Biquaternary ammonium salt compound and application thereof in solid-phase chemical cleaning agent

A double quaternary ammonium salt, solid-phase chemistry technology, applied in the field of oil drilling, can solve the problems such as can not effectively inhibit the hydration expansion and dispersion of drilling cuttings, destroy the colloidal stability of drilling fluid, reduce the solid phase removal efficiency, etc. High phase removal efficiency, high shale rolling recovery rate, and good inhibition ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

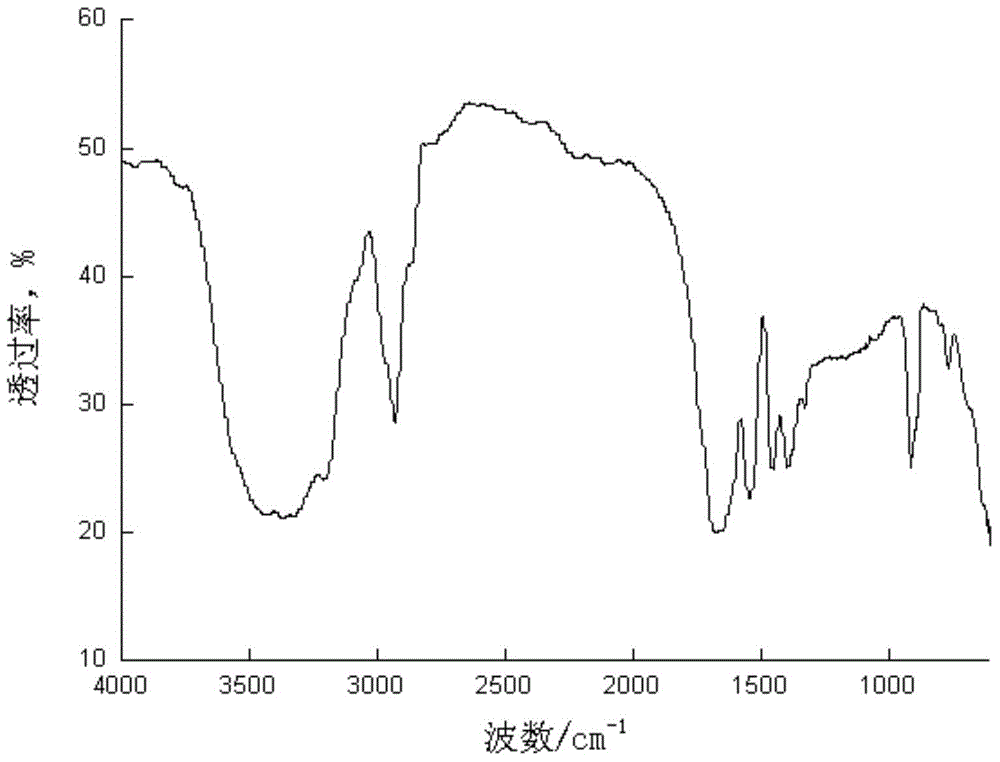

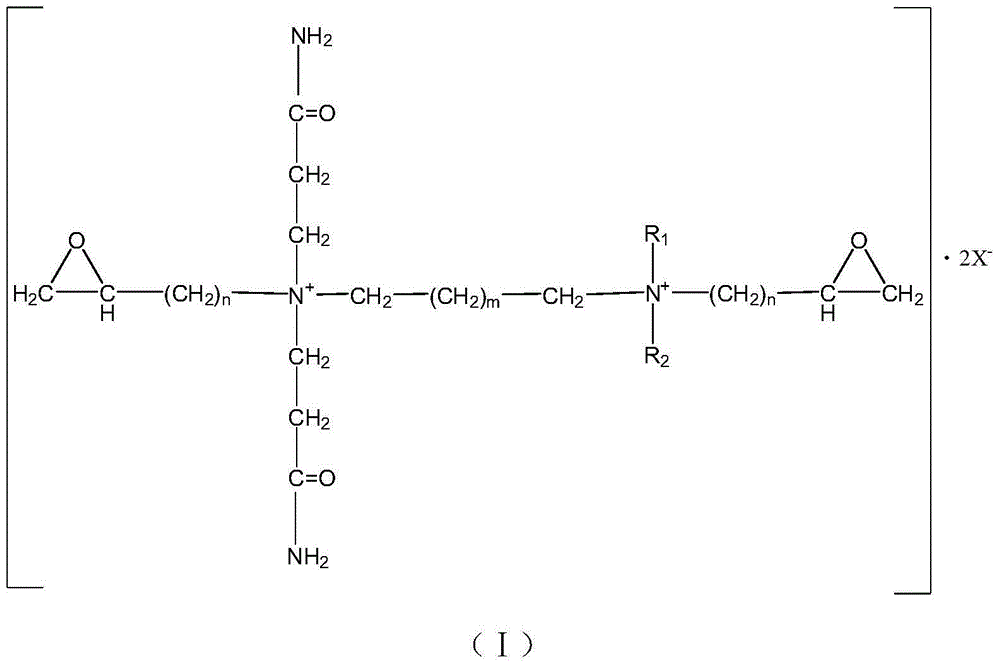

[0051] Add 517 grams of water and 144 grams (2 moles) of acrylamide into the reaction kettle, stir until the acrylamide is completely dissolved, then add 102.2 grams (1 mole) of dimethylaminopropylamine, stir for 5 to 10 minutes, and React at 20°C for 16 hours; after the reaction time is up, heat up to 30°C, add 0.431 grams of catalyst benzyltriethylammonium chloride, and then slowly add 185 grams (2 moles) of epichlorohydrin to the reaction kettle dropwise , keep the temperature of the reaction system within 35°C during the dropwise addition; after adding epichlorohydrin, the temperature is raised to 70°C, and the reaction is continued for 1 hour. After the reaction time is up, the reaction product is dried and pulverized to obtain the structural formula: The diquaternary ammonium salt compound shown in (II).

[0052]

[0053] The appearance of the compound obtained in this example is white or slightly yellow crystal, which is very easy to absorb moisture, and its aqueous ...

Embodiment 2

[0056] Add 668 grams of water and 144 grams (2 moles) of acrylamide into the reaction kettle, stir until the acrylamide is completely dissolved, then add 107.3 grams (1.05 moles) of dimethylaminopropylamine, stir for 5 to 10 minutes, and set the temperature at 0 to 20°C Reacted for 32 hours; after the reaction time reached, the temperature was raised to 30°C, 4.31g of catalyst tetrabutylammonium bromide was added, and then 194.25 grams (2.1 moles) of epichlorohydrin was slowly added dropwise to the reactor, and the dropwise addition process kept The temperature of the reaction system is within 35°C; after the addition of epichlorohydrin, the temperature is raised to 60°C, and the reaction is continued for 3 hours. After the reaction time is up, the reaction product is dried and pulverized to obtain a diquaternary ammonium compound.

Embodiment 3

[0058] Add 517 grams of water and 144 grams (2 moles) of acrylamide into the reaction kettle, stir until the acrylamide is completely dissolved, then add 102.2 grams (1 mole) of dimethylaminopropylamine, stir for 5 to 10 minutes, and store at 0 to 20°C React for 24 hours; after the reaction time reaches 30°C, add 2.2 grams of catalyst tetrabutylammonium chloride, and then slowly add 185 grams (2 moles) of epichlorohydrin to the reactor. Keep the temperature of the reaction system within 35°C; raise the temperature to 65°C after adding the epichlorohydrin, and continue the reaction for 5 hours. After the reaction time is up, dry and pulverize the reaction product to obtain the bis-quaternary ammonium compound.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com