Catalytic deoxidation process of oxygen-contained coal bed gas

A technology for catalytic deoxidation and coalbed methane, applied in the chemical field, can solve the problems of increasing the resistance drop of the bed layer, reducing the CH recovery rate, and the large volume of the reactor equipment, and achieving the effects of avoiding the reaction temperature, improving the recovery rate, and increasing the processing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

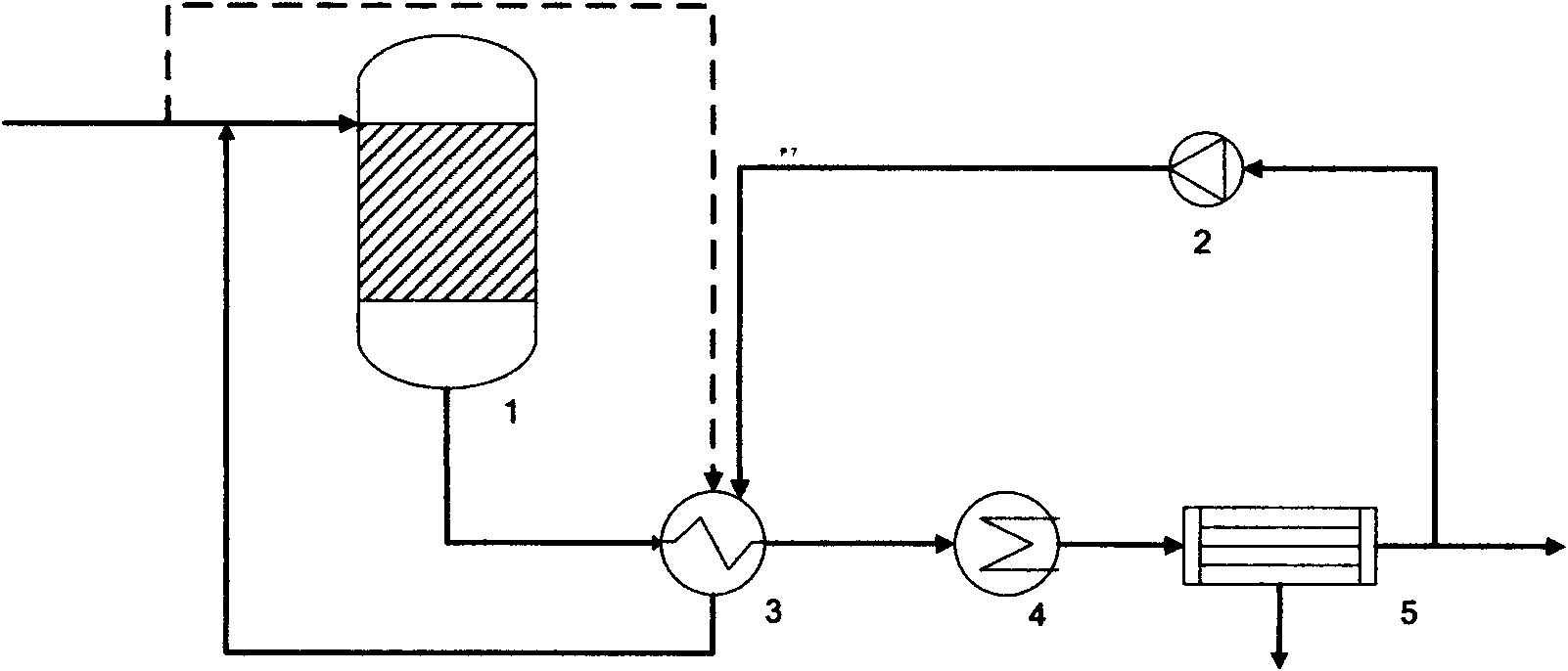

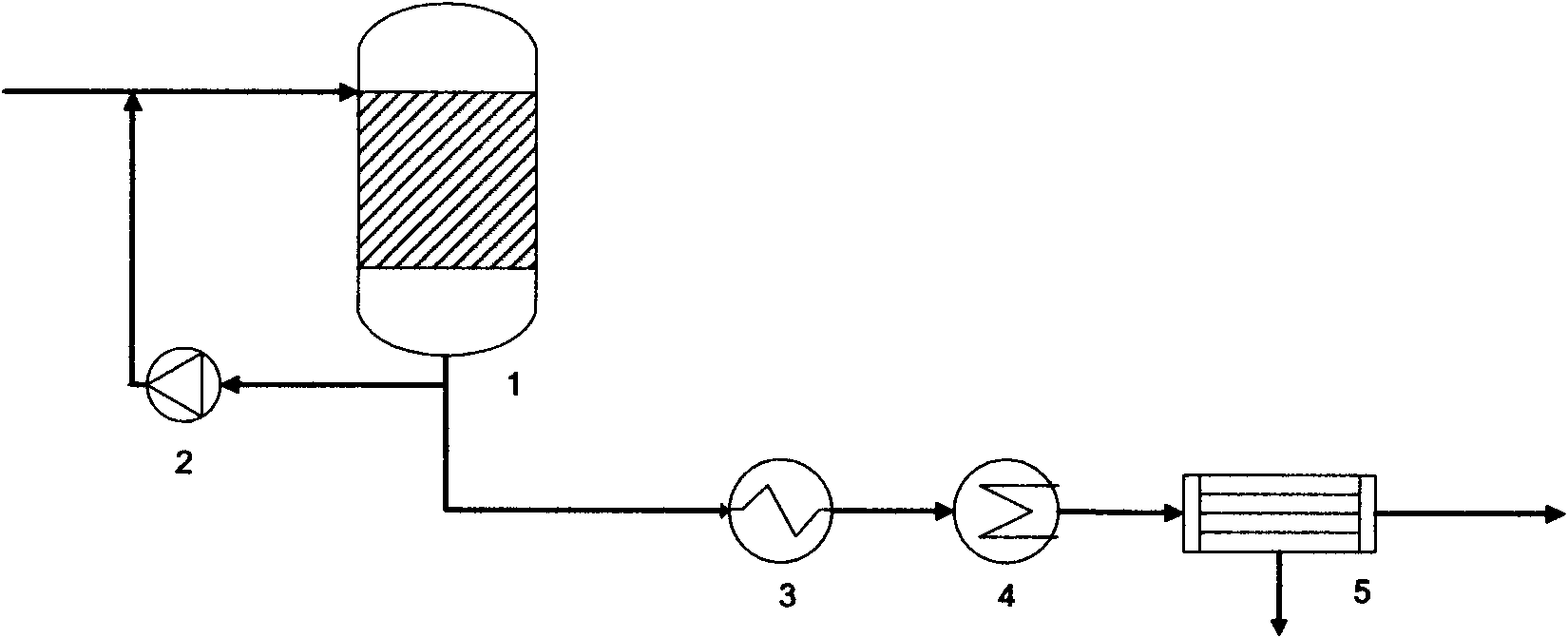

Method used

Image

Examples

Embodiment 1- Embodiment 8

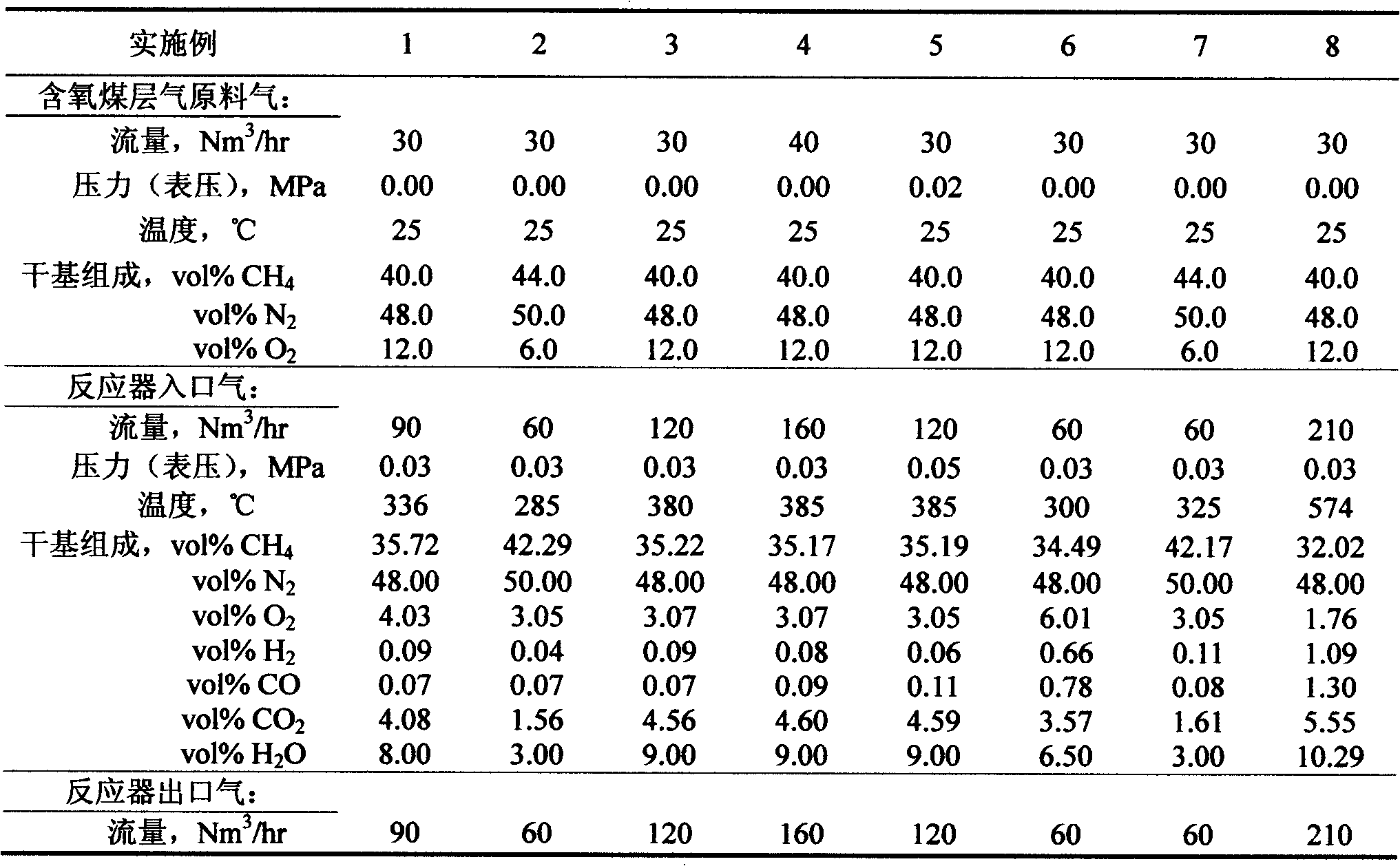

[0052] Embodiment 1-embodiment 8 has provided different coalbed methane product gas circulation modes and different coalbed methane raw material gas O in the technique of the present invention 2 Concentration, reaction bed inlet temperature, outlet temperature, inlet pressure, circulation ratio R, reaction space velocity and other operating process parameters on the composition of deoxidized coalbed methane product gas, wherein embodiment 6 and embodiment 8 are comparative examples, not included in the present invention protected list.

[0053] The catalysts used in experiments in embodiment 1-embodiment 8 are all weight percentages and consist of 0.2%Pd / 15%CeO 2 -5%La 2 o 3 / 79.8% cordierite honeycomb ceramic monolithic catalyst. CH in feed gas and product gas 4 , N 2 , CO 2 , CO and H 2 Detection by gas chromatography thermal conductivity detector; O in feed gas and product 2 by PROLINE Process mass spectrometer online detection.

[0054] In the experiment, firstl...

Embodiment 9- Embodiment 12

[0060] Embodiment 9-Example 12 give a comparison of the ignition and start-up performance of the catalytic deoxygenation reaction process system under different conditions. The catalyst used in the experiment is 0.2%Pd / 15%CeO by weight percentage 2 -5% La 2 o 3 / 79.8% cordierite honeycomb ceramic monolithic catalyst, the volume space velocity of the ignition gas source is 5,000hr -1 . It can be seen from the experimental data in Table 2 that, for the raw material gas of oxygen-containing coalbed methane (comparative example 12), under the conditions of this experiment, the deoxidation reaction can only be started if it is preheated to above 280°C. Adding a preheater to preheat the reaction raw materials before the deoxidizer undoubtedly increases the complexity of the deoxidation process. By introducing a certain amount of H into the raw gas of coal bed methane 2 , H 2 and O in coalbed methane 2 The reaction begins on the catalyst, and the combustion exotherm preheats t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com