Applications of aluminum salt complex in preparation of drilling fluid, and drilling fluid

A technology of drilling fluids and complexes, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve problems such as low permeability, inability to effectively improve the compressive strength of rock cores, and poor wellbore stability. Achieving good wall-reinforcement ability, improving wellbore wall stability, and increasing compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] In the reaction vessel, add 13.334g of aluminum chloride into 100g of water, fully dissolve, slowly add 10g of ammonium fluoride under stirring state, white turbidity appears, control pH value to 4, complexation temperature is 10°C, stir for 2 hours, static After standing for 1 h, a clear solution appeared in the upper layer, and a white precipitate appeared at the bottom of the container. After filtering, the obtained solid was dried at 60° C. to obtain 23 g of the target product in the form of white powder.

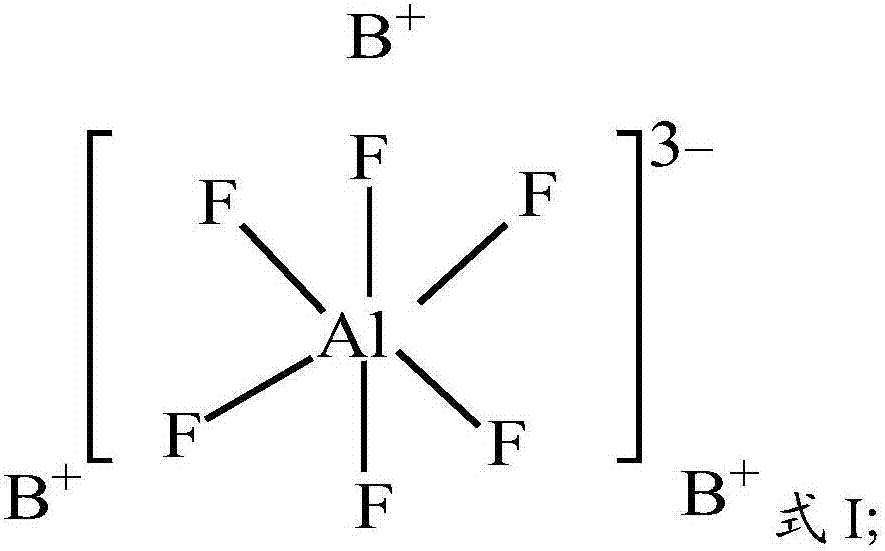

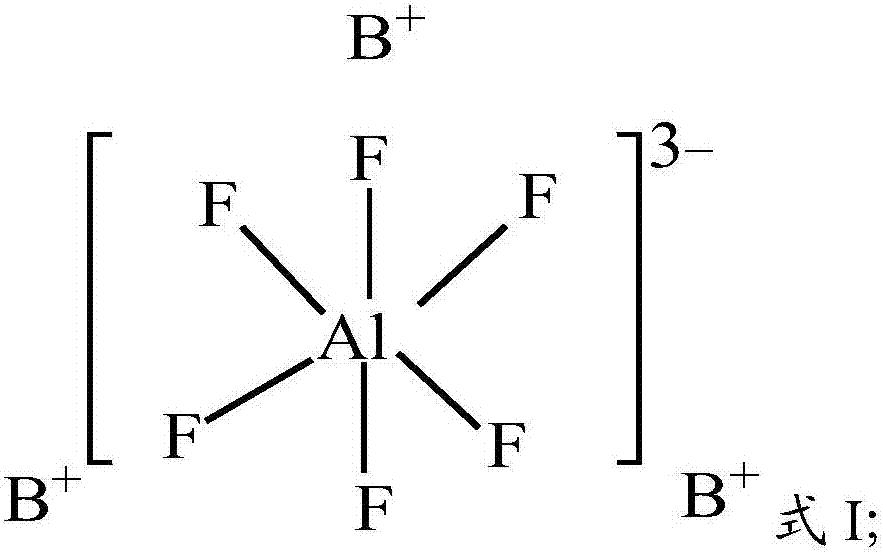

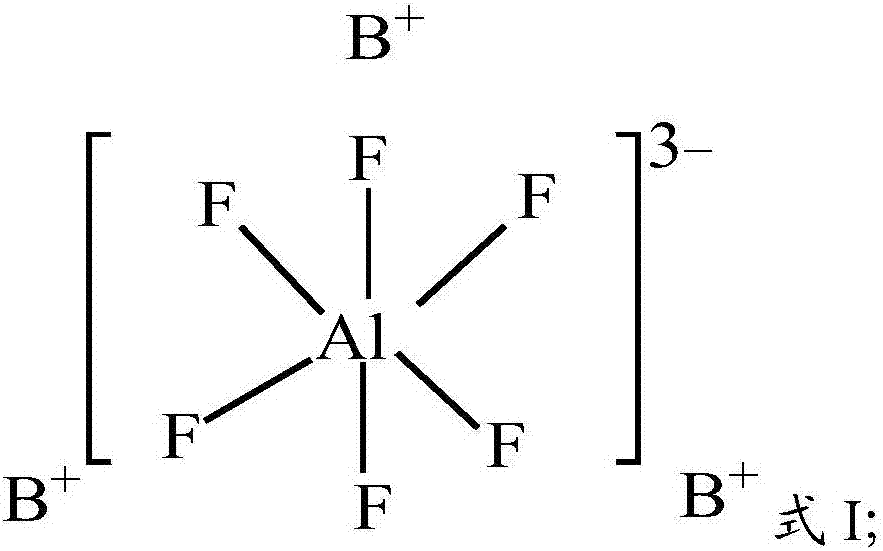

[0042] The product is a complex formed by the two compounds of aluminum chloride and ammonium fluoride, which is an aluminum salt complex with the general formula of formula I, which contains complexed aluminum ions, and B in formula I + for NH 4 + . At room temperature, the solubility of the product in an aqueous solution with a pH value of 8-10 is 15-50 g / L.

Embodiment 2

[0044] In the reaction vessel, add 13.334g of aluminum chloride into 100g of water, fully dissolve, slowly add 20.0g of potassium fluoride under stirring state, white turbidity appears, control pH value to 5, complexation temperature to 20°C, stir for 2 hours, After standing for 1 h, a clear solution appeared in the upper layer, and a white precipitate appeared at the bottom of the container. After filtering, the obtained solid was dried at 60° C. to obtain 30 g of the target product in the form of white powder.

[0045] The product is a complex formed by these two compounds of aluminum chloride and potassium fluoride, which is an aluminum salt complex with the general formula of formula I, which contains complexed aluminum ions, and B in formula I + for K + . At room temperature, the solubility of the product in an aqueous solution with a pH value of 8-10 is 15-50 g / L.

Embodiment 3

[0047] In the reaction vessel, add 13.334g of aluminum chloride into 100g of water and fully dissolve it. Slowly add 25.2g of sodium fluoride under stirring, and white turbidity will appear. Control the pH value to 6, and the complexation temperature to 30°C. Stir for 3 hours. After standing for 2 hours, a clear solution appeared in the upper layer, and a white precipitate appeared at the bottom of the container. After filtering, the obtained solid was dried at 60° C. to obtain 37 g of the target product in the form of white powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com