Drilling fluid lubricant composition and preparation method thereof and water-based drilling fluid and application thereof

A technology of lubricant composition and water-based drilling fluid, which is applied in the field of drilling fluid, can solve the problems that the lubricant does not have anti-wear and anti-friction properties, and the lubricant does not have high temperature resistance, so as to improve oxidation stability and lubricating performance, lubricate The effect of excellent performance and rich source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

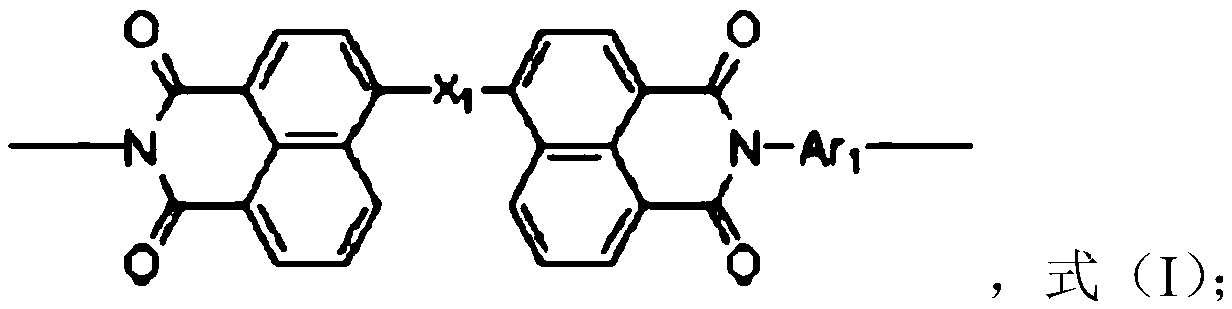

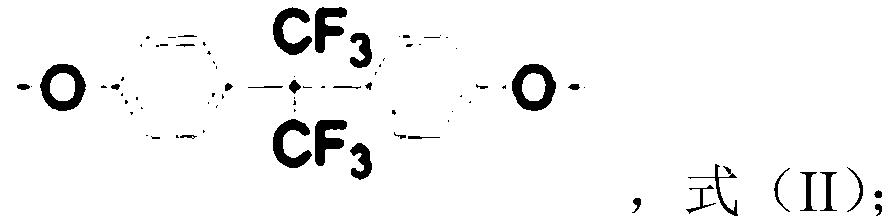

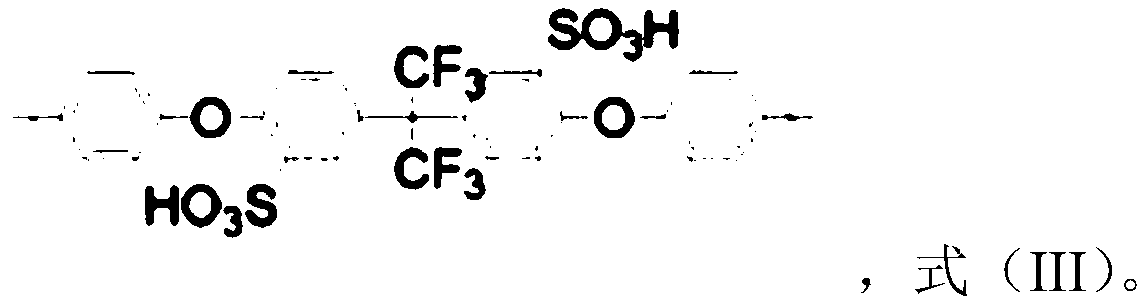

Method used

Image

Examples

preparation example Construction

[0032] According to the present invention, the preparation method of the capsule comprises the following steps:

[0033] (a) ultrasonically oscillating sulfonated polyimide, water and a second dispersant to obtain a dispersion;

[0034] (b) mixing and stirring the phenolic resin prepolymer and the dispersion liquid, and then performing microwave curing.

[0035] In step (a), sulfonated polyimide, water and a second dispersant may be added to an emulsifier equipped with an ultrasonic cleaner and a stirrer, and the ultrasonic oscillation may be carried out at room temperature , for example, the temperature is 18-25°C, and the ultrasonic oscillation time can be 20-45min to disperse the sulfonated polyimide in water; preferably, the mass of the amount of sulfonated polyimide, water and the second dispersant The ratio is (2-3):(10-15):1. In addition, the second dispersant can be sodium dodecylbenzenesulfonate, sodium dodecylbenzenesulfate, polyoxyethylene sorbitan monooleate, sod...

Embodiment 1

[0089] This example is used to illustrate the preparation of lubricant composition and water-based drilling fluid by the method of the present invention.

[0090] The lubricant composition of this embodiment includes the following components and parts by weight: 32 parts by weight of modified vegetable oil, 45 parts by weight of biodiesel, 6 parts by weight of extreme pressure antiwear agent, sulfonated polyimide microcapsules coated with phenolic resin ( Capsules) 9 parts by weight, 3 parts by weight of the first dispersant and 7 parts by weight of the defoamer.

[0091] Wherein, modified vegetable oil is epoxy-modified rapeseed oil, and the preparation method of this epoxy-modified rapeseed oil comprises the following steps:

[0092] Step (A): Add 18g of rapeseed oil into the reactor, then dropwise add 6g of potassium hydroxide methanol solution with a mass concentration of 6%, react at 60°C for 1h after the drop, wash until neutral after the reaction, and remove water Drie...

Embodiment 2

[0111] This example is used to illustrate the preparation of lubricant composition and water-based drilling fluid by the method of the present invention.

[0112] The lubricant composition of this embodiment includes the following components and parts by weight: 40 parts by weight of modified vegetable oil, 50 parts by weight of biodiesel, 7 parts by weight of extreme pressure antiwear agent, 12 parts by weight of sulfonated polyimide microcapsules coated with phenolic resin parts by weight, 4 parts by weight of dispersant and 8 parts by weight of defoamer.

[0113] Wherein, modified vegetable oil is epoxy-modified rapeseed oil, and the preparation method of this epoxy-modified rapeseed oil comprises the following steps:

[0114] Step (A): Add 16 g of rapeseed oil into the reactor, then drop 5 g of potassium hydroxide methanol solution with a mass concentration of 7%, react at 62° C. for 1.5 h after the drop, wash until neutral after the reaction, remove Drying with water yie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com