Preparation method of polyamide inhibitor for drilling fluid

A technology of polyamide and drilling fluid, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of limited adsorption capacity, loss of inhibitory effect, etc., and achieve small influence on rheology, good inhibitory effect, and rolling recovery rate improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Dodecyl primary amine is dissolved in isopropanol, then dimethyl maleate is added to the alcohol solution, and mixed evenly.

[0025] Adjust the temperature to 50°C and react for 20 hours to obtain an intermediate product.

[0026] Add monoethanolamine to the intermediate product, add sodium hydroxide as a catalyst, heat up to reflux temperature, and react for 12 hours.

[0027] Isopropanol was distilled off to obtain a yellow viscous liquid as the product.

Embodiment 2

[0029] Decyl primary amine is dissolved in isopropanol, and then diethyl maleate is added to the alcohol solution to make it evenly mixed.

[0030] Adjust the temperature to 70°C and react for 15 hours to obtain an intermediate product.

[0031] Diethanolamine was added to the intermediate product, potassium hydroxide was added as a catalyst, the temperature was raised to reflux temperature, and the reaction was carried out for 12 hours.

[0032] Isopropanol was distilled off to obtain a yellow viscous liquid as the product.

Embodiment 3

[0034] Dissolve octadecyl primary amine in tert-butanol, then add diisobutyl maleate into the alcohol solution, and mix well.

[0035] Adjust the temperature to 60°C and react for 20 hours to obtain an intermediate product.

[0036] Add N-hydroxyethylethylenediamine to the intermediate product, add sodium hydroxide as a catalyst, heat up to reflux temperature, and react for 12 hours.

[0037] The tert-butanol was evaporated to obtain a yellow viscous liquid as the product.

[0038] Embodiment performance evaluation method

[0039] 1. Polyamide inhibitor rolling recovery test

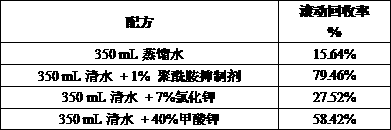

[0040] Get 4 parts of 350mL distilled water, three parts of which add 1% polyamide inhibitor (embodiment 1), 7% commonly used inhibitor potassium chloride and 40% commonly used inhibitor potassium formate, in a low speed stirrer (1000rpm / min) and stirred for 10 min. Pour four parts of liquid into the aging tank, and then add 50g of mud shale cuttings respectively. The rolling recoveries of the four...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com