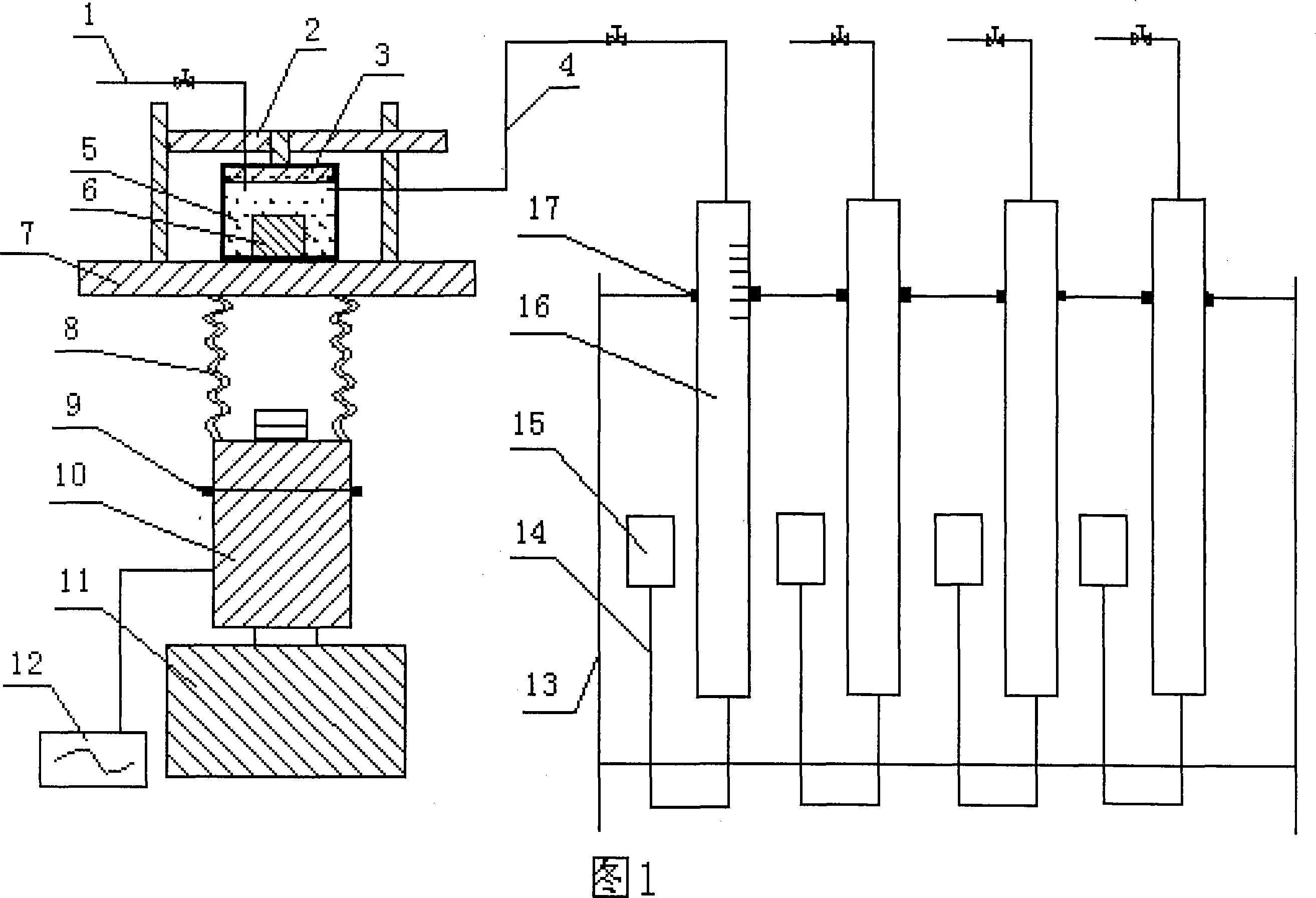

[0021] Embodiment 1: Refer to Fig. 1. The coal seam gas content rapid desorption instrument of the present invention is composed of three parts: a computer processing system, a rapid desorption system and a measurement system.

[0022] The computer acquisition and processing system includes computer processing software and data acquisition input and output.

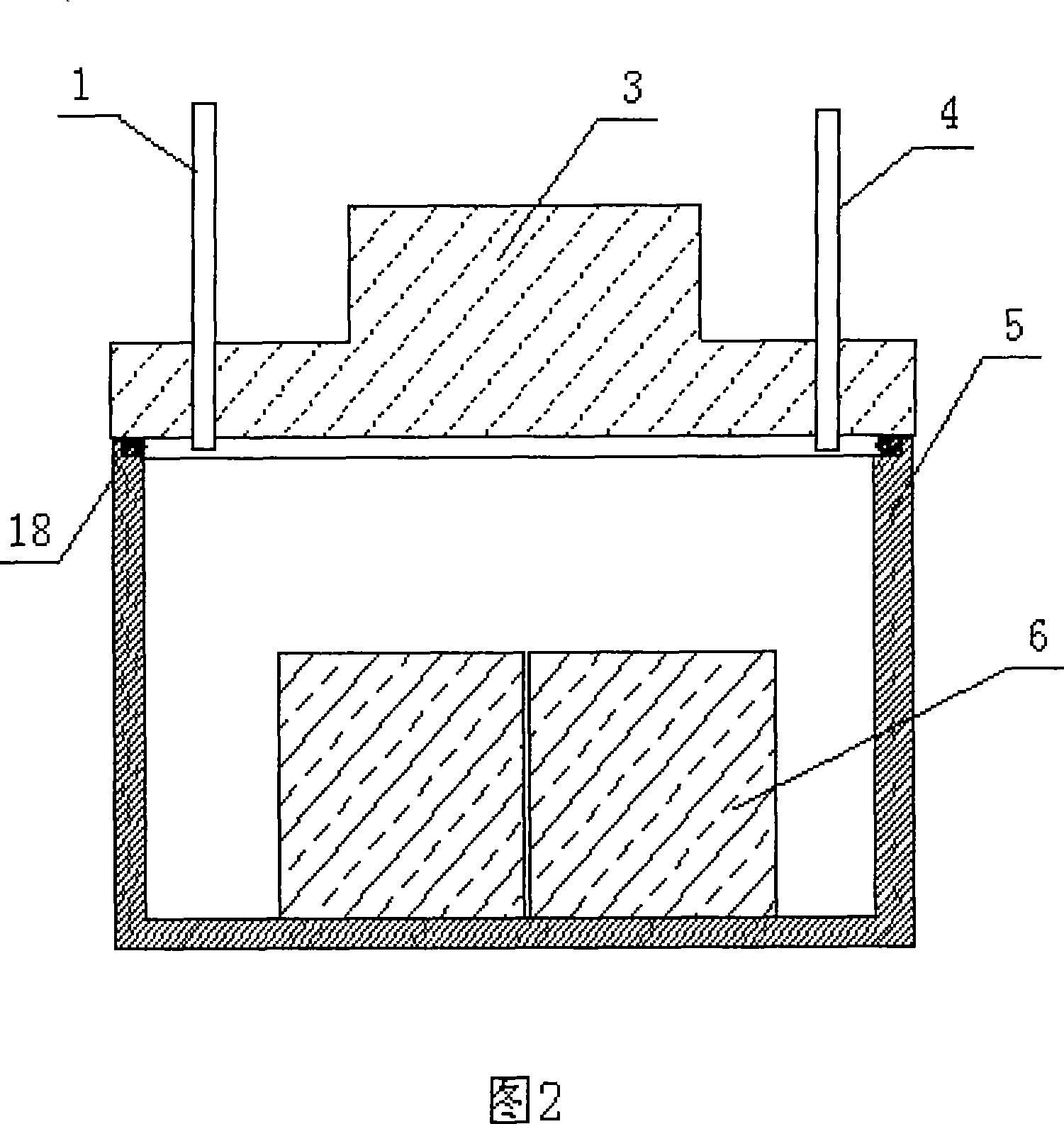

[0023] There are four fast desorption systems, which are respectively connected to the graduated cylinder 16 of the measuring system through the exhaust pipe 4. Each fast desorption system has a coal core sample sealed tank 5 and a broken sample platform. Sealing tank 5 internal diameters are 150 millimeters, and height is 50 millimeters. The structure of sealing tank 5 is to be made of tank body 19, stirring block 6, sealing cover 3; A sealing cover 3 is arranged on the top of the tank body 19, and a sealing ring 18 is arranged between the tank body 19 and the sealing cover 3. A stirring block 5 is arranged in the ai...

Embodiment 2

[0029] Embodiment 2: refer to accompanying drawing 2. The biggest difference of the fast desorption mechanism of the gas content analyzer is that there are two cylindrical stirring blocks 6 made of iron in the sealed tank 5 . In the past, we used different mechanisms such as iron block plus iron ring, discus, etc., and there were problems such as insufficient crushing and long crushing time when crushing coal samples. After two stirring blocks 6 are used to pulverize the coal sample, the two stirring blocks 6 vibrate together when the motor 10 vibrates, so that the sealed tank 5 can achieve the same crushing effect at a relatively low vibration frequency. The motor with low power is used to reduce the weight of the motor, and at the same time, the weight of the fixed base is removed, which greatly reduces the weight of the fast desorption mechanism of the whole gas content analyzer. It used to be more than 170 kilograms, but now the overall weight does not exceed 30 kilograms...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com