Shale strong-inhibition nano plugging water-based drilling fluid

A water-based drilling fluid, strong suppression technology, applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of poor wellbore stability, high temperature gelation, poor pollution resistance, etc., and achieve strong suppression plugging capacity, reduced collapse pressure, good plugging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

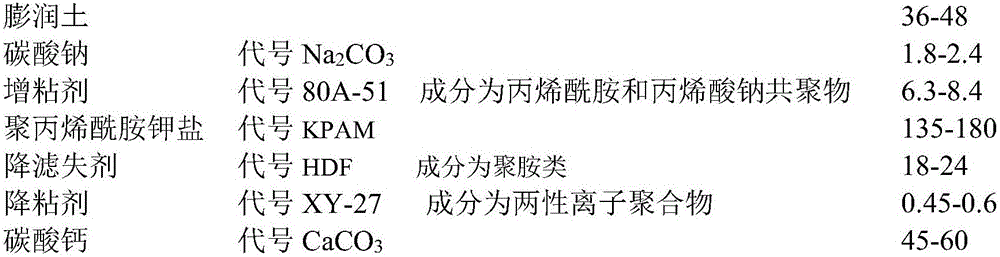

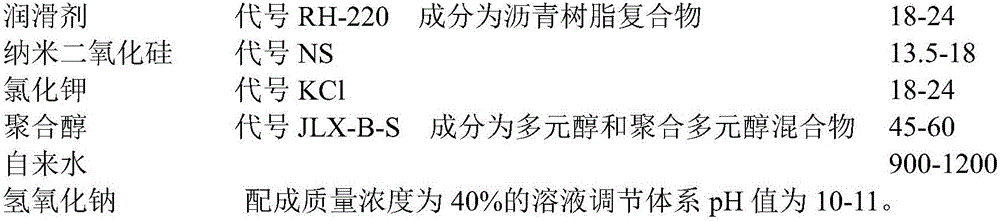

[0018] Example 1: Preparation method of water-based drilling fluid with strong inhibitory nano-plugging for shale.

[0019] The preparation method of the water-based drilling fluid with strong inhibitory nano-sealing for shale is:

[0020] First measure 1000 grams of tap water and heat it up to 70°C, add 40 grams of bentonite and stir for 10 minutes under electric stirring at a low speed of 500r / min; then add 2 grams of sodium carbonate, stir for 20 minutes, pre-hydrate for 24 hours at normal temperature and pressure, and then stir for 15 minutes Add 7 grams of tackifier 80A-51 and stir for 5 minutes; then add 150 grams of polyacrylamide potassium salt and stir for 10 minutes, add 20 grams of fluid loss reducer HDF and stir for 10 minutes, add 0.5 grams of viscosity reducer XY27 and stir for 5 minutes, add Stir 50 grams of calcium carbonate powder (1250 mesh: 1500 mesh: 2000 mesh = 1:3:1) for 20 minutes, add 50 grams of polyalcohol and stir for 5 minutes; then measure 200 gram...

example 2

[0021] Example 2: The rolling recovery rate of the drilling fluid system of the present invention was measured by using an XGRL-2 type roller heating furnace.

[0022] (1) Rolling recovery rate experiment

[0023] Table 2 Rolling recovery test results of water-based drilling fluid system with strong inhibitory nano-plugging for shale

[0024] Drilling Fluid Formula Experimental conditions Recovery mass (g) Recovery rate(%) Clear water + 50g red bed soil 180℃ / 16h 5.64 11.28 Strong inhibitory nano drilling fluid system for shale+50g 180℃ / 16h 49.16 98.32

[0025] Note: 1) The red layer soil is Sichuan red layer soil debris, and the shale outcrop is Chang 7 shale outcrop, all of which are 6-10 mesh, and the recovery rate is over 40 mesh; 2) The results in the table are all 2 times The mean of the experimental data.

[0026] (2) Linear expansion experiment

[0027] Table 3 Experimental results of linear expansion of water-based drilling fluid s...

example 3

[0030] Example 3: The plugging performance of the drilling fluid system of the present invention was evaluated by using the simulated shale formation permeability mud cake.

[0031] Table 4 Plugging experiment results of water-based drilling fluid system with strong inhibitory nano-plugging for shale

[0032]

[0033] Note: 1) The plugging agent refers to calcium carbonate, polyalcohol, and nano-silica; 2) The results in the table are the average of the data of two experiments.

[0034] From Table 2, Table 3, and Table 4, the rolling recovery rate and linear expansion rate experiments of the shale inhibitory nano-plugging water-based drilling fluid show that the rolling recovery rate is above 98.32%, and the 16h linear expansion rate is only 22.56%. Inhibition of hydration dispersion and expansion, and when the system contains nano-silica and calcium carbonate with a certain particle size ratio, the permeability of the simulated formation is reduced by 48.59%, which greatly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com