Nanometer polymer blocking agent for drilling fluid and preparation method thereof

A technology of nano-polymer and plugging agent, applied in drilling compositions, chemical instruments and methods, etc., can solve problems such as high cost, unfavorable environmental protection, etc., achieve high conversion rate, good filtration performance, reduce The effect of filtration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

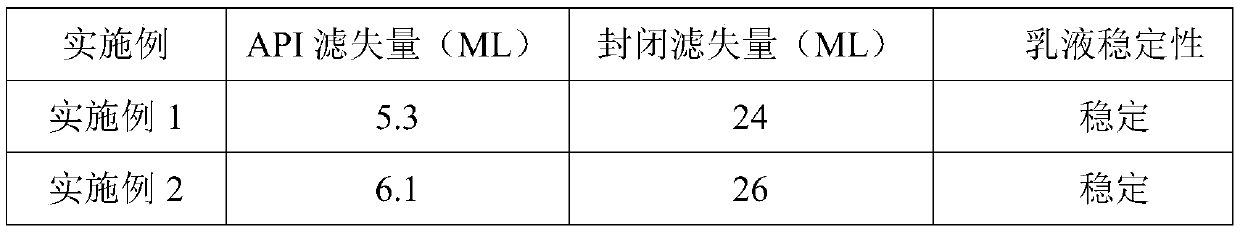

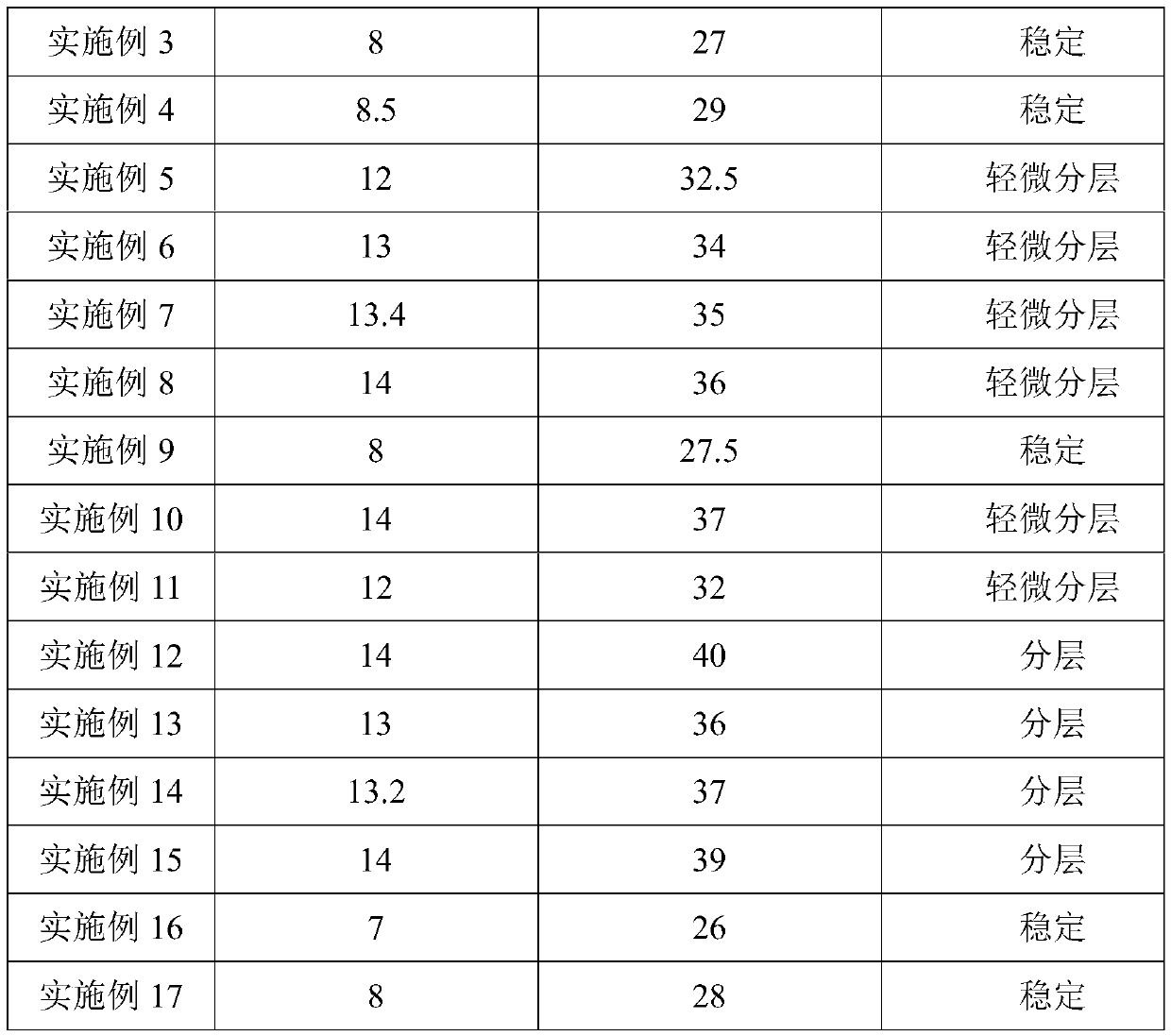

Examples

Embodiment 1

[0093] Embodiment 1 of the present invention provides a nano-polymer plugging agent for drilling fluid. In parts by weight, the preparation raw materials include 7.8 parts of acrylic acid, 11.5 parts of acrylamide, and 9.72 parts of polyethylene glycol methyl ether methacrylate ( Mn300), 4.1 parts of N-vinyl-N-(2-phenylethyl)-acetamide, 0.08 parts of potassium persulfate, 10 parts of ethylene oxide propylene oxide block copolyether, 4 parts of Tween 40, 1 part of Span 60, 3.5 parts of N,N-methylenebisacrylamide, 55 parts of water, 43 parts of white oil.

[0094] The preparation method of ethylene oxide propylene oxide block copolyether is as follows:

[0095] (1) Under normal pressure, the temperature in the reactor is controlled at 10°C, feed nitrogen to replace the air in the reactor, and add 4 parts by weight of polyethylene glycol (Mn400).

[0096] (2) Add 1 weight part of potassium hydroxide to the reactor in step 1, and stir evenly.

[0097] (3) The temperature of the ...

Embodiment 2

[0104] Embodiment 2 of the present invention provides a nano-polymer plugging agent for drilling fluid. In parts by weight, the preparation raw materials include 7.8 parts of acrylic acid, 11.5 parts of acrylamide, and 10.8 parts of polyethylene glycol methyl ether methacrylate ( Mn500), 4.1 parts of N-vinyl-N-(2-phenylethyl)-acetamide, 0.08 parts of potassium persulfate, 10 parts of ethylene oxide propylene oxide block copolyether, 4 parts of Tween 40, 1 part of Span 60, 3.5 parts of N,N-methylenebisacrylamide, 55 parts of water, 43 parts of white oil.

[0105] The preparation method of ethylene oxide propylene oxide block copolyether is as follows:

[0106] (1) Under normal pressure, the temperature in the reactor is controlled at 10°C, feed nitrogen to replace the air in the reactor, and add 4 parts by weight of polyethylene glycol (Mn400).

[0107] (2) Add 1 weight part of potassium hydroxide to the reactor in step 1, and stir evenly.

[0108] (3) The temperature of the ...

Embodiment 3

[0115] Embodiment 3 of the present invention provides a nano-polymer plugging agent for drilling fluid. In parts by weight, the preparation raw materials include 7.05 parts of acrylic acid, 10.43 parts of acrylamide, and 8.82 parts of polyethylene glycol methyl ether methacrylate ( Mn300), 3.7 parts of N-vinyl-N-(2-phenylethyl)-acetamide, 0.05 parts of potassium persulfate, 7 parts of ethylene oxide propylene oxide block copolyether, 5.6 parts of Tween 40, 1.4 parts of Span 60, 2 parts of N,N-methylenebisacrylamide, 50 parts of water, 40 parts of white oil.

[0116] The preparation method of ethylene oxide propylene oxide block copolyether is as follows:

[0117] (1) Under normal pressure, the temperature in the reactor is controlled at 10°C, feed nitrogen to replace the air in the reactor, and add 4 parts by weight of polyethylene glycol (Mn400).

[0118] (2) Add 1 weight part of potassium hydroxide to the reactor in step 1, and stir evenly.

[0119] (3) The temperature of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com