Temperature-resistant salt-resistant nano anti-collapse filtrate reducer for drilling fluid and preparation method thereof

A technology of temperature resistance and salt resistance and fluid loss control agent, which is applied in the field of drilling fluid and completion fluid, and can solve problems such as poor resistance to salt.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

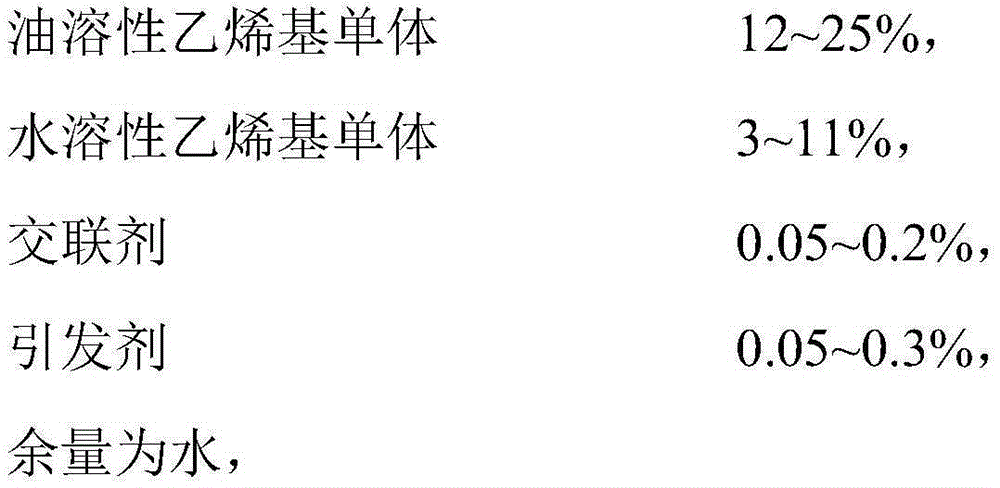

Embodiment 1

[0022] Add 100g of distilled water into a 250mL three-neck round bottom flask, heat it in a water bath to 65°C, then add 30g of methyl methacrylate, 3g of N-vinylpyrrolidone, 8g of 2-acrylamide-2-methylpropanesulfonic acid and 0.2g of divinyl Base benzene, nitrogen protection, high-speed stirring for 15min, the stirring speed is 300-400r / min, then add 0.2g of initiator potassium persulfate, continue high-speed stirring (300-400r / min), water bath temperature control between 65℃~70℃ , reacted for 6 hours, and after the reaction was completed, the obtained emulsion was spray-dried to obtain a high-temperature and salt-resistant polymer microsphere anti-slump fluid loss additive.

Embodiment 2

[0024] Add 100g of distilled water to a 250mL three-neck round bottom flask, heat it in a water bath to 75°C, then add 15g of methyl acrylate, 2g of N-vinylpyrrolidone, 5g of 2-acrylamide-2-methylpropanesulfonic acid and 0.1g of divinylbenzene , nitrogen protection, high-speed stirring for 15 minutes, the stirring speed is 300 ~ 400r / min, then add 0.1g of initiator potassium persulfate, continue high-speed stirring (300 ~ 400r / min), water bath temperature control between 75 ° C -80 ° C, the reaction After 4 hours, after the reaction is completed, the obtained emulsion is spray-dried to obtain a high-temperature resistant polymer microsphere anti-slump fluid loss additive.

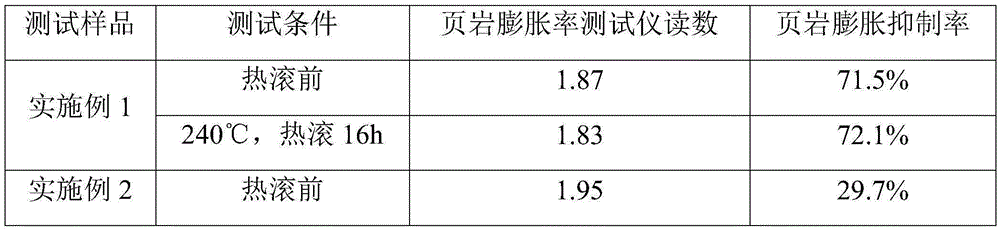

[0025] Performance evaluation:

[0026] (1) Macrostructure and microstructure:

[0027] The polymer microsphere anti-slump fluid loss agent obtained in the implementation of 1-2 is a white powdery solid in appearance.

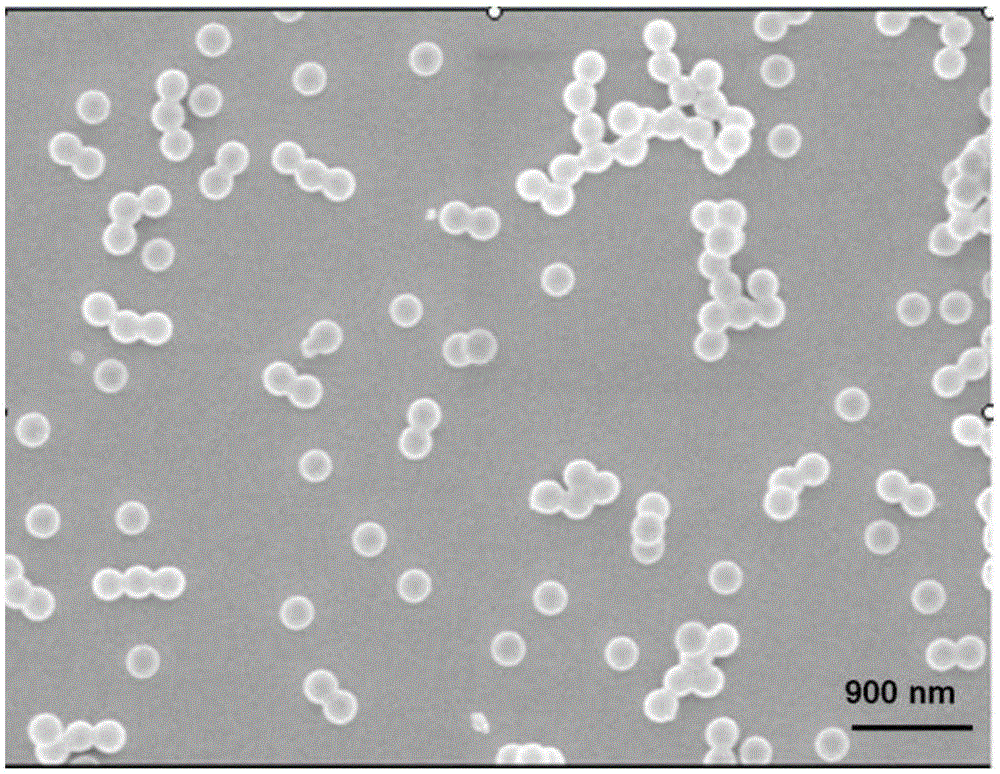

[0028] Such as figure 1 Shown are scanning electron micrographs of the temperature-re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com