Method for preparing polyepichlorohydrin-diethanol amine anti-collapse inhibitor in laboratory

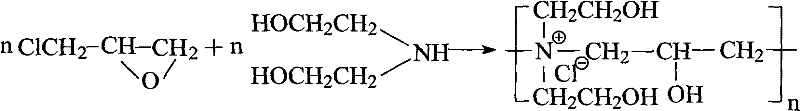

A polyepichlorohydrin and epichlorohydrin technology, which is applied in the field of petroleum drilling fluids, can solve the problems of difficult control of system rheology, complicated preparation process, and difficulty in meeting the needs of shale drilling wellbore stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Laboratory preparation of polyepichlorohydrin-diethanolamine anti-slump inhibitor

[0040] Preparation of raw material chemicals in the first step

[0041] According to the number of parts by volume, each part should not be less than 1mL, and the preparation is as follows:

[0042] 10 parts of water;

[0043] 20 parts of epichlorohydrin;

[0044] 20 parts of diethanolamine;

[0045] The second step is a low temperature water bath

[0046] In a 150mL three-necked flask, each mouth of the three-necked flask is used to place a thermometer, agitator and add raw material chemicals respectively. Take 10mL of water and add it to the three-necked flask, and place the three-necked flask in an ice-water bath to control its temperature at 25 Below ℃;

[0047] The third step is to add diethanolamine

[0048] Add 20mL of diethanolamine to the three-necked flask required by the previous step, and stir for 10 minutes until the diethanolamine and water are completely mixed and un...

Embodiment 2

[0055] Example 2: Laboratory preparation of polyepichlorohydrin-diethanolamine anti-slump inhibitor

[0056] Preparation of raw material chemicals in the first step

[0057] According to the number of parts by volume, each part should not be less than 1mL, and the preparation is as follows:

[0058] 20 parts of water;

[0059] 30 parts of epichlorohydrin;

[0060] 30 parts of diethanolamine;

[0061] The second step is a low temperature water bath

[0062] In a 150mL three-necked flask, each mouth of the three-necked flask is used to place a thermometer, a stirrer and add raw materials, respectively. Take 20mL of water and add it to the three-necked flask. Below ℃;

[0063] The third step is to add diethanolamine

[0064]Add 30mL of diethanolamine to the three-necked flask required by the previous step, and stir for 10 minutes until the diethanolamine and water are completely mixed and homogenous. During this period, keep a low-temperature water bath to keep the temperat...

Embodiment 3

[0071] Example 3: Laboratory preparation of polyepichlorohydrin-diethanolamine anti-slump inhibitor

[0072] Preparation of raw material chemicals in the first step

[0073] According to the number of parts by volume, each part should not be less than 1mL, and the preparation is as follows:

[0074] 10 parts of water;

[0075] 20 parts of epichlorohydrin;

[0076] 20 parts of diethanolamine;

[0077] The second step is a low temperature water bath

[0078] In a 150mL three-necked flask, each mouth of the three-necked flask is used to place a thermometer, a stirrer and add raw materials, respectively. Take 10mL of water and add it to the three-necked flask. Below ℃;

[0079] The third step is to add diethanolamine

[0080] Add 20mL of diethanolamine to the three-necked flask required by the previous step, and stir for 10 minutes until the diethanolamine and water are completely mixed and homogenous. During this period, keep a low-temperature water bath to keep the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com