Water-based drilling fluid high-temperature-resistant tackifying rheology modifier, and preparation method thereof, and drilling fluid

A technology of water-based drilling fluid and high temperature resistance, applied in the field of oilfield drilling fluid, can solve problems such as insufficient temperature resistance, and achieve the effects of improving drilling efficiency, excellent thermal stability, and improving lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

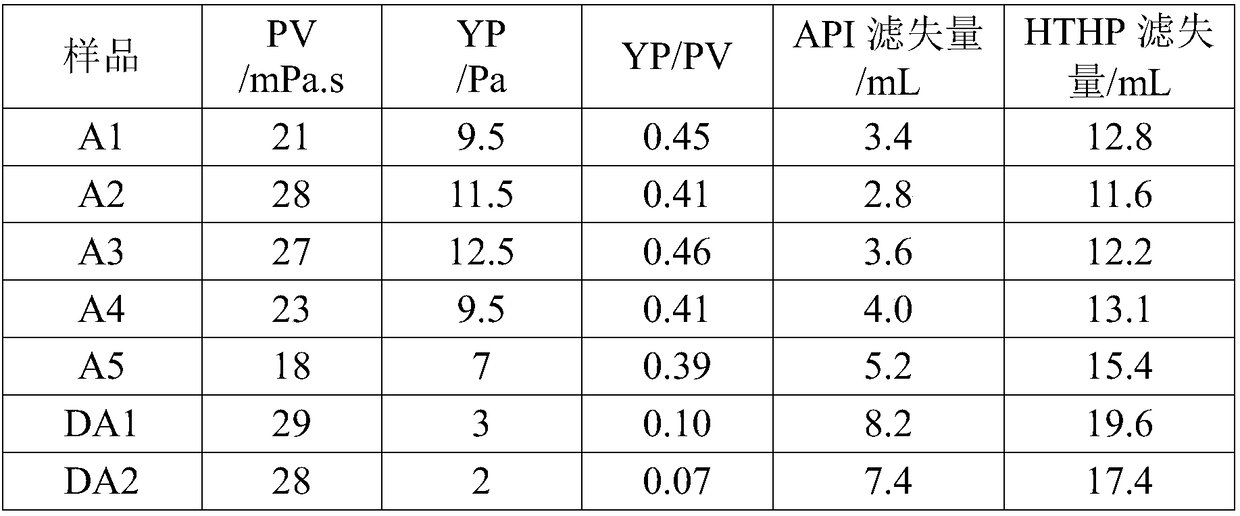

Examples

Embodiment 1

[0054] Add 100 g of 0.25 mol / L NaOH aqueous solution in the beaker, then add 20 g of potato starch. Stir the dispersion at high speed at 50°C until all the starch is dissolved, then add 1 g of epichlorohydrin to the beaker. After fully mixing and standing still, the water phase in the mixed solution was poured into a three-necked flask, and 5 g of Span-80 and 100 g of cyclohexane were added to the flask. The obtained white emulsion was stirred at high speed (20000 rpm) for 10 min at 35° C., and then continued to react at room temperature with low speed stirring (800 rpm) for 20 h. After the reaction was complete, the emulsion was transferred to a separatory funnel, and the aqueous phase containing the starch microgel was separated with 250 mL of acetic acid. The obtained product aqueous solution was centrifuged to separate the solid phase, washed repeatedly with deionized water and ethanol several times, and then vacuum-dried at 60° C. for 16 hours to finally obtain powdery s...

Embodiment 2

[0056] Add 100 g of 0.25 mol / L NaOH aqueous solution in the beaker, then add 20 g of potato starch. Stir the dispersion at high speed at 50 °C until all the starch is dissolved, then add 2 g of epichlorohydrin to the beaker. After fully mixing and standing still, the water phase in the mixed solution was poured into a three-necked flask, and 5 g of Span-80 and 100 g of cyclohexane were added to the flask. The obtained white emulsion was stirred at high speed (20000 rpm) for 10 min at 35° C., and then continued to react at room temperature with low speed stirring (800 rpm) for 20 h. After the reaction was complete, the emulsion was transferred to a separatory funnel, and the aqueous phase containing the starch microgel was separated with 250 mL of acetic acid. The obtained product aqueous solution was centrifuged to separate the solid phase, washed repeatedly with deionized water and ethanol several times, and then vacuum-dried at 60° C. for 16 hours to finally obtain powdery ...

Embodiment 3

[0058] Add 100 g of 0.25 mol / L NaOH aqueous solution in the beaker, then add 20 g of potato starch. Stir the dispersion at high speed at 50°C until all the starch is dissolved, then pour 6g of epichlorohydrin into the beaker. After fully mixing and standing still, the water phase in the mixed solution was poured into a three-necked flask, and 5 g of Span-80 and 100 g of cyclohexane were added to the flask. The obtained white emulsion was stirred at high speed (20000 rpm) for 10 min at 35° C., and then continued to react at room temperature with low speed stirring (800 rpm) for 20 h. After the reaction was complete, the emulsion was transferred to a separatory funnel, and the aqueous phase containing the starch microgel was separated with 250 mL of acetic acid. The obtained product aqueous solution was centrifuged to separate the solid phase, washed repeatedly with deionized water and ethanol several times, and then vacuum-dried at 60° C. for 16 hours to finally obtain powdery...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com